Maintenance Guide: Extending the Life of Stainless Steel Water Bottle Storage

Comprehensive Care Strategies for Long-Lasting Storage Solutions

Stainless steel water bottle storage systems represent significant investments for commercial facilities, educational institutions, and fitness centers. Proper maintenance not only protects this investment but also ensures optimal performance, hygiene standards, and aesthetic appeal throughout the product’s extended service life. This comprehensive maintenance guide provides detailed strategies for extending the life of your stainless steel storage solutions while maximizing their functional and economic value.

Understanding Stainless Steel Properties and Maintenance Requirements

Material Science Fundamentals

304 stainless steel—the industry standard for water bottle storage—contains specific alloy compositions that provide exceptional corrosion resistance and durability. Understanding these material properties is essential for implementing effective maintenance protocols.

Key Material Characteristics:

Chromium Content: 18% minimum creates protective oxide layer

Nickel Content: 8% minimum enhances corrosion resistance

Non-Porous Surface: Prevents bacterial penetration and facilitates cleaning

Self-Healing Properties: Passive oxide layer reforms after minor damage

Temperature Tolerance: Performs consistently across diverse environmental conditions

Common Maintenance Challenges

Stainless steel water bottle storage faces specific environmental and usage challenges that require targeted maintenance approaches.

Maintenance Challenge Analysis:

Environmental Exposure: Humidity, temperature fluctuations, chemical contact

Usage Patterns: High-frequency access, mechanical stress, accidental impacts

Cleaning Chemical Interactions: Potential damage from inappropriate cleaning agents

Biological Growth: Bacterial colonization in moist environments

Physical Damage: Scratches, dents, and structural stress points

Daily Maintenance Procedures

Routine Cleaning Protocols

Effective daily maintenance establishes the foundation for long-term stainless steel preservation and optimal hygiene standards.

Essential Daily Tasks:

Surface Wiping: Use microfiber cloths with pH-neutral cleaners for exterior surfaces

Spill Management: Immediate cleanup of liquids to prevent staining and corrosion

Compartment Inspection: Visual assessment for debris or contamination

Hardware Check: Verify lock mechanisms and hinges operate smoothly

Documentation: Record daily maintenance activities for compliance tracking

Recommended Cleaning Solutions:

pH-Neutral Detergents: Commercial-grade cleaners specifically formulated for stainless steel

Distilled Water: Prevents mineral deposits from tap water

Microfiber Cloths: Non-abrasive material prevents surface scratching

Soft Brushes: For detailed cleaning of corners and crevices

Protective Coatings: Optional application of stainless steel protectants

User Education and Engagement

Maintenance effectiveness depends significantly on proper user behavior and engagement with care protocols.

User Training Components:

Proper Usage Guidelines: Correct opening/closing procedures to prevent damage

Spill Reporting: Immediate notification of liquid spills or contamination

Gentle Handling: Techniques to minimize mechanical stress and impact damage

Cleaning Responsibility: User accountability for personal storage compartments

Damage Reporting: Prompt notification of maintenance issues or concerns

Weekly Deep Cleaning Protocols

Comprehensive Sanitization Procedures

Weekly deep cleaning addresses accumulated contaminants and maintains optimal hygiene standards for water bottle storage systems.

Deep Cleaning Process:

Empty Compartments: Remove all contents for thorough access

Surface Preparation: Initial wipe-down to remove loose debris

Cleaning Solution Application: Apply appropriate stainless steel cleaner

Detail Brushing: Use soft brushes for detailed cleaning

Rinse and Dry: Thorough drying prevents water spots and corrosion

Hardware Maintenance: Lubricate moving parts and check tightness

Inspection: Assess for damage or wear requiring attention

Sanitization Standards:

Temperature Requirements: Use water at appropriate temperatures for effective cleaning

Contact Time: Allow cleaning solutions to remain on surfaces for recommended duration

Rinse Procedures: Thorough removal of cleaning chemical residues

Drying Methods: Air drying or soft cloth drying to prevent water spots

Verification: Visual inspection for cleanliness and surface integrity

Monthly Maintenance and Inspection

Structural Integrity Assessment

Monthly comprehensive inspections identify potential issues before they become significant problems, ensuring continued extending the life of storage systems.

Inspection Checklist:

Surface Condition: Check for scratches, corrosion, or discoloration

Weld Integrity: Examine welded joints for separation or corrosion

Hardware Function: Test locks, hinges, and mounting hardware

Structural Stability: Verify cabinet remains level and secure

Seal Condition: Check door seals and gaskets for wear or damage

Ventilation Assessment: Ensure adequate air circulation around storage units

Preventive Maintenance Tasks

Proactive maintenance prevents common issues and extends service life significantly.

Preventive Maintenance Activities:

Hardware Tightening: Check and tighten all bolts, screws, and fasteners

Lubrication Application: Apply appropriate lubricants to moving parts

Seal Replacement: Replace worn or damaged seals and gaskets

Surface Protection: Apply protective coatings as recommended

Alignment Adjustment: Ensure doors and compartments operate smoothly

Documentation Update: Record all maintenance activities and observations

Seasonal Maintenance Considerations

Environmental Adaptation Strategies

Seasonal variations require specific maintenance approaches to address changing environmental conditions.

Spring Maintenance Focus:

Pollen Removal: Increased cleaning frequency during high pollen periods

Allergen Control: Enhanced cleaning protocols for allergy-sensitive environments

Ventilation Improvement: Address increased humidity and temperature changes

Hardware Adjustment: Compensate for temperature-related expansion/contraction

Summer Maintenance Priorities:

Humidity Management: Increased cleaning frequency in high-humidity conditions

Corrosion Prevention: Enhanced inspection for moisture-related issues

Temperature Protection: Address direct sunlight exposure and heat effects

Usage Pattern Adaptation: Adjust maintenance schedules for increased usage

Fall Maintenance Requirements:

Debris Management: Address increased leaf and organic material exposure

Temperature Transition: Prepare systems for cooler weather conditions

Ventilation Adjustment: Modify air circulation for seasonal changes

Hardware Inspection: Check for weather-related wear and tear

Winter Maintenance Considerations:

Condensation Prevention: Address moisture accumulation from temperature differentials

Freeze Protection: Prevent water damage from freezing conditions

Heating System Impact: Address dry air effects on stainless steel surfaces

Reduced Ventilation: Adjust cleaning protocols for indoor air quality changes

Troubleshooting Common Issues

Identification and Resolution Strategies

Effective troubleshooting requires systematic identification of problems and appropriate resolution techniques.

Common Issues and Solutions:

Surface Discoloration: Usually caused by improper cleaning or chemical exposure

Corrosion Spots: Often result from prolonged moisture contact or chemical damage

Sticking Mechanisms: Typically caused by debris accumulation or lack of lubrication

Loose Hardware: Results from vibration or normal wear over time

Odor Development: Indicates bacterial growth or trapped moisture

Resolution Procedures:

Problem Identification: Thorough inspection to determine root cause

Cleaning Assessment: Evaluate current cleaning effectiveness

Repair Planning: Determine appropriate repair or replacement actions

Implementation: Execute corrective actions using proper techniques

Verification: Confirm problem resolution and system functionality

Documentation: Record issues and resolutions for future reference

Professional Maintenance Services

When to Engage Professional Services

Professional maintenance becomes necessary for complex issues or comprehensive system servicing.

Professional Service Indicators:

Structural Damage: Significant dents, cracks, or deformation

Weld Failure: Broken or corroded welded joints

System Replacement: Complete component or system replacement needs

Specialized Cleaning: Deep cleaning requiring industrial equipment

Compliance Certification: Third-party verification for regulatory requirements

Service Provider Selection Criteria:

Industry Experience: Proven expertise with stainless steel systems

Certification Requirements: Appropriate licenses and certifications

Insurance Coverage: Comprehensive liability and workers’ compensation

Reference Verification: Positive customer feedback and proven track record

Cost Transparency: Clear pricing structure and detailed quotes

Cost-Benefit Analysis of Maintenance Investment

Financial Impact Analysis

ROI Calculation

Maintenance ROI becomes evident when considering total cost of ownership and operational benefits.

ROI Components:

Replacement Cost Avoidance: Significant savings through extended service life

Operational Efficiency: Reduced downtime and improved functionality

Compliance Benefits: Avoidance of regulatory violations and penalties

Aesthetic Maintenance: Professional appearance preservation

User Satisfaction: Improved experience through reliable functionality

Strategic Maintenance Investment

Extending the life of stainless steel water bottle storage systems requires systematic, proactive maintenance approaches that protect investments while ensuring optimal performance. The combination of daily care, periodic deep cleaning, seasonal adjustments, and professional services creates comprehensive protection that maximizes value over the system’s entire lifecycle.

The financial benefits of proper maintenance extend far beyond simple cost avoidance to include enhanced operational efficiency, regulatory compliance, and user satisfaction. For facility managers seeking to optimize their storage investments, implementation of comprehensive maintenance protocols represents a strategic decision that delivers measurable returns while supporting organizational objectives.

By following the detailed maintenance guidelines outlined in this guide, facilities can ensure their stainless steel water bottle storage systems continue to provide reliable, hygienic, and attractive storage solutions for decades rather than years, maximizing both functional and economic value.

Recently Posted

-

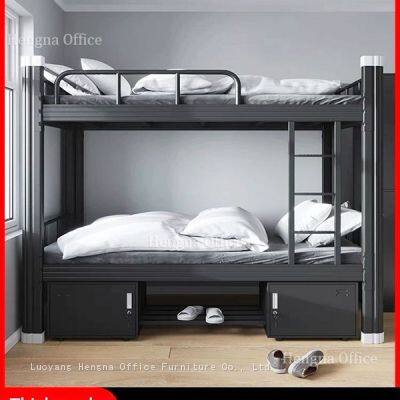

School Dorm Bunk Bed Buying Guide: Let Your Kids Sleep in Their Own Cozy Haven

December 30, 2025Selecting the perfect dormitory bed for schools is more than just picking a piece of furniture—it’s about creating a safe, comfort Read More

Read More -

Stop Smelly Mops! Why Your Facility Needs a Drainage-First Janitorial Cabinet

December 30, 2025Mops are essential tools in any facility, from hospitals to gyms, schools, and hotels. However, there's a dirty little se Read More

Read More -

Beyond the Bucket: Why Every Gym Needs a Dedicated Mop & Towel Drying Hub

December 30, 2025Maintaining a clean, hygienic gym is no longer optional—it’s essential for member safety, satisfaction, and retention. From spille Read More

Read More -

Messy Closet, Messy Business: Transforming Your Housekeeping Efficiency Overnight

December 30, 2025A disorganized housekeeping closet isn’t just an eyesore—it’s a productivity killer. In hotels, hospitals, and large facilities, j Read More

Read More