-

Sarah

Hi there! Welcome to my shop. Let me know if you have any questions.

Sarah

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

Corrosion-Proof Tool Cabinets for Marine Workshops: Protect Your Investment

2025-11-05 13:51:43

Marine workshops face unique challenges due to constant exposure to saltwater, humidity, and harsh marine environments that rapidly deteriorate standard tool storage solutions. Corrosion-proof tool cabinets have become essential investments for marine professionals, protecting valuable tools from the destructive effects of marine environments while maintaining organization and accessibility. This comprehensive guide explores corrosion-resistant tool storage solutions designed specifically for marine applications and their critical role in protecting tool investments.

Understanding Marine Environment Challenges

Marine environments present some of the most corrosive conditions for metal tools and equipment, with saltwater spray, high humidity, and temperature fluctuations creating perfect conditions for rapid rust formation. Standard tool cabinets, even those with basic corrosion protection, quickly succumb to these harsh conditions, leading to tool damage, reduced functionality, and premature failure.

The marine environment challenges extend beyond simple corrosion to include constant exposure to moisture, salt accumulation, and UV radiation. These factors combine to create exceptionally demanding storage requirements that exceed the capabilities of standard workshop storage solutions. Marine professionals need specialized storage systems engineered specifically to withstand these conditions while maintaining tool organization and accessibility.

Advanced Corrosion-Resistant Materials

Marine-grade tool cabinets utilize advanced materials specifically chosen for their corrosion resistance and durability in marine environments. Stainless steel construction, particularly 316 marine-grade stainless, provides superior resistance to saltwater corrosion and chemical exposure. Some marine cabinets incorporate specialized alloys or coatings that offer enhanced protection against marine conditions.

Material innovations extend to include specialized polymers, composites, and advanced coatings that resist saltwater degradation. Some marine tool cabinets feature anodized aluminum components that provide excellent corrosion resistance while reducing weight. These advanced materials ensure long-term performance in demanding marine environments and protect valuable tool investments.

Specialized Marine Coatings and Finishes

Marine tool cabinets incorporate specialized coating systems designed specifically for harsh marine environments. Epoxy powder coatings with marine-grade formulations provide superior protection against saltwater corrosion and UV damage. Some cabinets feature multi-layer coating systems that include primers, intermediate coats, and topcoats specifically formulated for marine applications.

Coating innovations extend to include self-healing coatings that can repair minor scratches automatically, maintaining continuous protection against corrosion. Some marine tool cabinets feature anti-fouling coatings that prevent marine organism growth in submerged applications. These specialized coating systems ensure long-lasting protection and reduce maintenance requirements in marine environments.

Sealed Construction and Weather Protection

Marine tool storage requires completely sealed construction that prevents moisture and saltwater infiltration. Marine-grade cabinets feature sealed drawer mechanisms, weather-stripped doors, and gasketed compartments that create watertight storage environments. Some models incorporate pressure-equalization vents that prevent vacuum lock while maintaining moisture protection.

Weather protection extends to supporting various marine scenarios including dockside work, boat maintenance, and offshore operations. Some marine tool cabinets feature elevated bases or waterproof seals that protect contents even during temporary submersion. These weather protection features ensure reliable performance regardless of marine conditions and protect tools from water damage.

Supporting Various Marine Trades

Marine workshops encompass various specialties including boat building, marine engine repair, electrical systems, and hull maintenance, each with unique tool requirements. Marine tool storage systems must accommodate these diverse needs through flexible configurations that support different marine trades while maintaining corrosion resistance.

Marine workshops encompass various specialties including boat building, marine engine repair, electrical systems, and hull maintenance, each with unique tool requirements. Marine tool storage systems must accommodate these diverse needs through flexible configurations that support different marine trades while maintaining corrosion resistance.

Different marine specialties may require specialized storage for particular tools or equipment. Boat builders need storage for woodworking tools, marine-grade fasteners, and finishing equipment. Marine mechanics require storage for engine tools, diagnostic equipment, and specialized marine engine components. Marine electrical specialists need storage for wiring tools, corrosion testing equipment, and marine-grade electrical components.

Integration with Marine Workflows

Marine work often occurs in challenging conditions with limited space and time constraints. Tool storage systems should support marine workflows through organization that enables quick tool access and efficient work completion. Some marine tool cabinets feature specialized compartments for frequently used marine tools like wrenches, pliers, and specialized marine equipment.

Workflow integration benefits extend to supporting various marine maintenance tasks including hull repairs, engine servicing, and electrical system maintenance. Organized tool storage enables marine professionals to work efficiently in challenging conditions and complete projects on schedule. Some marine cabinets feature external tool storage or quick-access compartments for items needed frequently during marine work.

Mobility for Marine Environments

Marine work often requires tool mobility between different locations including docks, boat yards, and vessel locations. Marine tool cabinets should incorporate mobility features that work effectively in marine environments. All-terrain casters with corrosion-resistant materials enable movement across various surfaces including docks, boat ramps, and uneven terrain.

Mobility considerations extend to transportation between different work sites or vessels. Some marine tool cabinets feature forklift pockets or lifting points that facilitate easy movement with marine equipment. Compact designs enable transport on boats or work vessels without requiring specialized equipment. These mobility features enhance flexibility and efficiency in marine operations.

Security for Marine Applications

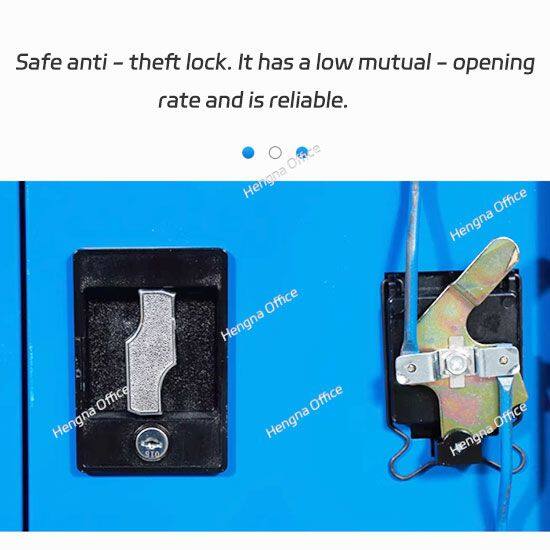

Marine tools represent significant investments that require protection even in remote or unsecured marine locations. Marine tool cabinets should incorporate security features that withstand marine conditions while preventing unauthorized access. Heavy-duty locking mechanisms with corrosion-resistant materials provide reliable security in marine environments.

Security considerations extend to protecting tools from theft during vessel storage or when working in public marine areas. Some marine tool cabinets feature cable-down points or anchoring systems that prevent cabinet theft. These security features protect valuable tool investments and provide peace of mind for marine professionals working in various locations.

Maintenance and Longevity in Marine Conditions

Marine tool cabinets require minimal maintenance while providing reliable performance in harsh conditions. Self-lubricating drawer slides and corrosion-resistant hardware reduce maintenance requirements and ensure smooth operation despite saltwater exposure. Some marine cabinets feature easy-clean surfaces that resist salt accumulation and facilitate regular maintenance.

Longevity considerations include resistance to UV damage, impact resistance, and structural integrity under marine conditions. Marine-grade tool cabinets should maintain functionality and appearance despite constant exposure to harsh marine environments. These durability features ensure long-term value and consistent marine conditions. These durability features ensure long-term value and consistent performance throughout the cabinet’s service life, even in the most challenging marine environments.

Maintenance Requirements for Marine Environments

Marine tool cabinets should require minimal maintenance while providing reliable performance in harsh conditions. Self-lubricating drawer slides with marine-grade materials ensure smooth operation despite saltwater exposure and reduce the need for regular maintenance. Some marine cabinets feature easy-clean surfaces that resist salt accumulation and facilitate regular cleaning with fresh water.

Maintenance considerations extend to accessibility for routine inspections and cleaning procedures. Marine tool cabinets should be designed for easy access to all components for maintenance and inspection. Some models feature removable drawer units or accessible hardware that simplifies maintenance procedures. These design features ensure that marine professionals can maintain their tool storage systems with minimal time and effort, allowing them to focus on their primary marine work activities.

Cost-Effectiveness and Investment Protection

Marine-grade tool cabinets represent significant investments that must deliver value through superior corrosion protection and extended service life. While initial costs may exceed standard tool cabinets, the long-term benefits include reduced tool replacement costs, extended equipment life, and enhanced operational efficiency. The ability to protect valuable tools from corrosion damage directly impacts the total cost of ownership.

Cost-effectiveness extends to supporting various marine business objectives including operational efficiency, customer satisfaction, and regulatory compliance. Proper tool storage prevents corrosion-related equipment failures that could result in costly repairs or service delays. Some marine professionals report tool cost savings of 40-50% after implementing corrosion-proof storage solutions, demonstrating significant financial benefits over the cabinet’s lifespan.

Supporting Different Marine Applications

Marine workshops serve various applications including boat building, repair, maintenance, and refit operations, each with unique tool storage requirements. Corrosion-proof tool cabinets must accommodate these diverse needs through flexible configurations and specialized features. Boat building operations may need extensive storage for woodworking tools, marine-grade fasteners, and finishing equipment.

Different marine applications may require specialized storage for particular tools or equipment. Marine engine repair needs storage for specialized engine tools, diagnostic equipment, and precision instruments. Marine electrical work requires storage for corrosion-resistant wiring tools, testing equipment, and marine-grade electrical components. These specialized requirements highlight the need for versatile storage solutions that can adapt to various marine applications while maintaining corrosion resistance.

Integration with Marine Workflows

Marine work often follows specific sequences and procedures that benefit from organized tool storage aligned with natural workflow patterns. Tool storage systems should support various marine operations including hull repairs, engine servicing, electrical installations, and cosmetic work. The ability to access needed tools quickly without disrupting workflow enhances productivity and project completion times.

Workflow integration benefits extend to supporting various marine project types from routine maintenance to major refits. Some marine workshops implement tool organization systems that correspond to project phases or work sequences. This alignment enhances efficiency and reduces errors during complex marine projects. The ability to customize storage configurations based on specific marine workflows supports diverse operations and enhances overall productivity.

Technology Integration and Smart Features

Modern marine workshops increasingly incorporate technology to enhance efficiency and tool management. Marine tool cabinets can integrate with inventory management systems, maintenance scheduling software, and digital documentation platforms. This integration creates comprehensive tool management that supports modern marine operations and regulatory compliance.

Technology integration benefits extend to supporting advanced marine operations including predictive maintenance, digital documentation, and remote monitoring. Some marine tool cabinets incorporate IoT sensors that monitor environmental conditions, track tool usage, and alert staff to maintenance needs. These technological capabilities enhance marine workshop efficiency and support data-driven decision making for tool management and maintenance scheduling.

Environmental Considerations and Sustainability

Marine environments require special attention to environmental protection and sustainability. Marine tool cabinets should be constructed with environmentally friendly materials and manufacturing processes that minimize environmental impact. Some manufacturers incorporate recycled materials or sustainable production methods that align with marine conservation principles.

Environmental considerations extend to preventing tool contamination that could harm marine ecosystems. Proper tool storage prevents oil, grease, and other contaminants from reaching waterways during storage or transport. Some marine tool cabinets feature spill containment systems or drip trays that capture potential contaminants and protect marine environments. These environmental features support responsible marine operations and compliance with environmental regulations.

Future Trends in Marine Tool Storage

The evolution of marine tool storage continues with new materials, technologies, and design innovations. Advanced composite materials with superior corrosion resistance and reduced weight are emerging as alternatives to traditional metal construction. Smart storage systems with automated inventory management and predictive maintenance capabilities are becoming more sophisticated.

Future trends also include increased integration with marine management systems and digital documentation platforms. Some marine tool cabinets are incorporating renewable energy features such as solar-powered lighting or charging stations for cordless tools. These innovations promise to enhance marine workshop efficiency while supporting environmental sustainability and operational excellence.

Corrosion-proof tool cabinets represent essential investments for marine professionals working in challenging environments where standard storage solutions quickly fail. The combination of advanced materials, specialized construction, and thoughtful design features provides comprehensive protection for valuable tools while supporting efficient marine operations. By understanding the unique challenges of marine environments and selecting appropriate storage solutions, marine professionals can protect their tool investments, enhance operational efficiency, and maintain professional standards in their marine workshops. The right corrosion-proof tool cabinet becomes more than storage—it becomes a critical partner in marine operations, supporting success in demanding marine environments and protecting valuable investments for years to come.

Corrosion-proof tool cabinets represent essential investments for marine professionals working in challenging environments where standard storage solutions quickly fail. The combination of advanced materials, specialized construction, and thoughtful design features provides comprehensive protection for valuable tools while supporting efficient marine operations. By understanding the unique challenges of marine environments and selecting appropriate storage solutions, marine professionals can protect their tool investments, enhance operational efficiency, and maintain professional standards in their marine workshops. The right corrosion-proof tool cabinet becomes more than storage—it becomes a critical partner in marine operations, supporting success in demanding marine environments and protecting valuable investments for years to come.

Tags: Corrosion-Proof Tool Cabinets, Marine Workshops, Protect Your Investment