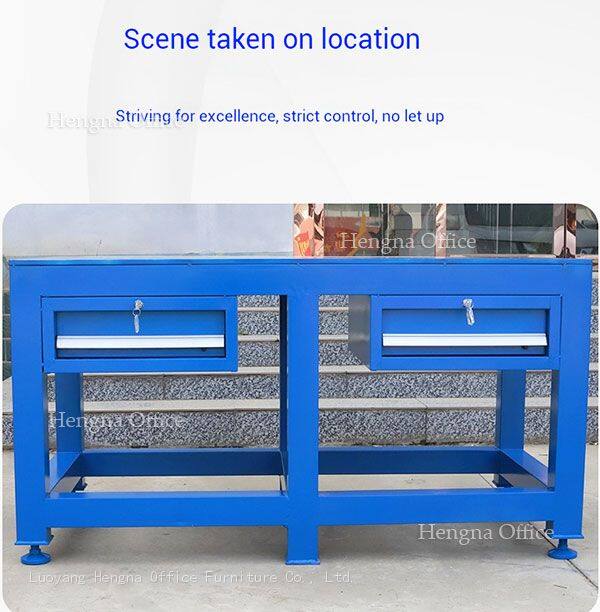

Standard vs. Customized: Which Industrial Workbench Fits Your Factory Layout?

When designing an efficient factory layout, selecting the right industrial workbenches represents a critical decision that impacts productivity, workflow efficiency, and operational costs. Facility managers and production planners often face the dilemma between choosing standard off-the-shelf workbenches and investing in customized solutions tailored to their specific requirements. This comprehensive analysis examines the factors influencing this decision, helping you determine which approach best suits your factory layout and operational needs.

Understanding Standard Industrial Workbenches

Definition and Characteristics

Standard industrial workbenches are pre-designed, mass-produced workstations manufactured in common dimensions and configurations. These typically feature fixed specifications including standard heights (34-36 inches), common lengths (48-72 inches), and standard depths (24-36 inches). Standard workbenches usually come with predetermined drawer configurations, surface materials, and load capacities ranging from 1000-2000kg.

Advantages of Standard Workbenches

Immediate Availability: Standard workbenches are typically stocked by manufacturers and distributors, allowing for quick deployment without extended lead times. This immediate availability proves crucial for facilities requiring rapid expansion or replacement of damaged equipment.

Cost Efficiency: Mass production economies make standard workbenches significantly more affordable than customized alternatives. Prices typically range from 30-50% lower than comparable custom solutions, making them attractive for budget-conscious operations.

Proven Performance: Standard workbenches have undergone extensive testing and real-world validation across numerous industrial applications. Their designs have been refined based on user feedback and performance data, ensuring reliable functionality.

Easy Replacement and Expansion: Standardized dimensions and configurations simplify future expansions and replacements. When additional workstations are needed, matching existing units ensures consistency in appearance and functionality.

Limitations of Standard Solutions

Space Utilization Challenges: Standard dimensions may not optimize available floor space, leading to inefficient layouts or wasted areas. This inefficiency becomes particularly problematic in facilities with unique architectural features or space constraints.

Workflow Incompatibility: Fixed configurations may not align with specific operational workflows, potentially creating bottlenecks or requiring workers to adapt their processes to accommodate equipment limitations rather than optimizing processes for maximum efficiency.

Customized Industrial Workbenches: Tailored Solutions

Customization Capabilities

Customized industrial workbenches offer extensive modification options including:

Dimensional customization to perfectly fit available spaces and workflow requirements

Specialized surface materials selected for specific industrial applications and chemical resistance

Integrated equipment mounting for monitors, tools, and specialized equipment

Advanced storage solutions designed for specific tool sets and operational needs

Built-in utilities including power distribution, data ports, and specialized connections

Benefits of Customized Solutions

Optimized Space Utilization: Custom workbenches can be designed to maximize every inch of available floor space, including areas with unusual dimensions or architectural constraints. This optimization proves particularly valuable in urban facilities where space comes at a premium.

Enhanced Workflow Integration: Custom solutions can be designed around specific operational processes, eliminating workflow disruptions and maximizing productivity. This integration includes considerations for tool placement, material flow, and operator movement patterns.

Specialized Application Support: Industries with unique requirements—such as cleanroom environments, hazardous material handling, or specialized manufacturing processes—benefit from workbenches designed specifically for their needs.

Future-Proofing: Custom workbenches can be designed with modularity and adaptability in mind, allowing for future modifications as operational requirements evolve without requiring complete replacement.

Considerations for Custom Solutions

Extended Lead Times: Custom workbenches typically require 6-12 weeks for design, manufacturing, and delivery, significantly longer than standard solutions’ immediate availability.

Higher Initial Investment: Custom solutions command premium prices, typically 40-70% higher than comparable standard workbenches due to specialized design, engineering, and manufacturing processes.

Decision-Making Framework

Facility Layout Analysis

Begin by conducting a comprehensive analysis of your factory layout:

Space constraints including architectural features, column placements, and utility connections

Workflow patterns analyzing material flow, operator movement, and process sequences

Future expansion plans considering potential layout modifications and operational growth

Equipment integration requirements identifying specialized tools, monitors, or utility needs

Operational Requirements Assessment

Evaluate specific operational needs:

Load capacity requirements considering both current and future equipment needs

Storage demands analyzing tool inventories, material requirements, and organization preferences

Specialized environmental factors including cleanroom requirements, chemical exposure, or temperature considerations

Ergonomic requirements addressing operator comfort, safety, and productivity needs

Cost-Benefit Analysis

Compare total cost of ownership over expected lifespan:

Initial investment differences between standard and custom solutions

Productivity impacts measuring potential efficiency gains from optimized layouts

Flexibility considerations evaluating future modification capabilities

Replacement costs analyzing long-term equipment lifecycle expenses

Industry-Specific Considerations

Manufacturing Facilities

Manufacturing operations often benefit from customized solutions due to:

Complex workflow requirements involving multiple process stages

Specialized equipment integration including monitors, testing equipment, and specialized tools

Material handling considerations requiring specific height and access configurations

Quality control requirements necessitating specialized surfaces and storage solutions

Assembly Operations

Assembly operations may find standard solutions adequate when:

Standardized processes follow consistent patterns across multiple workstations

Tool requirements remain consistent across different assembly stations

Future flexibility is valued over current optimization

Budget constraints prioritize immediate deployment over perfect optimization

Maintenance and Repair Facilities

Maintenance operations often require customized solutions due to:

Variable equipment sizes requiring adaptable work surfaces

Specialized tool storage needs for diverse equipment types

Utility integration requirements including compressed air, electrical connections, and data ports

Accessibility considerations for equipment maintenance and repair operations

Hybrid Approaches: Best of Both Worlds

Many facilities find success combining standard and customized approaches:

Standard core configurations with customized accessories and modifications

Modular systems allowing future customization as requirements evolve

Phased implementation starting with standard solutions and upgrading to custom where most beneficial

Implementation Strategies

Pilot Programs

Consider implementing pilot programs comparing standard and customized solutions in similar operational areas. This approach allows real-world performance evaluation before full-scale investment.

Phased Rollout

Implement solutions gradually, starting with areas where benefits are most significant or where problems with current arrangements are most acute.

Continuous Evaluation

Regularly assess workstation performance and user feedback to identify optimization opportunities and justify future investments.

The decision between standard and customized industrial workbenches requires careful consideration of multiple factors including facility layout, operational requirements, budget constraints, and long-term strategic goals. While standard solutions offer immediate availability and cost advantages, customized workbenches provide optimized performance and specialized functionality.

The optimal approach often depends on your specific operational context, with many facilities finding success through hybrid solutions that balance cost-effectiveness with performance optimization. By conducting thorough analysis and considering both immediate needs and future requirements, facility managers can make informed decisions that enhance productivity while controlling costs.

Ultimately, the best solution is one that aligns with your operational workflows, optimizes space utilization, and provides the flexibility to adapt to future changes in your manufacturing environment. Whether standard, customized, or hybrid, the right workbench choice becomes a foundation for operational excellence and competitive advantage.

Recently Posted

-

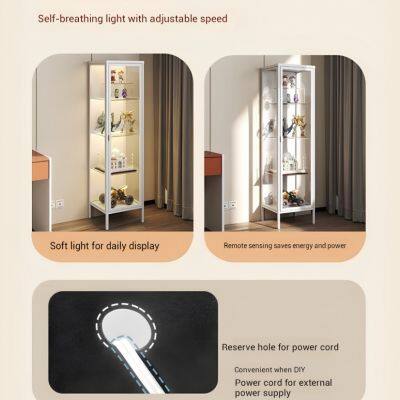

First Sight at the Entryway: How Sensor-Lit Display Cabinets Define Your Home’s Style

January 8, 2026They say you never get a second chance to make a first impression. In the world of interior design, the entryway (foyer) is the &q Read More

Read More -

Farewell to "Spider Webs": How Hidden Cable Management Holes Elevate Your Display Cabinet's Premium

January 8, 2026In the world of high-end collecting and retail display, there is a silent enemy that ruins even the most expensive setups: The Spi Read More

Read More -

Safety Beyond the Lock: Why 3C Tempered Glass, Rounded Corners, and Anti-Tip Kits Are Non-Negotiable

January 8, 2026When we think about "securing" a display cabinet, our minds immediately go to the lock. We think about protecting the co Read More

Read More -

How to Design a Safe and Sanitary Nursing Room in Public Spaces?

January 8, 2026The Business Case for Family-Friendly SpacesIn the modern commercial landscape, the quality of a facility is often judged by its m Read More

Read More