-

Sarah

Hi there! Welcome to my shop. Let me know if you have any questions.

Sarah

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

Mechanic’s Guide: Essential Tool Cabinet Setup for Auto Repair Shops

2025-11-05 13:40:55

Automotive repair shops thrive on efficiency, organization, and professional presentation. A well-organized tool cabinet system serves as the backbone of successful automotive operations, enabling mechanics to work more efficiently while protecting valuable tool investments. This comprehensive guide explores essential tool cabinet setup strategies that transform automotive repair operations and enhance service quality.

Understanding Automotive Tool Storage Requirements

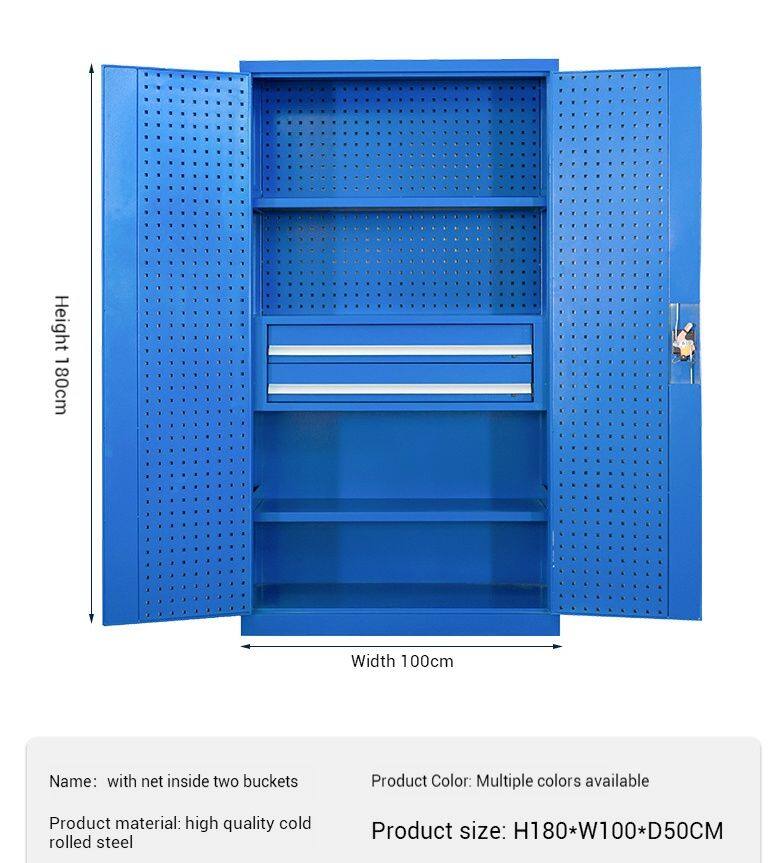

Automotive repair encompasses diverse tasks requiring specialized tools ranging from basic hand tools to advanced diagnostic equipment. Tool cabinets must accommodate various tool types including wrenches, sockets, pliers, diagnostic devices, and specialty automotive tools. The storage system must support both routine maintenance tasks and complex repair procedures while maintaining accessibility and organization.

Different automotive specialties may require unique storage configurations. General repair shops need versatile systems that handle various vehicle types and repair procedures. Specialty shops focusing on transmissions, engines, or electrical systems may require customized storage solutions tailored to their specific tool requirements and workflow patterns.

Essential Tool Cabinet Features for Automotive Applications

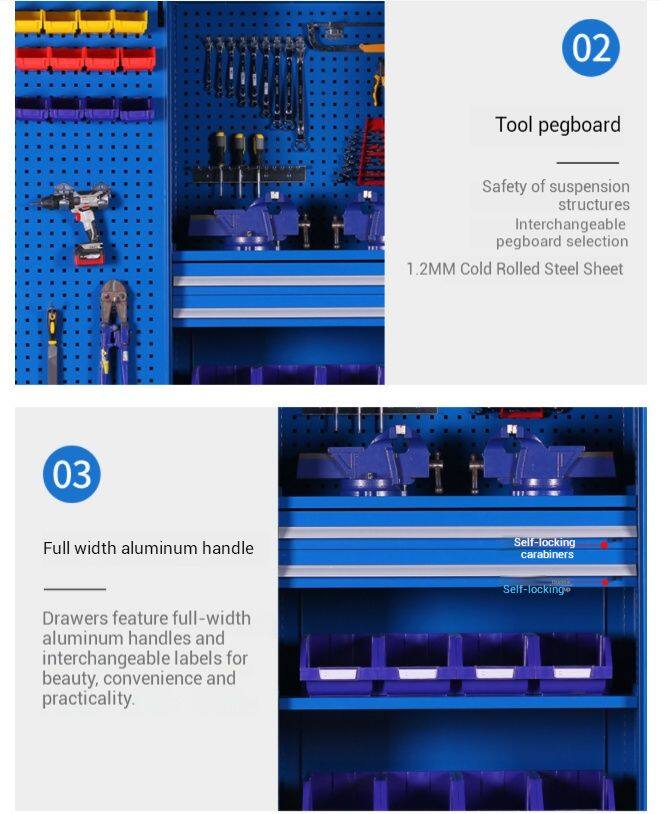

Automotive tool cabinets must withstand the demanding environment of repair shops where tools are frequently accessed, moved, and exposed to various substances. Heavy-duty construction with reinforced drawers and durable hardware ensures longevity under constant use. Drawer weight capacity becomes crucial for storing heavy automotive tools and equipment without compromising functionality.

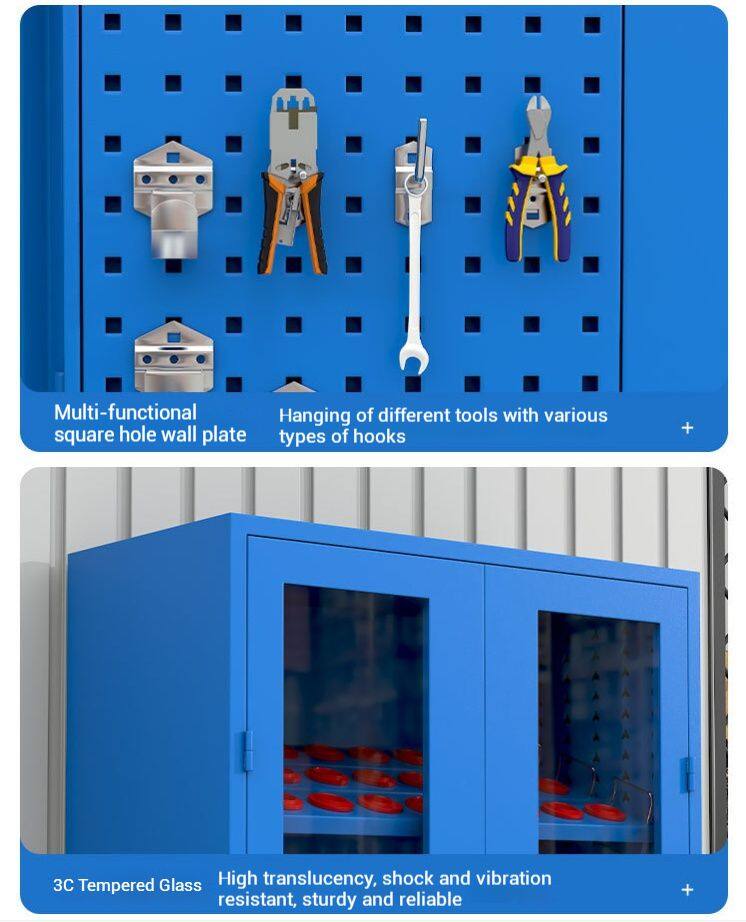

Security features protect valuable tool investments through robust locking mechanisms and tamper-resistant construction. Some automotive cabinets incorporate specialized features including built-in work surfaces, integrated lighting, and charging stations for cordless tools and diagnostic equipment. These features enhance functionality and support efficient repair operations.

Optimal Layout and Organization Strategies

Effective automotive tool cabinet organization begins with strategic layout planning. Place frequently used tools at waist to chest height for easy access without excessive bending or reaching. Group tools by function or task type to support natural workflow patterns during repair procedures. Consider the sequence of tool use during common repairs to optimize placement and minimize movement.

Labeling systems play a crucial role in maintaining organization over time. Clear, durable labels help mechanics quickly locate needed tools and ensure proper return to designated locations. Some shops implement color-coding systems to distinguish between different tool types or mechanic assignments. Visual organization techniques including shadow boards and foam cutouts enhance tool identification speed and accuracy.

Supporting Different Automotive Specialties

Different automotive specialties require tailored tool storage solutions. General repair shops benefit from versatile systems that accommodate various vehicle types and repair procedures. Transmission shops may need specialized storage for transmission tools, jacks, and heavy equipment. Electrical specialists require organized storage for diagnostic equipment, wiring tools, and testing devices.

Customization options allow automotive shops to configure cabinets according to their specific service offerings. Adjustable shelves, removable drawer dividers, and specialized compartments accommodate various tool sizes and types. Some automotive cabinets feature modular designs that can be reconfigured as service offerings expand or change over time.

Maximizing Space Efficiency in Auto Repair Shops

Auto repair shops often face space constraints that require efficient utilization of available area. Vertical storage solutions maximize space usage while maintaining accessibility. Mobile tool cabinets with heavy-duty casters provide flexibility to reposition workstations as needed. Corner cabinets and specialized configurations utilize otherwise wasted space effectively.

Multi-functional designs enhance space efficiency by combining storage with work surfaces. Some automotive cabinets incorporate fold-down work surfaces or integrated tool trays that provide additional workspace when needed. The ability to maximize space efficiency enables shops to accommodate more service bays or additional equipment without facility expansion.

Integration with Modern Automotive Technology

Modern automotive repair increasingly incorporates advanced diagnostic tools and equipment that require specialized storage considerations. Tool cabinets must accommodate charging stations for diagnostic tablets, storage for delicate electronic equipment, and organization for various adapters and connectors. Integration with shop management systems enables tool tracking and inventory management.

Some automotive tool cabinets feature built-in power management systems with surge protection and multiple outlet configurations. USB charging ports support modern diagnostic devices and mobile communication tools. Cable management systems keep cords organized and prevent trip hazards in busy shop environments. These technological integrations support modern automotive repair operations and enhance service capabilities.

Maintenance and Longevity Considerations

Automotive tool cabinets represent significant investments that require proper maintenance to ensure longevity and continued performance. Regular cleaning removes grease, oil, and debris that can damage drawer mechanisms and compromise functionality. Periodic inspection and tightening of hardware prevents loose components and ensures continued safe operation.

Drawer maintenance including lubrication of slides and mechanisms ensures smooth operation even under heavy loads. Surface care prevents rust and corrosion, particularly important in automotive environments where exposure to moisture and chemicals is common. Some automotive cabinets feature specialized coatings or materials that resist automotive chemicals and facilitate easy cleaning.

Enhancing Professional Image and Customer Confidence

Well-organized tool cabinets contribute significantly to automotive shop professionalism and customer confidence. Clean, organized workspaces create positive impressions and demonstrate attention to detail that extends to vehicle repairs. Customers often perceive organized shops as more professional and trustworthy, potentially influencing service decisions and customer loyalty.

Professional organization also supports accurate job costing and inventory management. When tools are properly organized and tracked, shops can more accurately account for tool usage and replacement needs. This organization supports business operations and contributes to overall profitability and success.

Tags: Mechanicu2019s Guide, Tool Cabinet Setup, Auto Repair Shops