-

Sarah

Hi there! Welcome to my shop. Let me know if you have any questions.

Sarah

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

Auto Shop Safety: Best Practices for Flammable Liquid Storage with Gallon Cabinets

2025-11-06 13:38:28

Automotive repair shops handle numerous flammable liquids including gasoline, diesel fuel, oils, solvents, and cleaning agents that require specialized storage solutions to ensure workplace safety and regulatory compliance. The implementation of proper flammable liquid storage systems using gallon cabinets represents a critical safety measure that protects both workers and business operations. This comprehensive guide explores best practices for flammable liquid storage in automotive repair facilities and how proper implementation can enhance safety while maintaining operational efficiency.

Identifying Automotive Shop Flammable Liquids

Automotive repair shops must first identify and categorize all flammable liquids used in their operations to implement appropriate storage solutions. Common flammable liquids include gasoline and diesel fuel, which are Class I flammable liquids requiring the most stringent storage requirements. Additionally, shops handle various oils, transmission fluid, brake fluid, and cleaning solvents that may have different storage requirements based on their flash points and chemical properties.

The identification process should include a comprehensive inventory of all flammable liquids, their quantities, storage locations, and usage patterns. This inventory helps determine the appropriate number and size of storage cabinets needed, as well as their optimal placement within the facility. Different automotive services may require different storage configurations, with general repair shops needing versatile storage solutions and specialty shops requiring more specific storage arrangements.

OSHA Compliance for Automotive Facilities

Automotive repair shops must comply with OSHA’s flammable liquid storage standards, which specify requirements for container types, storage quantities, and cabinet construction. The regulations limit the amount of flammable liquids that can be stored outside of approved cabinets, making proper cabinet implementation essential for compliance. Automotive shops should familiarize themselves with these requirements to ensure their storage practices meet or exceed federal standards.

Compliance considerations extend beyond federal regulations to include state and local fire codes that may have additional requirements. Automotive shops should work with local fire marshals and safety consultants to ensure their storage solutions meet all applicable requirements. Regular compliance audits and inspections help maintain ongoing compliance and identify potential issues before they become serious problems.

Cabinet Placement and Shop Layout

Strategic placement of flammable liquid cabinets within automotive shops is crucial for both safety and operational efficiency. Cabinets should be located away from heat sources, ignition sources, and high-traffic areas while remaining accessible for authorized personnel. The placement should consider the flow of work in the shop, minimizing the distance workers must travel to access stored liquids while maintaining safe separation from potential hazards.

Shop layout considerations should include emergency access routes, fire extinguisher placement, and spill containment measures. Flammable liquid cabinets should be positioned to allow emergency access while not obstructing evacuation routes or firefighting equipment. Some automotive shops implement secondary containment areas around cabinets to provide additional spill protection and environmental safety.

Ventilation and Air Quality Management

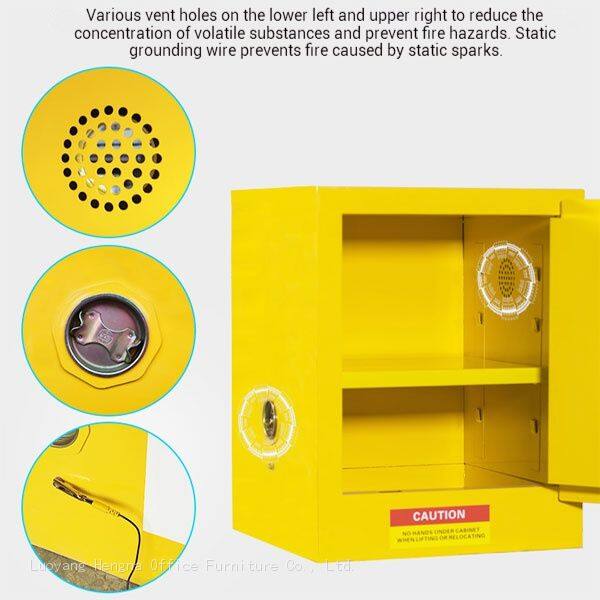

Proper ventilation is essential in automotive shops where chemical vapors can accumulate from stored flammable liquids and vehicle repair activities. Flammable liquid cabinets should be integrated with the shop’s ventilation system to ensure adequate air exchange and vapor removal. Cabinet vents should be positioned to promote proper air circulation while preventing flame entry during fire incidents.

Automotive shops may require specialized ventilation solutions based on their specific layout and the types of chemicals stored. Some facilities implement local exhaust ventilation systems that connect directly to cabinet vents, providing enhanced vapor removal and air quality control. The integration of cabinet ventilation with the shop’s overall ventilation strategy ensures comprehensive air quality management and worker protection.

Employee Training and Safety Protocols

Even the most advanced flammable liquid storage systems require proper employee training to ensure effective implementation and safe operation. Automotive shop workers should understand the specific hazards associated with stored flammable liquids, proper cabinet operation procedures, and emergency response protocols. Regular training sessions should cover cabinet inspection, maintenance requirements, and proper handling of stored liquids.

Safety protocols should be clearly documented and regularly practiced through drills and simulations. Employees should know how to respond to spills, leaks, or fires involving flammable liquids, including proper evacuation procedures and emergency equipment usage. The integration of cabinet-specific safety procedures into the shop’s overall safety program ensures comprehensive preparedness and rapid response to potential incidents.

Spill Containment and Environmental Protection

Automotive shops must implement spill containment measures to protect both workers and the environment from accidental releases of flammable liquids. Flammable liquid cabinets should be equipped with spill containment features that prevent leaks from spreading beyond the cabinet area. Some shops implement secondary containment systems that provide additional protection against spills and environmental contamination.

Environmental protection considerations extend to proper disposal of contaminated materials and cleanup procedures. Automotive shops should maintain spill response kits with appropriate absorbents, neutralizers, and personal protective equipment. Regular training on spill response procedures ensures that workers can respond quickly and effectively to accidental releases, minimizing environmental impact and ensuring regulatory compliance.

Integration with Shop Management Systems

Modern automotive shops increasingly utilize management systems for inventory control, maintenance scheduling, and safety compliance. Flammable liquid storage cabinets can integrate with these systems through barcode scanning, RFID technology, or digital inventory management. This integration creates comprehensive chemical management that supports shop efficiency and regulatory compliance.

System integration benefits extend to tracking chemical usage, monitoring inventory levels, and automating reordering processes. Some automotive shops implement smart storage systems that provide real-time data on chemical inventory and usage patterns. These technological capabilities enhance shop efficiency and support data-driven decision making for chemical management and safety compliance.

Maintenance and Inspection Procedures

Regular maintenance and inspection of flammable liquid storage cabinets are essential for maintaining safety performance and regulatory compliance. Automotive shops should establish comprehensive inspection schedules that include daily visual checks, weekly functional tests, and annual professional inspections. These inspections should cover all cabinet components including doors, locks, vents, grounding connections, and structural integrity.

Maintenance procedures should address any identified issues promptly to prevent potential safety hazards. Cabinet doors should close and latch properly, vents should remain clear of obstructions, and grounding connections should maintain secure contact with earth ground. Documentation of all inspections and maintenance activities creates a comprehensive record that demonstrates compliance and supports continuous improvement of safety protocols.

Tags: Auto Shop Safety, Flammable Liquid Storage, Gallon Cabinets