Starter vs. Add-on: How to Design and Save Money on Large Warehouse Shelving Projects

The Blueprint for Profit: Mastering Modular Design for Warehouse Shelving

1. The Strategic Difference in Large-Scale Procurement

For warehouse managers, contractors, and bulk importers planning large-scale storage installations, the initial material cost is only part of the equation. Significant, long-term savings are hidden within the structure itself. The most critical decision is mastering the Starter vs. Add-on Bay principle. Understanding this modular design is the key to achieving optimal High Density Warehouse Shelving layouts while drastically reducing material consumption and project costs.

2. Defining the Modular Advantage

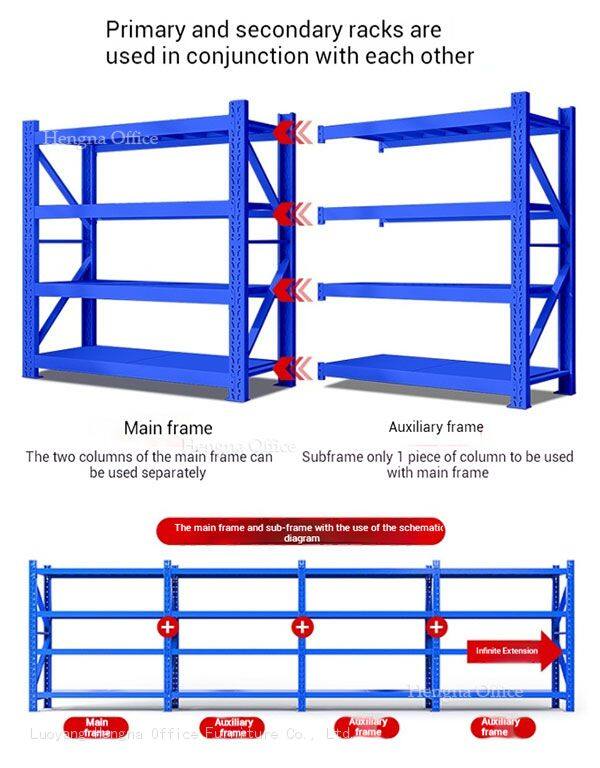

Our Cold Rolled Steel racking systems are built around two components: the Main Frame (Starter Bay) and the Auxiliary Frame (Add-on Bay).

| Component | Description | Structural Role | Cost Benefit |

| Starter Bay (Main Frame) | The initial, standalone unit. Includes two full upright columns. | Required to start any row of shelving. | Provides structural independence. |

| Add-on Bay (Auxiliary Frame) | The extension unit. Includes shelving but only one upright column. | Shares the column of the preceding Starter or Add-on Bay. | Saves the cost of one entire column per unit. |

3. The Math Behind the Savings

Using the Starter/Add-on method allows for infinite extension of your shelving runs. Let's compare the cost of a continuous 10-meter run composed of ten 1-meter bays:

10 Individual Units: Requires 20 upright columns.

Modular System: 1 Starter Bay (2 columns) + 9 Add-on Bays (9 columns) = 11 total columns.

By using this design, you achieve the same High-Capacity Metal Stacks footprint but reduce the number of expensive upright columns needed by nearly 50%. This material saving directly translates into higher profit margins for the importer and lower project costs for the end-user.

4. Design Flexibility for Warehouse Optimization

This modular approach doesn't sacrifice performance; it enhances it by providing flexibility crucial for dynamic warehouse environments:

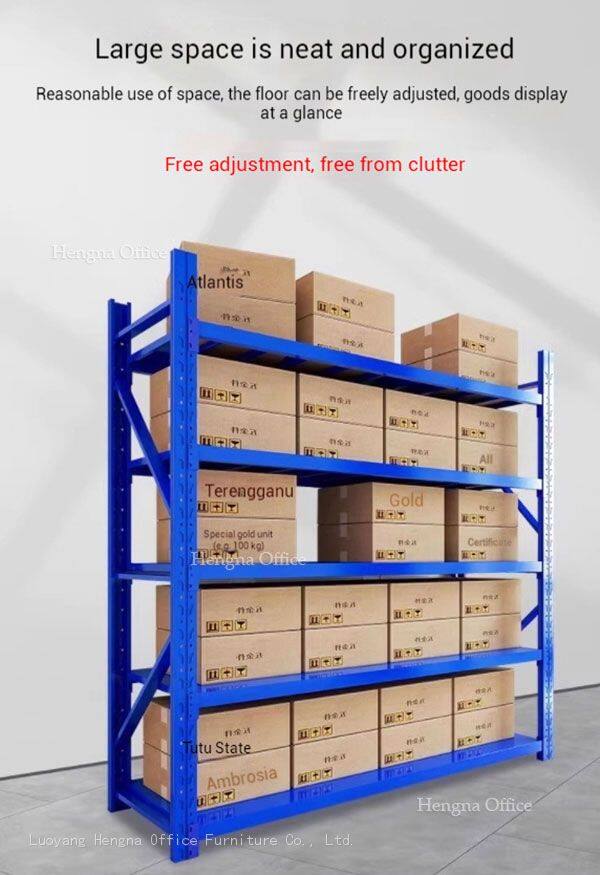

Free Splicing Combination: Allows for custom-length rows that fit perfectly against walls or run the full length of a warehouse aisle.

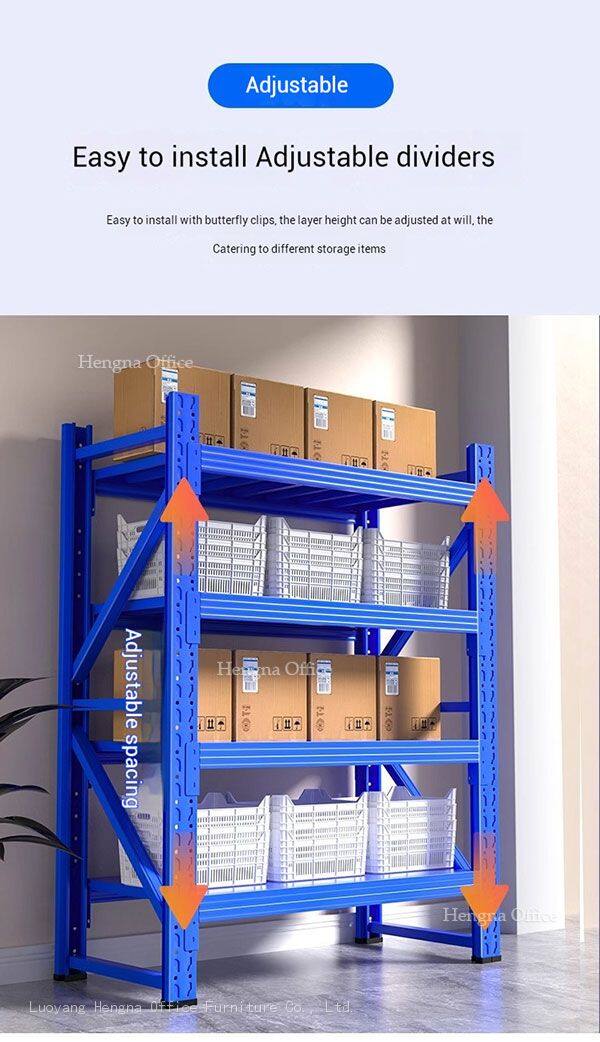

Adjustable Flexibility: The system features Adjustable Laminates (shelves). The Height is free lift mounting, allowing operators to adjust the shelf height at will to match different sizes of objects or specific inventory needs.

Structural Integrity: Even in an infinite extension model, the structure maintains exceptional stability thanks to the use of thickened columns and Reinforcement welding and Triangular mechanical support.

5. Quick Assembly and Quality Assurance

To ensure fast deployment of large projects, our modular system utilizes an efficient assembly method:

Tool-Free Buckle Design: The system uses a Buckle Design for convenient insertion and disassembly, allowing for easy installation without a single screw. This "snap-on design" cuts down on the installation labor associated with large-scale fit-outs.

Durable Finish: All components feature a Multi-layer protection against rust and an Electrostatic spraying finish, ensuring the Cold Rolled Steel Shelf maintains its structural integrity and appearance over a long service life.

6. Conclusion: The Strategic Choice for Large Projects

Mastering the Starter vs. Add-on design is the single most effective strategy for Saving Money on Large Warehouse Shelving Projects. It is an intelligent procurement decision that optimizes material use, maximizes freight space, and ensures your High Density layout is both scalable and structurally sound

Recently Posted

-

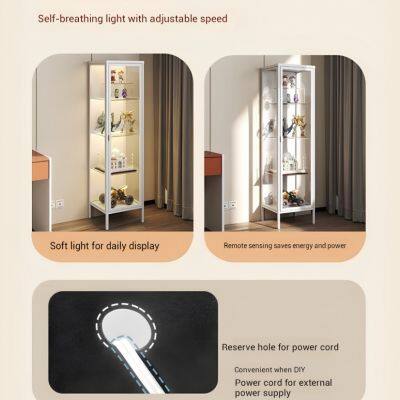

First Sight at the Entryway: How Sensor-Lit Display Cabinets Define Your Home’s Style

January 8, 2026They say you never get a second chance to make a first impression. In the world of interior design, the entryway (foyer) is the &q Read More

Read More -

Farewell to "Spider Webs": How Hidden Cable Management Holes Elevate Your Display Cabinet's Premium

January 8, 2026In the world of high-end collecting and retail display, there is a silent enemy that ruins even the most expensive setups: The Spi Read More

Read More -

How to Design a Safe and Sanitary Nursing Room in Public Spaces?

January 8, 2026The Business Case for Family-Friendly SpacesIn the modern commercial landscape, the quality of a facility is often judged by its m Read More

Read More -

Fingerprint Lock Failure? 3 Key Factors to Improve Recognition Rates Avoid Procurement Pitfalls

January 8, 2026When buying electronic storage lockers, many worry: will the fingerprint lock really work reliably? From budget models f Read More

Read More