Choose the Best Heavy Workbench for Automotive Repair and Maintenance

Automotive repair and maintenance operations demand workbenches that can withstand the unique challenges of vehicle service environments. From heavy engine components to chemical exposure and constant tool use, automotive workbenches must provide exceptional durability, functionality, and organization. This comprehensive guide explores the essential features and considerations for selecting heavy workbenches specifically designed for automotive applications.

Understanding Automotive Workshop Requirements

Automotive workshops present demanding environments that test the limits of standard workbenches. The need to support heavy engine blocks, transmissions, and suspension components requires substantial weight capacity and structural integrity. Additionally, automotive work involves exposure to oils, fuels, cleaning chemicals, and temperature variations that can rapidly degrade lesser-quality workbenches.

Professional automotive technicians require workbenches that facilitate efficient workflow while maintaining organization and accessibility. The ability to securely hold components during disassembly and reassembly processes directly impacts repair quality and efficiency. Surface materials must resist chemical damage while providing suitable work areas for both delicate electronic components and heavy mechanical parts.

Weight Capacity and Construction Standards

Automotive workbenches must support substantial loads, with quality models typically rated for 1000-2000 pounds distributed across the surface. Engine blocks alone can weigh 300-600 pounds, while transmissions and differential assemblies add additional weight requirements. The workbench must maintain stability under these loads without wobbling or deflection that could compromise precision work.

Construction quality directly impacts weight capacity and longevity. Heavy-gauge steel frames, typically 12-14 gauge thickness, provide the necessary strength and rigidity. Reinforced leg construction and cross-bracing prevent racking under heavy loads. Professional automotive workbenches often feature welded construction rather than bolted connections for enhanced strength and durability.

Chemical Resistance and Surface Durability

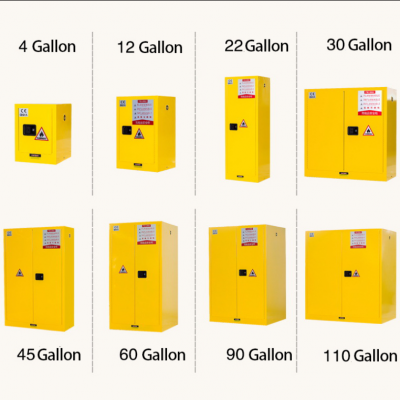

Automotive work involves constant exposure to various chemicals that can damage workbench surfaces. Motor oils, transmission fluids, brake cleaners, and solvents can rapidly degrade unprotected materials. Quality automotive workbenches incorporate chemical-resistant surfaces that withstand these exposures while maintaining functionality and appearance.

Stainless steel surfaces offer excellent chemical resistance and durability for automotive applications. Powder-coated steel provides protection against corrosion and chemical damage while offering various color options. Some workbenches feature specialized polymer or composite surfaces designed specifically for automotive environments. The choice depends on specific chemical exposure levels and cleaning protocols.

Storage and Organization Features

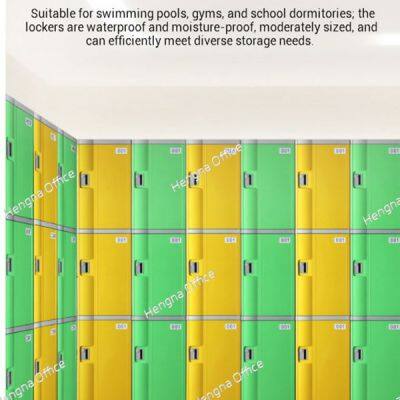

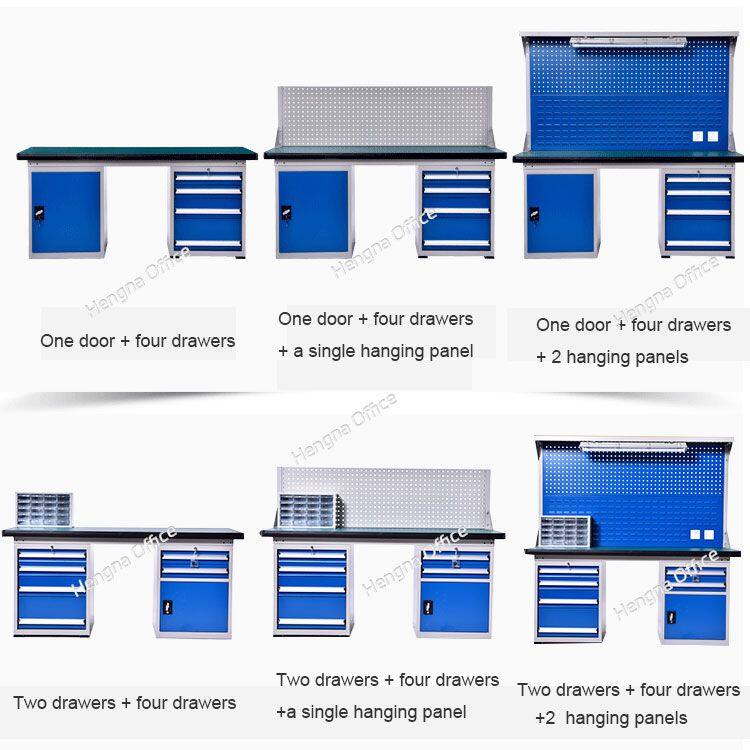

Automotive technicians require extensive tool and parts organization to maintain efficient workflow. Heavy workbenches designed for automotive applications incorporate various storage solutions including drawers, cabinets, and shelving systems. Drawer capacity must support heavy tool sets, with quality slides rated for 100-200 pounds per drawer.

Integrated locking systems provide security for valuable tools and equipment. Pegboard backing or tool panel systems allow for customizable tool organization and easy access. Some automotive workbenches feature specialized storage for oil filters, fluids, and commonly used parts. These organization features directly impact technician productivity and workspace efficiency.

Ergonomics and Technician Comfort

Automotive technicians often spend extended periods at their workbenches, making ergonomics crucial for preventing fatigue and injury. Standard automotive workbench height typically ranges from 36-40 inches, accommodating both standing and seated work positions. Some models offer height adjustability to accommodate different technicians and various tasks.

Anti-fatigue matting around workbench areas reduces physical stress during extended standing periods. Proper lighting integration prevents eye strain during detailed work. Consideration of workflow patterns influences workbench design, with placement of storage and work areas optimized for common automotive repair procedures. These ergonomic considerations enhance technician comfort and productivity.

Specialized Features for Automotive Applications

Automotive workbenches often incorporate specialized features designed specifically for vehicle repair operations. Integrated vise systems with pipe jaws securely hold round components like exhaust pipes and drive shafts. Built-in measuring systems and straight edges facilitate precision measurements during component inspection and repair.

Some automotive workbenches feature integrated fluid drainage systems for cleanup after oil changes or fluid services. Power strip mounting with GFCI protection provides safe electrical access for tools and diagnostic equipment. Specialized mounting points for brake lathes, wheel balancers, or other automotive equipment enhance versatility and functionality.

Mobility and Flexibility Options

While many automotive workbenches remain stationary, mobile options provide flexibility for workshop layout changes and specific repair scenarios. Heavy-duty casters with locking mechanisms allow workbench repositioning while maintaining stability when stationary. Mobile workbenches facilitate vehicle access and workspace reconfiguration as needed.

Some automotive workshops utilize modular workbench systems that can be reconfigured as service needs change. The ability to add or remove components, adjust heights, or connect multiple units creates versatile workspaces that adapt to evolving requirements. This flexibility ensures long-term utility and value for automotive operations.

Safety Considerations and Compliance

Automotive workbench safety requires attention to several critical factors. Weight capacity ratings must be clearly marked and never exceeded to prevent collapse and injury. Rounded corners and edges reduce injury risk during busy workshop operations. Integrated safety features including non-slip surfaces and secure drawer locking mechanisms prevent accidents.

Compliance with OSHA standards and local building codes ensures safe operation in commercial automotive facilities. Proper anchoring to floors prevents tipping, especially important for tall or heavily loaded workbenches. Regular inspection and maintenance of all components ensures continued safe operation throughout the workbench service life.

Investment Value and ROI Considerations

Quality automotive workbenches represent significant investments that directly impact technician productivity and repair quality. While initial costs may be substantial, the long-term benefits include improved efficiency, reduced tool replacement costs, and enhanced technician satisfaction. Professional-grade workbenches typically provide 15-20 years of service with proper maintenance.

ROI calculations should consider both direct financial benefits and indirect advantages such as improved repair quality and customer satisfaction. The ability to securely support heavy components prevents damage that could result in costly repairs or replacements. Enhanced organization reduces time spent searching for tools and parts, directly impacting technician productivity and shop profitability.

Maintenance and Care Requirements

Automotive workbench maintenance ensures longevity and continued performance. Regular cleaning removes chemical residues that could degrade surfaces over time. Lubrication of drawer slides and moving parts prevents binding and extends component life. Periodic inspection of welds, fasteners, and structural components identifies potential issues before they become serious problems.

Surface maintenance varies by material type but typically involves cleaning with appropriate automotive-grade cleaners. Stainless steel surfaces may require periodic polishing to maintain appearance and corrosion resistance. Wood surfaces need regular oiling or sealing to prevent damage from automotive fluids. These maintenance practices protect the investment and ensure reliable performance.

Selecting the right heavy workbench for automotive repair and maintenance requires careful consideration of weight capacity, chemical resistance, storage needs, and specialized features. By understanding these requirements and evaluating options based on specific automotive applications, shop owners and technicians can choose workbenches that enhance productivity, ensure safety, and provide long-term value. The right automotive workbench becomes an essential partner in delivering quality vehicle service and maintaining professional workshop operations.

Selecting the right heavy workbench for automotive repair and maintenance requires careful consideration of weight capacity, chemical resistance, storage needs, and specialized features. By understanding these requirements and evaluating options based on specific automotive applications, shop owners and technicians can choose workbenches that enhance productivity, ensure safety, and provide long-term value. The right automotive workbench becomes an essential partner in delivering quality vehicle service and maintaining professional workshop operations.

Recently Posted

-

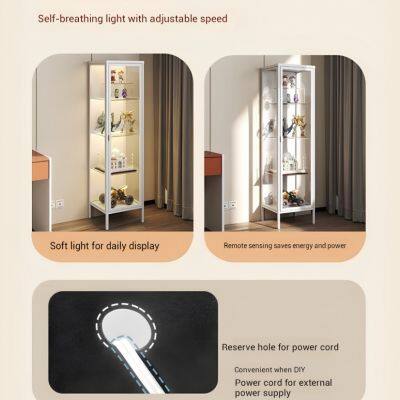

First Sight at the Entryway: How Sensor-Lit Display Cabinets Define Your Home’s Style

January 8, 2026They say you never get a second chance to make a first impression. In the world of interior design, the entryway (foyer) is the &q Read More

Read More -

Farewell to "Spider Webs": How Hidden Cable Management Holes Elevate Your Display Cabinet's Premium

January 8, 2026In the world of high-end collecting and retail display, there is a silent enemy that ruins even the most expensive setups: The Spi Read More

Read More -

Safety Beyond the Lock: Why 3C Tempered Glass, Rounded Corners, and Anti-Tip Kits Are Non-Negotiable

January 8, 2026When we think about "securing" a display cabinet, our minds immediately go to the lock. We think about protecting the co Read More

Read More -

How to Design a Safe and Sanitary Nursing Room in Public Spaces?

January 8, 2026The Business Case for Family-Friendly SpacesIn the modern commercial landscape, the quality of a facility is often judged by its m Read More

Read More