-

Sarah

Hi there! Welcome to my shop. Let me know if you have any questions.

Sarah

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

How to Improve Tool Organization in Your Warehouse with Rolling Tool Carts

2025-10-28 17:05:04

Transforming Warehouse Tool Management Efficiency

In today’s competitive logistics landscape, effective warehouse tool organization has become a critical factor in operational success. Warehouse managers face daily challenges in maintaining tool accessibility, accountability, and efficiency across vast storage facilities. Rolling tool carts represent a strategic solution that revolutionizes how warehouses manage their tool inventory, streamline workflows, and enhance overall productivity. This comprehensive guide explores proven strategies to optimize your warehouse tool organization using mobile storage solutions.

The Warehouse Tool Management Challenge

Modern warehouses operate under immense pressure to maximize efficiency while minimizing operational costs. Tool management challenges significantly impact warehouse performance:

Tool retrieval delays: Workers spend valuable time searching for equipment across multiple warehouse zones

Inventory management issues: Poor tool tracking leads to losses, misplacement, and replacement costs

Workflow disruptions: Unavailable tools delay critical warehouse operations

Safety concerns: Disorganized tools create workplace hazards and injury risks

Space utilization inefficiencies: Fixed storage solutions waste valuable warehouse space

Industry studies reveal that warehouse workers lose approximately 12-15 minutes daily searching for tools, translating to over 60 hours annually per employee – a significant productivity drain that impacts bottom-line results.

Rolling Tool Carts: The Warehouse Organization Revolution

Strategic Implementation Framework

1. Warehouse Zone Analysis and Tool Mapping

Before implementing rolling tool carts, conduct a comprehensive warehouse analysis:

Zone-Based Tool Classification

Receiving areas: Tools for unpacking, inspection, and initial processing

Storage zones: Equipment for inventory management, labeling, and organization

Picking stations: Tools for order fulfillment, packing, and preparation

Shipping departments: Equipment for final processing, labeling, and dispatch

Maintenance sections: Tools for equipment repair, facility upkeep, and safety

Tool Usage Pattern Analysis

| Tool Category | Usage Frequency | Storage Priority | Cart Placement |

|---|

Box cutters/utility knives | Daily | High | Multiple zones |

Measuring devices | Daily | High | All stations |

Labeling equipment | Daily | High | Shipping/receiving |

Repair tools | Weekly | Medium | Maintenance areas |

Safety equipment | As needed | Variable | All zones |

2. Rolling Tool Cart Configuration Strategies

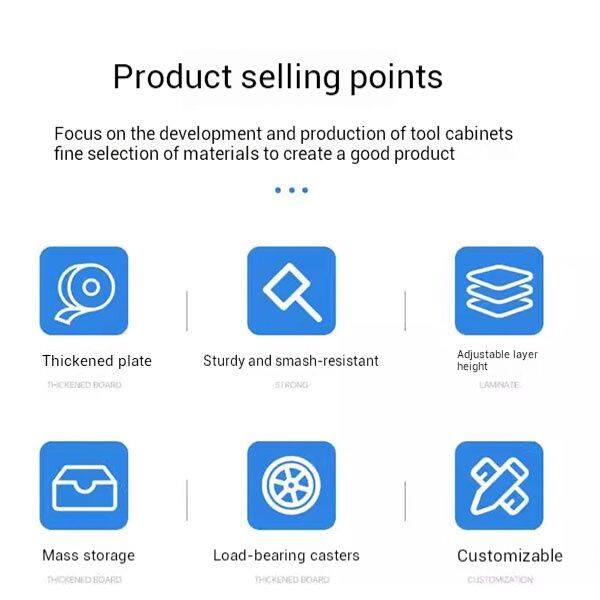

Based on the multi-drawer designs shown in reference images, warehouse tool carts should feature:

Optimal Drawer Configuration

Five-drawer systems: Comprehensive tool categorization for diverse warehouse needs

Progressive depth design: Shallow top drawers (2-3 inches) for small items, deeper bottom drawers (8-12 inches) for bulky equipment

Weight distribution strategy: Heavy tools in bottom drawers for stability, frequently used items in top drawers for accessibility

Customizable dividers: Flexible compartment creation adapting to changing warehouse requirements

Warehouse-Specific Mobility Features

Heavy-duty casters: 5-6 inch polyurethane wheels supporting 500+ lbs loads

360-degree rotation: Swivel casters enabling tight warehouse navigation

Locking mechanisms: Secure positioning during tool retrieval and usage

Floor protection: Non-marking wheels suitable for various warehouse flooring surfaces

3. Advanced Tool Organization Systems

Categorization Methodologies

By Operational Function

Receiving tools: Box cutters, utility knives, measuring tapes, inspection equipment

Storage equipment: Label makers, inventory scanners, organization tools, marking devices

Picking tools: Order pickers, packing equipment, safety gear, cutting tools

Shipping supplies: Tape dispensers, labeling tools, security devices, strapping equipment

Maintenance tools: Repair kits, lubrication supplies, safety equipment, diagnostic tools

By Usage Frequency and Priority

Critical daily tools: Most frequently accessed items in top drawers with clear labeling

Regular weekly equipment: Medium-frequency tools in easily accessible middle drawers

Occasional monthly supplies: Less frequently used items in organized bottom drawers

Seasonal equipment: Specialized tools stored separately but marked for easy access

Warehouse Workflow Optimization Strategies

1. Strategic Cart Placement and Distribution

High-Traffic Area Positioning

Workstation proximity: Position carts within 10-15 feet of primary work areas

Intersection points: Central locations serving multiple warehouse zones efficiently

Break area access: Convenient tool availability during employee rest periods

Training station integration: Dedicated carts supporting new employee training programs

Mobile Tool Distribution Networks

Zone-specific carts: Dedicated rolling carts for different warehouse functional areas

Shared resource stations: Mobile carts rotating between high-demand locations

Specialized equipment carts: Task-specific tool collections for particular operations

Emergency response carts: Critical tools positioned for urgent situation access

2. Employee Training and System Adoption

Comprehensive Training Programs

Tool organization protocols: Standardized systems for consistent tool arrangement

Cart operation procedures: Proper use, maintenance, and safety guidelines

Accountability systems: Individual responsibility for tool management and care

Safety procedures: Proper tool handling, cart operation, and workplace safety

Continuous Improvement Framework

Regular feedback collection: Monthly employee input on organization effectiveness

Usage pattern analysis: Quarterly data-driven optimization of tool placement

System adjustment protocols: Regular updates based on operational changes

Performance monitoring: Weekly tracking of efficiency improvements and results

Measuring Success: Warehouse Efficiency Metrics

Financial Impact Analysis

Revenue Enhancement Opportunities

Increased throughput capacity: 15-25% improvement in daily processing volume

Reduced labor costs: 10-15% decrease in overtime requirements

Improved order accuracy: Better tool access reducing processing errors

Enhanced customer satisfaction: Faster order fulfillment improving retention

Cost Reduction Benefits

Tool management savings: 60-70% reduction in replacement and loss costs

Labor efficiency gains: 20-30% improvement in employee productivity

Safety cost reduction: Fewer workplace incidents lowering insurance premiums

Space optimization: Better organization reducing storage facility costs

Advanced Technology Integration

Smart Warehouse Tool Management

RFID tracking systems: Automated tool inventory and location monitoring

Digital check-out/check-in: Streamlined tool accountability and usage tracking

Mobile app integration: Real-time tool location and availability information

Analytics platforms: Data-driven insights for continuous optimization

Warehouse Management System (WMS) Integration

Inventory synchronization: Tool cart integration with existing WMS platforms

Automated reordering: Smart systems triggering tool replacement orders

Usage analytics: Detailed reporting on tool utilization patterns

Maintenance scheduling: Automated alerts for tool maintenance and replacement

Implementation Best Practices

1. Phased Rollout Strategy

Pilot program testing: Initial implementation in one warehouse zone

Performance measurement: Detailed tracking of pilot program results

System refinement: Optimization based on pilot program feedback

Full-scale deployment: Gradual expansion across entire warehouse facility

2. Change Management Excellence

Stakeholder communication: Regular updates on implementation progress and benefits

Employee involvement: Including warehouse staff in selection and organization decisions

Training reinforcement: Ongoing education and support programs

Success celebration: Recognition of improvements and achievement milestones

Tags: Improve Tool Organization, Warehouse with Rolling Tool Carts, Rolling Tool Carts