-

Sarah

Hi there! Welcome to my shop. Let me know if you have any questions.

Sarah

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

Welding-Ready Heavy Workbenches: Essential Features for Metal Fabrication

2025-11-03 13:37:06

Metal fabrication and welding operations demand workbenches that can withstand extreme conditions including intense heat, sparks, heavy metal loads, and constant hammering. Standard workbenches quickly fail under these demanding conditions, making specialized welding-ready workbenches essential for professional metalworking operations. This comprehensive guide explores the critical features and considerations for selecting heavy workbenches specifically designed for welding and metal fabrication applications.

Understanding Welding Workshop Requirements

Welding and metal fabrication present unique challenges that require specialized workbench solutions. The combination of intense heat from welding torches, heavy metal components, and physical forces from hammering and forming demands exceptional durability and heat resistance. Additionally, metal fabrication involves various chemicals, grinding debris, and potential fire hazards that must be addressed in workbench design.

Professional welders and metal fabricators require workbenches that provide stable platforms for precise work while withstanding the harsh conditions of metalworking operations. The ability to securely hold workpieces during welding, resist heat damage, and maintain organization for tools and materials directly impacts work quality and safety. These specialized requirements distinguish welding workbenches from general-purpose workstations.

Heat Resistance and Fire Safety Features

Heat resistance represents the most critical requirement for welding workbenches. Welding temperatures can exceed 10,000°F at the weld point, with significant heat transfer to work surfaces. Quality welding workbenches incorporate materials and designs that withstand these temperatures without warping, burning, or releasing toxic fumes.

Steel construction provides superior heat resistance compared to wood or composite materials. Thick steel plate surfaces, typically 1/4 to 1/2 inch thick, dissipate heat effectively and resist burn-through. Some welding workbenches incorporate fire-resistant coatings or specialized heat-dissipating designs. Fire safety features including spark-resistant construction and non-combustible materials prevent workshop fires and ensure safe operation.

Weight Capacity and Structural Integrity

Metal fabrication often involves heavy steel components, thick plates, and assembled structures that require substantial support capacity. Professional welding workbenches typically support 1000-3000 pounds distributed across the surface, with some industrial models exceeding 5000 pounds capacity. This capacity must be maintained without deflection that could compromise weld quality or safety.

Structural integrity derives from heavy-duty construction methods and materials. Heavy-gauge steel frames, typically 10-12 gauge thickness, provide the necessary strength and rigidity. Reinforced leg construction with diagonal bracing prevents racking under heavy loads and hammering forces. Welded construction rather than bolted connections enhances strength and eliminates potential failure points under stress.

Surface Materials and Welding Performance

Workbench surfaces directly impact welding quality and efficiency. Steel plate surfaces provide ideal grounding for welding equipment and resist heat damage during welding operations. Some welding workbenches feature specialized surfaces including copper alloys for heat dissipation or cast iron surfaces for smooth workpiece movement.

Surface preparation options enhance welding performance. Some workbenches incorporate built-in clamping systems with heat-resistant components. Others feature modular surface plates that can be replaced when damaged. The choice depends on specific welding processes, material types, and workpiece requirements. Surface quality directly affects weld quality and workpiece handling efficiency.

Ventilation and Fume Extraction Integration

Welding produces hazardous fumes and particulate matter that must be managed for worker safety. Professional welding workbenches often integrate with ventilation and fume extraction systems to protect welder health and maintain air quality. Built-in downdraft tables or backdraft extraction systems capture fumes at the source before they can spread throughout the workshop.

Some welding workbenches feature adjustable ventilation ports that can be positioned based on workpiece size and welding position. Others incorporate connections for portable fume extractors or centralized ventilation systems. Proper ventilation integration not only protects worker health but also improves visibility during welding operations by removing smoke and particulate matter.

Tool Storage and Organization Systems

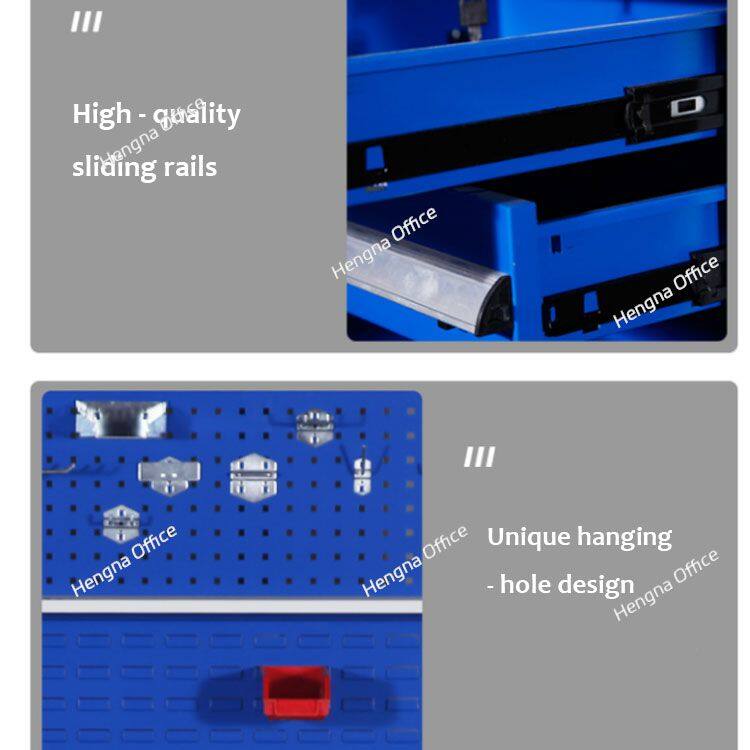

Metal fabrication requires extensive tool and equipment organization to maintain efficient workflow. Heavy welding workbenches incorporate various storage solutions including drawers, cabinets, and shelving systems designed specifically for welding tools and accessories. Drawer capacity must support heavy welding equipment, with quality slides rated for 150-250 pounds per drawer.

Specialized storage features include welding rod holders, gas cylinder storage compartments, and grinding wheel storage. Some workbenches feature integrated welding helmet storage and fire-resistant storage for flammable materials. Tool organization systems with customizable layouts accommodate different welding processes and personal preferences, enhancing efficiency and reducing time spent searching for equipment.

Electrical Safety and Grounding Considerations

Welding equipment requires proper electrical grounding and safety considerations to prevent shock hazards and ensure equipment performance. Professional welding workbenches often incorporate built-in grounding systems that provide secure electrical connections for welding equipment. Integrated power strips with appropriate circuit protection provide safe electrical access for welding machines and tools.

Some welding workbenches feature isolated grounding systems to prevent electrical interference with sensitive welding processes. Others incorporate built-in cable management systems to keep electrical cables organized and prevent trip hazards. These electrical safety features protect both equipment and operators while ensuring consistent welding performance.

Mobility and Workspace Flexibility

While many welding workbenches remain stationary, mobile options provide flexibility for workshop layout changes and specific fabrication projects. Heavy-duty casters with locking mechanisms allow workbench repositioning while maintaining stability during welding operations. Mobile workbenches facilitate positioning for large workpieces or collaborative welding projects.

Some metal fabrication operations utilize modular workbench systems that can be reconfigured as project needs change. The ability to connect multiple units, adjust heights, or add specialized components creates versatile workspaces that adapt to evolving fabrication requirements. This flexibility ensures long-term utility and value for metalworking operations.

Safety Features and Compliance

Welding safety requires comprehensive protection strategies, and workbenches play crucial roles in overall safety programs. Spark-resistant construction prevents ignition of surrounding materials. Built-in fire extinguisher mounting ensures quick access during emergencies. Rounded corners and edges reduce injury risk during busy fabrication operations.

Compliance with OSHA standards and local building codes ensures safe operation in commercial metal fabrication facilities. Proper anchoring prevents tipping, especially important for tall or heavily loaded workbenches. Regular inspection of all components ensures continued safe operation throughout the workbench service life. Some welding workbenches incorporate built-in safety screens or curtains to protect against UV radiation and sparks.

Maintenance and Durability Considerations

Welding workbenches operate in harsh environments that require regular maintenance to ensure longevity and performance. Surface inspection and replacement prevents weld-through and maintains work quality. Hardware inspection and tightening prevents loose components that could compromise stability. Cleaning removes welding spatter and debris that could affect performance.

Quality construction materials resist corrosion and degradation from welding processes. Stainless steel components provide excellent durability in welding environments. Replaceable surface plates extend workbench life when damage occurs. These maintenance and durability features ensure reliable performance and protect the investment in professional welding equipment.

Selecting welding-ready heavy workbenches requires careful consideration of heat resistance, weight capacity, safety features, and specialized welding requirements. By understanding these critical factors and evaluating options based on specific metal fabrication applications, welders and fabricators can choose workbenches that enhance work quality, ensure safety, and provide long-term value. The right welding workbench becomes an essential partner in metal fabrication operations, supporting professional craftsmanship and workshop safety.

Tags: Heavy Workbench, Welding-Ready Heavy Workbenches, Metal Fabrication