The Benefits of Investing in High-Quality Tool Storage for Manufacturing Facilities

Manufacturing facilities operate in highly competitive environments where efficiency, productivity, and operational excellence determine success. Investing in high-quality tool storage solutions represents a strategic decision that delivers substantial returns across multiple operational dimensions. This comprehensive analysis explores the multifaceted benefits that premium tool storage systems bring to modern manufacturing operations.

Quantifying the Impact of Quality Tool Storage

Productivity Enhancement Metrics

Manufacturing facilities implementing high-quality tool storage solutions report significant measurable improvements:

| Performance Metric | Before Investment | After Investment | Improvement |

|---|---|---|---|

| Tool Retrieval Time | 4.2 minutes average | 45 seconds average | 82% reduction |

Production Downtime | 12% of shift time | 3% of shift time | 75% reduction |

Tool Replacement Costs | $1,200 monthly |$350 monthly | 71% reduction |

Workspace Efficiency | 65% utilization | 88% utilization | 35% increase |

Indirect Financial Benefits:

Enhanced employee satisfaction and retention

Improved safety record and reduced insurance costs

Better compliance with industry standards

Increased production capacity without additional labor

Operational Excellence Through Superior Organization

Streamlined Workflow Processes

High-quality tool storage systems transform manufacturing operations by:

Implementing 5S Methodology:

Sort: Eliminate unnecessary tools and equipment

Set in Order: Organize essential tools for maximum efficiency

Shine: Maintain clean, organized storage areas

Standardize: Create consistent organization protocols

Sustain: Maintain organization through continuous improvement

Facilitating Lean Manufacturing:

Reduced motion waste through strategic tool placement

Minimized waiting time with improved tool accessibility

Enhanced workflow continuity with mobile storage solutions

Optimized space utilization for maximum production efficiency

Enhanced Inventory Management

Sophisticated tool storage systems provide:

Real-Time Tracking Capabilities:

RFID integration for automated inventory monitoring

Barcode scanning for precise tool tracking

Digital check-in/check-out systems

Cloud-based inventory management platforms

Preventive Maintenance Integration:

Scheduled maintenance reminders for tools and equipment

Usage tracking for predictive maintenance planning

Calibration scheduling for precision instruments

Lifecycle management for tool replacement planning

Safety and Compliance Advantages

Workplace Safety Improvements

Investing in high-quality tool storage significantly enhances workplace safety:

Hazard Reduction:

Elimination of trip hazards from disorganized tools

Reduced risk of tool-related injuries

Improved ergonomics reducing strain injuries

Enhanced visibility and accessibility minimizing accidents

OSHA Compliance Enhancement:

Proper tool storage meeting regulatory requirements

Clear labeling and organization supporting safety protocols

Secure storage preventing unauthorized tool access

Documentation capabilities for safety audits

Industry Standard Compliance

Manufacturing facilities must maintain compliance with various industry standards:

ISO 9001 Quality Management:

Documented tool storage procedures

Consistent organization protocols

Regular audit capabilities

Continuous improvement processes

Aerospace and Automotive Standards:

AS9100 compliance for aerospace manufacturing

IATF 16949 requirements for automotive production

Tool control and calibration documentation

Traceability requirements for critical tools

Employee Productivity and Satisfaction

Enhancing Worker Efficiency

Quality tool storage directly impacts employee performance:

Time Optimization:

Reduced search time for required tools

Minimized interruptions during production processes

Streamlined tool changeover procedures

Improved workflow continuity

Ergonomic Benefits:

Reduced physical strain from proper tool organization

Height-adjustable storage accommodating different users

Easy-glide drawer systems minimizing effort

Anti-fatigue design features for extended use

Employee Satisfaction and Retention

Investing in high-quality tool storage demonstrates commitment to employee welfare:

Work Environment Improvement:

Professional, organized workspace appearance

Reduced frustration from tool disorganization

Enhanced sense of order and control

Improved morale through better working conditions

Retention Benefits:

Lower turnover rates due to improved working conditions

Enhanced employee engagement and satisfaction

Positive impact on company culture

Competitive advantage in talent acquisition

Long-Term Durability and Reliability

Construction Quality and Materials

Premium tool storage systems offer superior durability:

Material Specifications:

Heavy-gauge steel construction (14-12 gauge)

Industrial-grade powder coating finishes

Reinforced welding and joint construction

High-quality hardware and fasteners

Engineering Excellence:

Precision manufacturing tolerances

Advanced drawer slide systems

Robust locking mechanisms

Superior caster and mobility systems

Customization and Scalability

Customization and Scalability

Tailored Solutions for Specific Needs

High-quality tool storage systems offer extensive customization:

Industry-Specific Configurations:

Automotive manufacturing specialized layouts

Aerospace precision tool storage

Electronics manufacturing anti-static solutions

Heavy manufacturing industrial-grade systems

Modular Design Benefits:

Expandable systems growing with operations

Reconfigurable layouts adapting to changing needs

Interchangeable components for flexibility

Future-proof investment protection

Integration with Manufacturing Systems

Modern tool storage integrates seamlessly with existing infrastructure:

System Compatibility:

ERP system integration for inventory management

MES connectivity for production tracking

CMMS integration for maintenance management

IoT connectivity for smart manufacturing initiatives

Competitive Advantage Through Operational Excellence

Differentiation in the Marketplace

Manufacturing facilities with superior tool storage gain competitive advantages:

Quality Improvements:

Consistent tool availability supporting quality production

Reduced errors from proper tool selection and maintenance

Enhanced precision through organized tool storage

Improved product quality and consistency

Customer Satisfaction:

Faster turnaround times through improved efficiency

Enhanced quality control through organized processes

Reliable delivery schedules from optimized operations

Stronger reputation for operational excellence

Technology Integration and Future-Proofing

Smart Storage Solutions

Investing in high-quality tool storage prepares facilities for technological advancement:

IoT Integration:

Real-time tool usage monitoring

Predictive maintenance alerts

Automated inventory tracking

Data analytics for process optimization

Digital Transformation Support:

Cloud-based management systems

Mobile application integration

Automated reporting capabilities

Advanced analytics and insights

Recently Posted

-

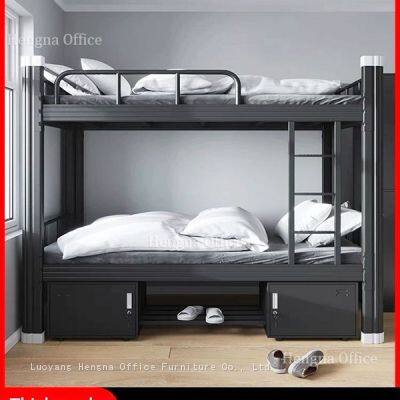

School Dorm Bunk Bed Buying Guide: Let Your Kids Sleep in Their Own Cozy Haven

December 30, 2025Selecting the perfect dormitory bed for schools is more than just picking a piece of furniture—it’s about creating a safe, comfort Read More

Read More -

Stop Smelly Mops! Why Your Facility Needs a Drainage-First Janitorial Cabinet

December 30, 2025Mops are essential tools in any facility, from hospitals to gyms, schools, and hotels. However, there's a dirty little se Read More

Read More -

Beyond the Bucket: Why Every Gym Needs a Dedicated Mop & Towel Drying Hub

December 30, 2025Maintaining a clean, hygienic gym is no longer optional—it’s essential for member safety, satisfaction, and retention. From spille Read More

Read More -

Messy Closet, Messy Business: Transforming Your Housekeeping Efficiency Overnight

December 30, 2025A disorganized housekeeping closet isn’t just an eyesore—it’s a productivity killer. In hotels, hospitals, and large facilities, j Read More

Read More