What Should I Check Before Choosing a Heavy-Duty Steel Shelving Manufacturer from China?

In today’s globalized marketplace, China has emerged as the world’s leading manufacturer of industrial shelving solutions. However, selecting the right heavy-duty steel shelving manufacturer requires careful consideration and thorough evaluation. This comprehensive guide will walk you through the essential factors to consider when choosing a Chinese manufacturer for your industrial storage needs, ensuring you make an informed decision that guarantees quality, reliability, and long-term value.

Manufacturing Excellence and Quality Standards

Material Quality and Thickness

When evaluating potential manufacturers, material quality should be your primary consideration. Look for suppliers who utilize thickened adjustable laminates that provide superior durability and extended service life. High-quality steel should feature:

Premium cold-rolled steel construction with consistent thickness

Anti-corrosion coating for enhanced longevity

Weight-bearing capacity that meets international standards

Surface finish quality that resists scratches and wear

Welding and Structural Integrity

The welding quality directly impacts the safety and durability of your shelving systems. Professional manufacturers employ advanced welding techniques that ensure:

Full material penetration for maximum strength

Consistent weld beads without cracks or porosity

Reinforced stress points at critical junctions

Quality control inspections at every production stage

Key Insight: At Luoyang Hengna Office Furniture Co., Ltd., our professional welding processes ensure full material penetration and superior structural integrity, setting the industry standard for heavy-duty shelving manufacturing.

Design Engineering and Technical Specifications

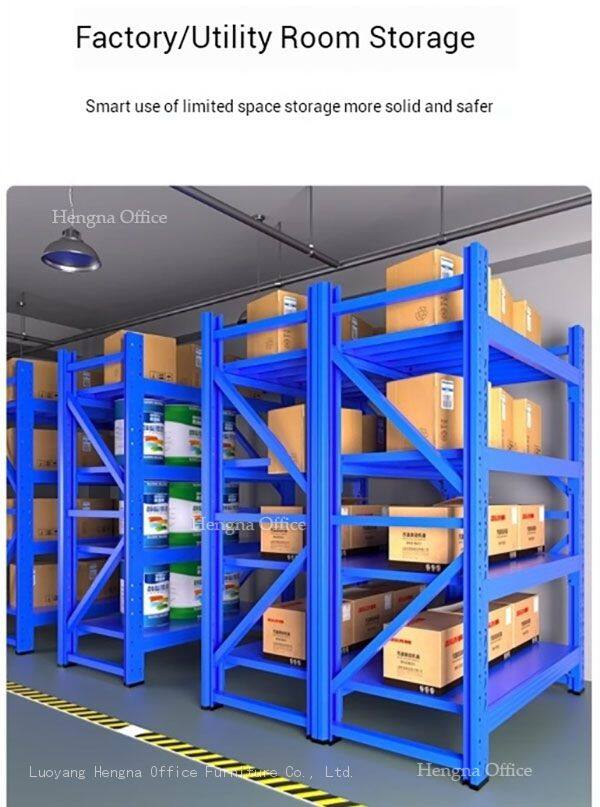

Scientific Structural Design

Modern heavy-duty shelving should incorporate scientific design principles that optimize stability and load distribution. Look for manufacturers who implement:

Triangular column designs with horizontal and diagonal supports

Engineering calculations based on load requirements

Finite element analysis for stress distribution

Safety factor incorporation exceeding industry standards

Customization Capabilities

A reliable manufacturer should offer extensive customization options to meet your specific requirements:

| Customization Feature | Importance Level | What to Look For |

|---|---|---|

| Dimensional flexibility | High | Custom length, width, height options |

| Load capacity variations | High | Multiple weight-bearing configurations |

| Color choices | Medium | Blue, off-white, and custom color options |

| Tier configurations | Medium | 3-6 tier options with adjustability |

Production Capacity and Manufacturing Facilities

Advanced Production Equipment

When selecting a Chinese manufacturer, evaluate their production capabilities:

Automated cutting systems for precision manufacturing

Robotic welding stations for consistent quality

Powder coating facilities for durable finishes

Quality testing laboratories for product validation

Production Scale and Lead Times

Consider the manufacturer’s production capacity to ensure they can meet your requirements:

Monthly production volume capabilities

Order fulfillment timelines

Inventory management systems

Supply chain reliability

Safety and Environmental Compliance

Ensure your chosen manufacturer adheres to strict safety standards:

Workplace safety protocols

Environmental protection measures

Sustainable manufacturing practices

Waste management systems

Technical Support and After-Sales Service

Engineering Support Services

A reliable manufacturer provides comprehensive technical support:

Design consultation for optimal space utilization

Installation guidance and technical documentation

Load calculation assistance for complex applications

Maintenance recommendations for extended lifespan

Warranty and Quality Assurance

Evaluate the warranty terms and quality guarantees:

Structural warranty coverage (typically 5-10 years)

Finish warranty protection against corrosion

Replacement policies for defective components

Quality assurance procedures throughout production

Price Evaluation and Total Cost of Ownership

Competitive Pricing Analysis

While cost considerations are important, focus on total value proposition:

Unit price comparisons across multiple manufacturers

Volume discount opportunities

Shipping and logistics costs

Import duties and taxes

Long-Term Value Assessment

Consider the total cost of ownership rather than initial purchase price:

Durability and lifespan expectations

Maintenance requirements and associated costs

Replacement frequency and downtime impact

Operational efficiency improvements

Communication and Business Practices

Language and Cultural Considerations

Effective communication channels are essential for successful partnerships:

English-speaking representatives for technical discussions

Cultural understanding of international business practices

Response time expectations for inquiries and issues

Documentation clarity for specifications and requirements

Business Reputation and Track Record

Research the manufacturer’s industry reputation:

Customer testimonials and case studies

Industry experience and years in operation

Export market presence and global partnerships

Financial stability and business longevity

Red Flags to Avoid

Warning Signs During Supplier Evaluation

Be cautious of manufacturers exhibiting these concerning indicators:

Reluctance to provide detailed product specifications

Limited quality control documentation

Unrealistically low pricing compared to market standards

Poor communication response times

Lack of proper certifications or compliance documentation

Due Diligence Best Practices

Implement thorough verification processes:

Factory audits either in-person or virtual

Third-party quality inspections before shipment

Sample testing for quality verification

Reference checks with existing customers

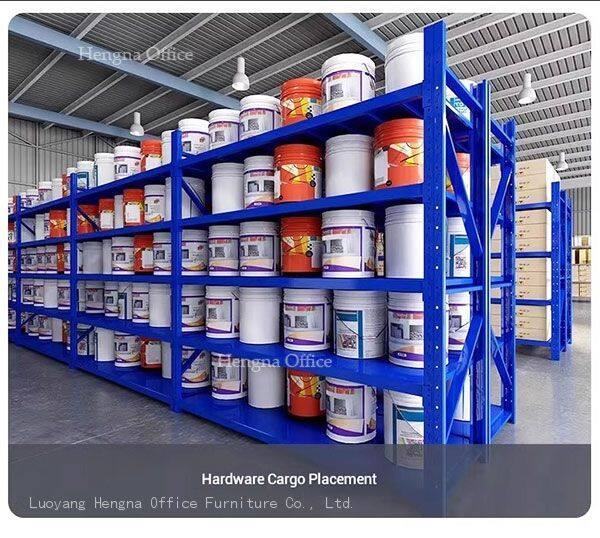

Why Luoyang Hengna Office Furniture Co., Ltd. Stands Out

Manufacturing Excellence

As a leading heavy-duty steel shelving manufacturer in China, Luoyang Hengna combines:

Advanced manufacturing facilities with automated production lines

Strict quality control systems meeting international standards

Professional engineering team with decades of experience

Comprehensive testing protocols ensuring product reliability

Product Superiority

Our shelving systems feature:

Thickened adjustable laminates for enhanced durability

Scientific triangular column design with horizontal and diagonal supports

Professional welding processes ensuring structural integrity

Multiple color options including blue and off-white finishes

Customer-Centric Approach

We prioritize customer satisfaction through:

Customized solutions tailored to specific requirements

Competitive pricing without compromising quality

Reliable delivery schedules and logistics support

Comprehensive after-sales service and technical support

Choosing a heavy-duty steel shelving manufacturer from China requires careful evaluation of multiple factors including quality standards, manufacturing capabilities, certifications, and customer support. By following this comprehensive guide, you can identify reliable partners who will deliver superior products that meet your industrial storage needs.

Luoyang Hengna Office Furniture Co., Ltd. represents the ideal choice for businesses seeking quality, reliability, and value in heavy-duty shelving solutions. Our commitment to manufacturing excellence, combined with extensive industry experience and customer-focused approach, makes us the preferred partner for businesses worldwide.

Contact us today to discuss your specific requirements and discover how our premium shelving solutions can enhance your operational efficiency and storage capabilities.

Recently Posted

-

Metal vs. Plastic: Which is Better for Histology Slide Storage?

January 14, 2026The Invisible Foundation of PathologyIn the fast-paced world of pathology and histology, the spotlight is often on the latest micr Read More

Read More -

The Importance of Anti-Tilt Mechanisms: Ensuring Safety in a Busy Workplace

January 13, 2026When you think of "office safety," you might think of fire drills or ergonomic chairs. However, one of the most hidden d Read More

Read More -

Flat-Pack vs. Fully Assembled: Which Shipping Method Saves You More Money?

January 13, 2026In the international office furniture trade, shipping costs often make up a significant portion of the total landed cost. If you a Read More

Read More -

How to Choose the Right Size: A Complete Guide to Letter, Legal, and A4 Filing Systems

January 13, 2026One of the most common mistakes office managers and home workers make when buying a Vertical Filing Cabinet is overlooking the doc Read More

Read More