-

Sarah

Hi there! Welcome to my shop. Let me know if you have any questions.

Sarah

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

Industrial Tool Cabinets for Manufacturing Plants: Boost Production Efficiency by 40%

2025-11-05 13:38:59

Industrial tool cabinets have emerged as critical infrastructure that can significantly enhance production efficiency by up to 40% through improved organization, reduced downtime, and streamlined workflows. This comprehensive guide explores how strategic tool cabinet implementation transforms manufacturing operations and delivers measurable productivity gains.

The Impact of Tool Organization on Production Efficiency

Manufacturing efficiency hinges on minimizing downtime and maximizing productive labor hours. Studies indicate that workers spend an average of 15-20 minutes daily searching for misplaced tools and equipment, translating to substantial productivity losses over time. Industrial tool cabinets address this challenge through systematic organization that enables quick tool identification and retrieval, reducing search time by up to 90%.

The efficiency gains extend beyond time savings to include improved workflow patterns and reduced worker frustration. Well-organized tool environments enable manufacturing teams to maintain focus on production tasks rather than tool management activities. This enhanced concentration leads to higher quality work, fewer errors, and increased overall production output without additional staffing requirements.

Key Features of High-Performance Industrial Tool Cabinets

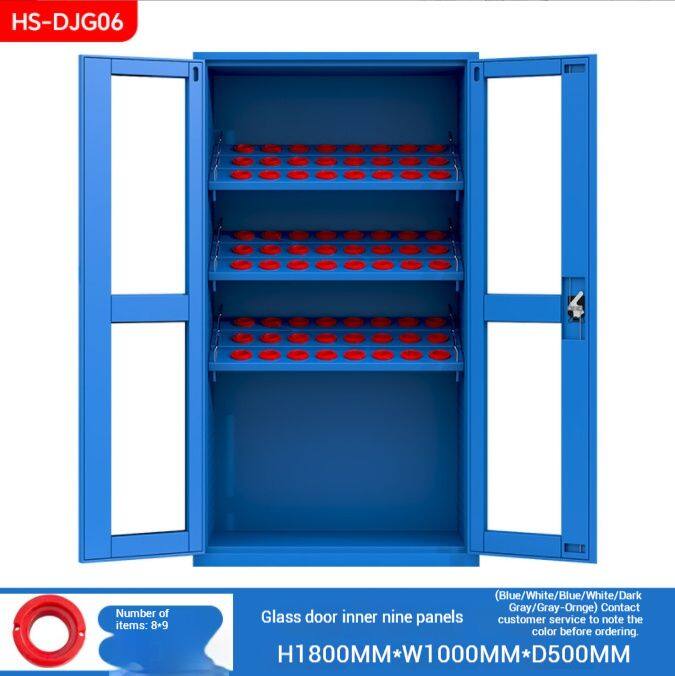

Modern industrial tool cabinets incorporate specialized features designed for demanding manufacturing environments. Heavy-duty steel construction with reinforced frames ensures durability under constant use, while ball-bearing drawer systems provide smooth operation even when fully loaded with heavy tools. Adjustable compartment systems allow customization based on specific manufacturing processes and tool requirements.

Advanced security features including centralized locking mechanisms and individual drawer locks protect valuable equipment and prevent unauthorized access. Ergonomic designs with appropriate handle placement and drawer depths reduce physical strain and enhance workplace safety. Some industrial cabinets incorporate integrated power strips and charging stations for cordless tools, further enhancing operational efficiency.

Implementing Tool Cabinet Systems in Manufacturing Environments

Successful implementation requires careful planning and consideration of specific manufacturing workflows. Begin by conducting a comprehensive tool inventory and usage analysis to determine optimal cabinet placement and configuration. Consider workflow patterns and place cabinets strategically to minimize movement between workstations and tool storage areas.

Employee training represents a critical component of successful implementation. Establish clear organization protocols and labeling systems that all team members understand and follow consistently. Regular maintenance schedules ensure continued optimal performance and longevity of tool cabinet systems. Some manufacturing facilities implement color-coding systems or shadow boards to enhance visual organization and tool identification speed.

Measuring ROI and Efficiency Gains

Manufacturing plants can quantify tool cabinet benefits through various metrics including reduced downtime, increased production output, and decreased tool replacement costs. Track time studies before and after implementation to measure search time reductions and productivity improvements. Monitor tool loss rates and replacement costs to assess financial impact.

Many manufacturers report payback periods of 6-12 months for industrial tool cabinet investments through efficiency gains and cost savings. Additional benefits include improved workplace safety, enhanced employee satisfaction, and stronger compliance with safety regulations. These intangible benefits contribute to overall operational excellence and competitive advantage.

Integration with Lean Manufacturing Principles

Industrial tool cabinets align perfectly with lean manufacturing methodologies by eliminating waste and optimizing workflows. The 5S methodology (Sort, Set in Order, Shine, Standardize, Sustain) particularly benefits from systematic tool organization. Visual management techniques including shadow boards and clear labeling support standardized work processes and continuous improvement initiatives.

Tool cabinet systems also support just-in-time manufacturing principles by ensuring tools are available when needed without excessive inventory. The systematic organization facilitates quick changeovers between different production runs, supporting flexible manufacturing capabilities and reducing setup times. This alignment with lean principles enhances overall manufacturing efficiency and competitiveness.

Future Trends in Industrial Tool Storage

The evolution of industrial tool cabinets continues with technological advancements and smart manufacturing integration. IoT-enabled cabinets with inventory tracking capabilities provide real-time data on tool usage and availability. Automated drawer systems and robotic integration further enhance efficiency in high-volume manufacturing environments.

Sustainability considerations are increasingly influencing industrial tool cabinet design, with manufacturers incorporating recycled materials and energy-efficient production processes. Modular designs that can be easily reconfigured as manufacturing needs evolve provide future-proofing capabilities and protect long-term investments.

Tags: Industrial Tool Cabinets, Manufacturing Plants, Boost Production Efficiency