-

Sarah

Hi there! Welcome to my shop. Let me know if you have any questions.

Sarah

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

Streamlining Your Manufacturing Process with the Right Tool Storage Solutions

2025-10-29 13:55:54

In today’s competitive manufacturing landscape, manufacturing process improvement has become essential for maintaining market leadership and profitability. One often-overlooked aspect of operational excellence is tool storage solutions – the strategic organization and management of tools that directly impact production efficiency, quality control, and workplace safety. This comprehensive guide explores how the right tool storage systems can transform your manufacturing processes, eliminate bottlenecks, and create a more productive, efficient operation.

The Critical Role of Tool Storage in Manufacturing Excellence

Understanding the Manufacturing Tool Management Challenge

Modern manufacturing facilities face complex tool management challenges that significantly impact operational performance:

Tool accessibility issues: Workers lose valuable production time searching for appropriate tools

Inventory management complexity: Difficulty tracking tool location, condition, and availability

Workflow interruptions: Missing or poorly organized tools disrupting production schedules

Quality control impacts: Using incorrect or poorly maintained tools affecting product quality

Safety concerns: Disorganized tools creating workplace hazards and injury risks

Quantifying the Impact of Inefficient Tool Storage

Industry research reveals compelling statistics about tool storage inefficiencies:

Time loss: Average manufacturing workers spend 12-18 minutes daily searching for tools

Production delays: Tool-related issues cause 15-20% of unscheduled production downtime

Quality costs: Poor tool management contributes to 8-12% of quality-related rework costs

Safety incidents: 25% of workplace injuries involve tool-related accidents

Strategic Tool Storage Solution Implementation

1. Manufacturing Process Analysis and Tool Mapping

Comprehensive Workflow Assessment

Before implementing tool storage solutions, conduct a thorough manufacturing process analysis:

Production Zone Classification

Raw material processing: Tools for cutting, shaping, and initial material preparation

Assembly operations: Equipment for component assembly and sub-assembly production

Quality control stations: Tools for inspection, measurement, and testing procedures

Packaging and finishing: Equipment for final product preparation and shipping

Maintenance areas: Tools for equipment upkeep, repair, and facility maintenance

Tool Usage Pattern Analysis

| Manufacturing Stage | Tool Requirements | Usage Frequency | Storage Priority |

|---|---|---|---|

| Material Processing | Cutting tools, measuring devices | Continuous | Critical |

| Assembly Operations | Hand tools, power equipment | High | High |

| Quality Control | Precision instruments, gauges | Regular | Critical |

| Packaging | Sealing tools, labeling equipment | Moderate | Medium |

| Maintenance | Repair kits, diagnostic tools | As needed | Variable |

2. Advanced Tool Storage System Design

Multi-Drawer Configuration Strategy

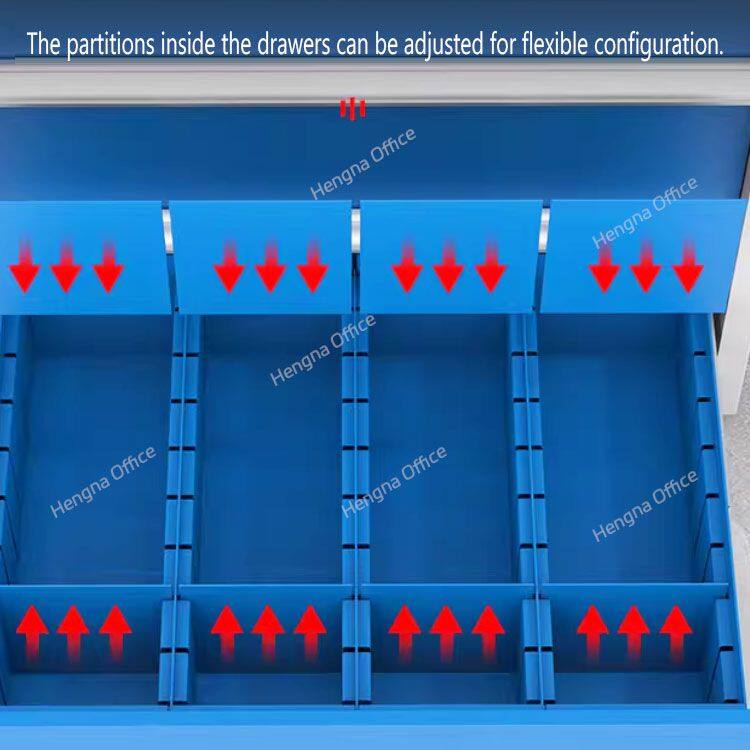

Based on the reference images showing versatile drawer systems, manufacturing tool storage should feature:

Optimal Drawer Organization

Five-drawer systems: Comprehensive categorization accommodating diverse manufacturing tools

Progressive depth configuration: Shallow top drawers (2-3 inches) for small items, deeper bottom drawers (8-12 inches) for bulky equipment

Weight distribution engineering: Heavy tools strategically placed in bottom drawers for stability and safety

Customizable compartment systems: Adjustable dividers adapting to changing manufacturing requirements

Manufacturing-Specific Storage Features

Heavy-duty construction: Steel frames supporting 500-800 lbs of manufacturing tools

Enhanced mobility: Industrial-grade casters navigating manufacturing floor environments

Security integration: Locking systems protecting valuable manufacturing equipment

Environmental protection: Sealed compartments protecting tools from manufacturing contaminants

3. Zone-Specific Tool Storage Solutions

Production Line Integration

Assembly Line Tool Stations

Line-side positioning: Mobile tool carts positioned within arm’s reach of assembly stations

Sequential tool organization: Tools arranged following assembly sequence for optimal efficiency

Quick-change capabilities: Rapid tool swapping supporting product changeovers

Standardized configurations: Consistent setup across multiple assembly lines

Quality Control Areas

Precision tool storage: Specialized compartments for sensitive measuring and testing equipment

Calibration management: Integrated systems tracking tool calibration schedules and status

Clean storage environments: Protected compartments preventing contamination of precision instruments

Documentation integration: Storage for quality control records and testing documentation

Manufacturing Process Optimization Strategies

1. Lean Manufacturing Tool Management

5S Implementation for Tool Storage

Sort (Seiri)

Tool categorization: Systematic organization eliminating unnecessary tools from work areas

Frequency-based placement: Most frequently used tools positioned for immediate access

Redundancy elimination: Removal of duplicate tools and unnecessary equipment

Standardization creation: Consistent tool organization across all manufacturing areas

Set in Order (Seiton)

Designated locations: Specific storage positions for each tool category

Visual management: Clear labeling and color-coding systems for easy identification

Accessibility optimization: Tool placement minimizing movement and search time

Ergonomic arrangement: Tool positioning reducing physical strain and fatigue

Shine (Seiso)

Regular cleaning schedules: Systematic tool and storage maintenance procedures

Inspection integration: Tool condition checking during cleaning processes

Preventive maintenance: Scheduled tool servicing and replacement programs

Continuous improvement: Ongoing optimization of cleaning and maintenance processes

Standardize (Seiketsu)

Consistent procedures: Standardized tool storage and handling protocols

Training programs: Comprehensive education on proper tool management

Documentation systems: Written procedures and visual guides for tool storage

Performance monitoring: Regular audits and compliance checking

Sustain (Shitsuke)

Accountability systems: Individual responsibility for tool storage maintenance

Continuous training: Ongoing education and reinforcement of proper procedures

Performance recognition: Rewards and recognition for tool storage excellence

Regular audits: Scheduled reviews and improvement opportunities

2. Just-in-Time Tool Delivery Systems

Mobile Tool Cart Networks

Automated delivery: Scheduled tool cart movement to production areas as needed

Demand-based positioning: Tool placement based on production schedules and requirements

Real-time availability: Systems showing current tool location and availability status

Quick response capabilities: Rapid tool delivery for urgent production needs

Tool Inventory Management

Real-time tracking: Continuous monitoring of tool location, usage, and condition

Automated reordering: Systems triggering tool replacement when inventory reaches minimum levels

Usage analytics: Data analysis optimizing tool inventory levels and placement

Cost tracking: Detailed monitoring of tool acquisition, maintenance, and replacement costs

Technology Integration for Manufacturing Excellence

1. Smart Tool Storage Systems

IoT-Enabled Manufacturing Solutions

Sensor integration: Tool carts equipped with weight, proximity, and usage sensors

Real-time monitoring: Continuous tracking of tool location, availability, and condition

Predictive maintenance: AI algorithms forecasting tool maintenance needs and replacement timing

Automated alerts: Notifications for tool maintenance, calibration, or replacement requirements

Manufacturing Execution System (MES) Integration

Production scheduling: Tool availability integrated with manufacturing planning systems

Quality control linkage: Tool condition monitoring affecting quality assurance processes

Inventory synchronization: Real-time tool inventory updates across manufacturing systems

Performance analytics: Comprehensive reporting on tool utilization and efficiency impacts

2. Digital Twin Technology

Virtual Tool Management

Digital modeling: Virtual representations of physical tool storage systems

Simulation capabilities: Testing different tool organization strategies before implementation

Optimization algorithms: AI-powered systems suggesting optimal tool placement and organization

Predictive analysis: Forecasting tool needs based on production schedules and requirements

Measuring Manufacturing Process Improvement

Key Performance Indicators (KPIs)

Efficiency Metrics

| Performance Indicator | Before Implementation | After Implementation | Improvement |

|---|---|---|---|

| Tool Search Time | 10-15 minutes per task | 1-2 minutes per task | 85% reduction |

| Production Downtime | 4.5 hours per week | 1.5 hours per week | 67% reduction |

Changeover Time | 45 minutes | 25 minutes | 44% reduction |

Overall Equipment Effectiveness (OEE) | 72% | 85% | 18% increase |

Quality Improvements

Defect reduction: 25-35% decrease in tool-related quality issues

Rework costs: 40-50% reduction in rework expenses

Customer satisfaction: 15-20% improvement in quality-related customer satisfaction

Compliance rates: 95%+ achievement of quality standards and specifications

Financial Impact Analysis

Revenue Enhancement

Increased production capacity: 20-30% improvement in daily output volume

Reduced changeover time: 40-50% faster product changeovers increasing flexibility

Improved quality: Higher first-pass yield reducing scrap and rework costs

Enhanced customer satisfaction: Improved on-time delivery and quality performance

Cost Reduction Benefits

Labor efficiency: 25-35% improvement in worker productivity

Tool management costs: 50-60% reduction in tool replacement and maintenance expenses

Quality cost savings: 30-40% reduction in quality-related expenses

Safety improvements: 60-70% reduction in tool-related workplace incidents

Implementation Best Practices

1. Phased Implementation Strategy

Pilot Program Approach

Area selection: Choose one manufacturing area for initial implementation

Baseline measurement: Document current performance metrics and tool management challenges

Solution implementation: Deploy tool storage systems in pilot area

Results evaluation: Measure improvements and identify optimization opportunities

Full-Scale Rollout

Learnings application: Apply pilot program insights to facility-wide implementation

Training reinforcement: Comprehensive education for all manufacturing personnel

System integration: Ensure compatibility with existing manufacturing systems

Continuous improvement: Ongoing optimization based on performance data

2. Change Management Excellence

Employee Engagement Strategies

Stakeholder involvement: Include manufacturing employees in selection and design processes

Benefits communication: Clear explanation of improvements and advantages

Training programs: Comprehensive education on new tool storage systems

Feedback mechanisms: Regular input collection and system refinement

Tags: Streamlining Your Manufacturing Process, Right Tool Storage Solutions, Tool Storage