-

Sarah

Hi there! Welcome to my shop. Let me know if you have any questions.

Sarah

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

Aviation Tool Storage Solutions: Best Practices for Aircraft Maintenance Hangars

2025-11-05 13:46:44

Aircraft maintenance operations demand precision, organization, and strict adherence to safety standards, making tool storage systems critical components of hangar infrastructure. Aviation tool storage solutions must accommodate specialized tools, support regulatory compliance, and facilitate efficient maintenance workflows while ensuring tool accountability and FOD (Foreign Object Debris) prevention. This comprehensive guide explores best practices for aviation tool storage and their impact on maintenance efficiency and safety.

Aviation Industry Storage Requirements

Aircraft maintenance operates under stringent regulatory requirements including FAA, EASA, and military standards that govern tool control, documentation, and accountability. Aviation tool storage systems must support compliance with these regulations through systematic organization, comprehensive tracking, and secure storage. The ability to demonstrate proper tool control during inspections and audits represents a critical requirement.

The specialized nature of aviation tools requires storage solutions that accommodate various precision instruments, torque wrenches, and specialized aircraft maintenance equipment. Different aircraft types may require specific tool sets and storage configurations. Aviation tool cabinets must support these diverse requirements while maintaining consistent organization standards across all maintenance operations.

FOD Prevention and Tool Control

Foreign Object Debris prevention represents a critical safety concern in aviation maintenance where misplaced tools can cause catastrophic aircraft damage. Aviation tool storage systems must support comprehensive tool control programs through systematic organization, shadow boards, and accountability procedures. Every tool must have designated storage with clear visual indicators when items are missing.

Tool control benefits extend to supporting various maintenance procedures including pre-flight inspections, routine maintenance, and major repairs. Organized storage systems enable maintenance technicians to quickly verify tool completeness before and after maintenance tasks. Some aviation tool cabinets incorporate specialized features like foam cutouts, shadow boards, or tool silhouettes that enhance visual control and FOD prevention.

Specialized Aviation Tool Cabinet Features

Aviation-grade tool cabinets incorporate specialized features designed for aircraft maintenance environments. Stainless steel construction provides corrosion resistance and durability under hangar conditions. Sealed drawer mechanisms prevent contamination and protect precision tools from environmental factors. Some aviation cabinets feature climate-controlled compartments for sensitive instruments.

Security features support tool accountability through advanced locking mechanisms, access control systems, and comprehensive audit trails. Some aviation tool cabinets incorporate digital inventory management systems that track tool usage and availability. Integration with aircraft maintenance software enables seamless tool control documentation and regulatory compliance.

Supporting Different Aircraft Types

Various aircraft types require specialized tool sets and maintenance procedures, influencing storage requirements. Commercial aircraft maintenance may need extensive tool collections for various systems and components. Military aircraft maintenance often requires mission-specific tools and security protocols. General aviation maintenance typically requires more versatile, compact storage solutions.

Aviation tool storage systems must accommodate these diverse requirements through customizable configurations and modular designs. Some hangars implement standardized storage systems that can be adapted for different aircraft types while maintaining consistent organization principles. This adaptability supports maintenance operations serving diverse fleets or changing mission requirements.

Integration with Maintenance Operations

Aviation tool storage must integrate seamlessly with maintenance workflows and operational procedures. Storage systems should support various maintenance tasks including routine inspections, component repairs, and system overhauls. The ability to quickly access needed tools without disrupting maintenance procedures enhances efficiency and reduces aircraft downtime.

Integration benefits extend to supporting maintenance documentation and quality control procedures. Some aviation tool cabinets incorporate features that facilitate tool calibration tracking, maintenance scheduling, and usage documentation. These integration capabilities support comprehensive maintenance management and regulatory compliance.

Compliance with Aviation Standards

Aviation maintenance must comply with various standards including FAA Part 145, EASA Part 145, and military maintenance regulations. Tool storage systems support compliance through organized storage that facilitates proper documentation, tool tracking, and quality assurance procedures. The systematic arrangement enables maintenance organizations to demonstrate compliance during inspections and audits.

Compliance considerations extend to supporting various quality management systems including ISO 9001 and AS9100 for aerospace. Organized tool storage enables maintenance organizations to implement effective quality control measures and maintain the high standards required for aviation maintenance. These compliance features protect maintenance organizations from regulatory issues and support operational excellence.

Space Optimization in Hangar Environments

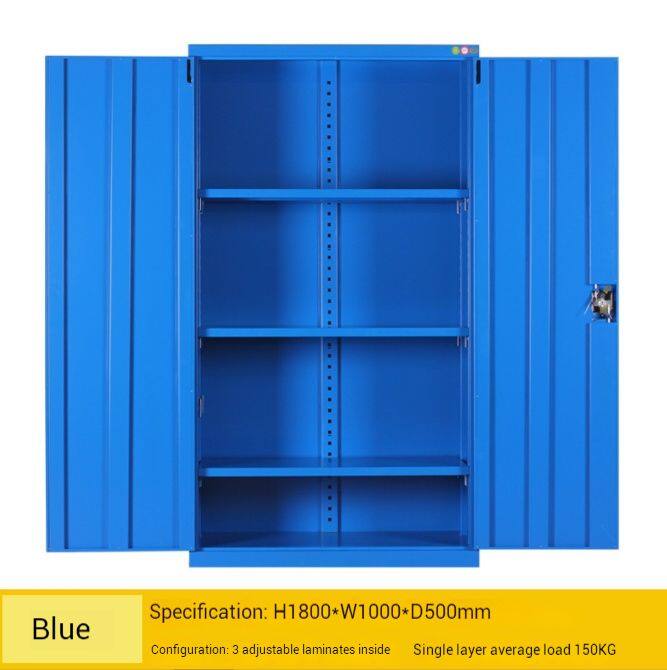

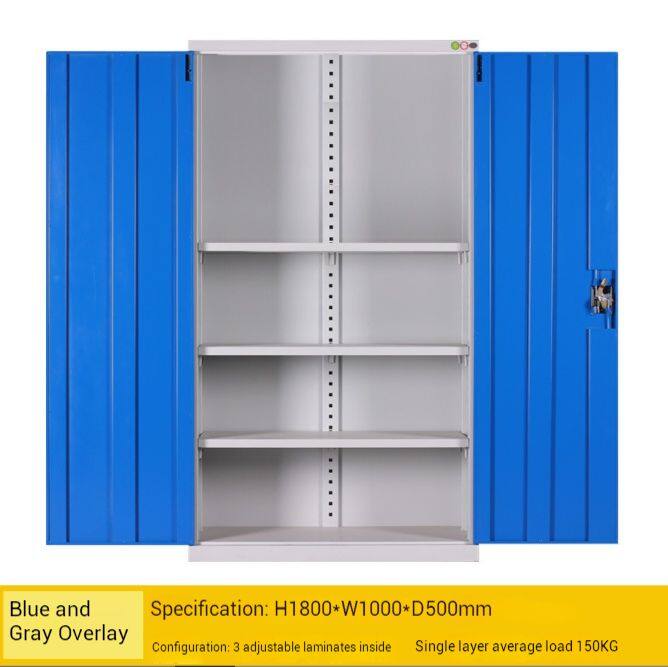

Aircraft hangars require efficient space utilization to accommodate various maintenance activities and aircraft types. Tool storage systems must maximize space efficiency while maintaining accessibility and supporting maintenance workflows. Vertical storage solutions, mobile cabinets, and specialized configurations optimize hangar space usage.

Space optimization benefits extend to supporting different maintenance scenarios from line maintenance to heavy maintenance checks. Some aviation tool cabinets feature compact designs that can be positioned close to work areas without interfering with aircraft movement. Mobile options provide flexibility to reposition storage as maintenance requirements change. These space-efficient designs enable hangars to accommodate more maintenance activities or larger aircraft.

Supporting Maintenance Safety

Aviation maintenance safety encompasses various considerations including tool handling, ergonomics, and workplace organization. Tool storage systems contribute to safety through ergonomic designs that reduce physical strain and prevent accidents. Proper tool organization prevents trip hazards and maintains clear work areas around aircraft.

Safety features include stable bases that prevent tip-over accidents, rounded corners that prevent injury, and appropriate weight distribution that facilitates safe tool handling. Some aviation tool cabinets incorporate specialized features like non-slip surfaces or integrated safety lighting that enhances visibility in hangar environments. These safety features protect maintenance personnel and aircraft during maintenance operations.

Technology Integration and Digital Management

Modern aviation maintenance increasingly incorporates digital technology and automated systems. Tool storage solutions can integrate with maintenance management software, inventory systems, and digital documentation platforms. This integration creates comprehensive tool management that supports modern maintenance operations and regulatory compliance.

Technology integration benefits extend to supporting advanced maintenance procedures including predictive maintenance and condition-based maintenance. Some aviation tool cabinets incorporate IoT sensors that monitor tool usage, calibration status, and maintenance requirements. These technological capabilities enhance maintenance efficiency and support data-driven decision making.

Cost-Effectiveness and Operational Efficiency

Aviation tool storage represents significant investment that must deliver value through enhanced maintenance efficiency, regulatory compliance, and safety improvements. The ability to reduce maintenance downtime through improved tool access directly impacts aircraft availability and operational costs. Proper tool control prevents FOD incidents that could result in costly aircraft damage.

The cost-effectiveness extends to supporting various business objectives including maintenance contract compliance, customer satisfaction, and competitive positioning. Organized tool storage enables maintenance organizations to demonstrate professionalism and capability that supports business development. The ability to maintain comprehensive tool control also reduces insurance costs and liability exposure.

Tags: Tool Storage, Aircraft Maintenance Hangars, Aviation Tool Storage Solutions