ABS vs. Metal Staff Lockers: Why Industrial Facilities in the US & EU Choose Plastic for Durability

In the demanding environment of modern factories and industrial facilities, the choice of staff lockers goes far beyond simple storage considerations. It impacts operational efficiency, maintenance costs, workplace safety, and long-term facility management. Over the past decade, a significant shift has occurred as industrial facilities across the United States and European Union increasingly prefer ABS (Acrylonitrile Butadiene Styrene) plastic staff lockers over traditional metal alternatives. This comprehensive analysis explores the compelling reasons behind this transition, focusing on the critical factors of durability and cost savings that drive facility managers’ decisions.

The Durability Advantage: ABS vs. Metal Lockers

Superior Impact Resistance

When it comes to withstanding the rigors of industrial environments, ABS plastic lockers demonstrate remarkable resilience:

Impact Absorption: ABS plastic possesses exceptional impact resistance, absorbing and dissipating force rather than denting or deforming like metal lockers. In factory settings where equipment movement and occasional collisions are common, this property proves invaluable.

Structural Integrity: Unlike metal lockers that may develop weak points at welds and joints over time, ABS lockers maintain their structural integrity through uniform material composition and advanced manufacturing techniques.

Temperature Tolerance: ABS plastic performs consistently across a wide temperature range (-40°C to 80°C), making it suitable for various industrial environments from cold storage facilities to manufacturing plants with high ambient temperatures.

Corrosion and Chemical Resistance

The industrial environment presents numerous challenges that can rapidly deteriorate traditional metal lockers:

Complete Corrosion Immunity: ABS plastic is completely immune to rust and corrosion, a significant advantage in facilities where moisture, chemicals, or cleaning agents are present. Metal lockers, even those with protective coatings, eventually succumb to corrosion in harsh industrial settings.

Chemical Resistance: ABS plastic resists degradation from common industrial chemicals, oils, solvents, and cleaning agents. This resistance ensures that lockers maintain their appearance and structural integrity even when exposed to substances that would quickly damage metal surfaces.

Moisture Performance: In facilities with high humidity or occasional water exposure, ABS lockers won’t swell, warp, or deteriorate like wood or corrode like metal alternatives.

The Financial Case: Cost Savings Over the Locker Lifecycle

Initial Investment vs. Long-Term Value

While the initial purchase price of ABS lockers may be comparable to or slightly higher than basic metal lockers, the total cost of ownership tells a different story:

Extended Service Life: Quality ABS lockers typically last 15-20 years in industrial environments, compared to 5-10 years for metal lockers that deteriorate due to corrosion and impact damage.

Reduced Replacement Frequency: The durability of ABS lockers means fewer replacements over time, reducing both material costs and the labor expenses associated with installation.

Minimal Maintenance Requirements: ABS lockers require significantly less maintenance than metal alternatives, translating to substantial savings in labor and materials over the locker’s lifespan.

Operational Efficiency Benefits

Beyond direct maintenance costs, ABS lockers contribute to operational efficiency in several ways:

Reduced Downtime: The durability of ABS lockers means fewer instances where lockers are out of service for repairs, ensuring consistent availability for staff.

Simplified Inventory Management: With longer service life and fewer replacements, facility managers can streamline their inventory and procurement processes.

Labor Optimization: Maintenance staff can redirect time spent on locker repairs to more critical facility maintenance tasks.

Safety and Hygiene Considerations

Enhanced Workplace Safety

ABS plastic lockers offer several safety advantages that align with modern industrial workplace standards:

No Sharp Edges: Unlike metal lockers that may develop sharp edges when dented or damaged, ABS lockers maintain smooth, safe surfaces even after impact.

Non-Conductive Material: ABS plastic eliminates electrical conductivity hazards, an important consideration in industrial environments where electrical safety is paramount.

Consistent Weight: ABS lockers maintain consistent weight regardless of age or condition, reducing the risk of tipping accidents that can occur with metal lockers as they deteriorate.

Hygiene and Cleanliness

In industrial settings where hygiene is increasingly important, ABS lockers provide distinct advantages:

Non-Porous Surface: The smooth, non-porous surface of ABS plastic resists bacterial growth and allows for thorough sanitization with standard cleaning agents.

Stain Resistance: ABS plastic resists staining from oils, grease, and other common industrial substances, maintaining a clean appearance with minimal effort.

Easy Decontamination: In facilities requiring periodic deep cleaning or decontamination, ABS lockers can be thoroughly sanitized without risk of material degradation.

Environmental and Sustainability Factors

Lifecycle Environmental Impact

Modern industrial facilities increasingly consider the environmental impact of their equipment choices:

Manufacturing Efficiency: The production process for ABS lockers typically requires less energy than metal locker manufacturing, resulting in a lower carbon footprint.

Recyclability: At the end of their service life, ABS lockers can be recycled and repurposed, supporting circular economy principles.

Reduced Resource Consumption: The extended lifespan of ABS lockers means fewer resources consumed over time for replacements and maintenance.

Compliance with Environmental Regulations

ABS lockers help facilities meet increasingly stringent environmental regulations:

No Harmful Coatings: Unlike metal lockers that may require protective coatings containing volatile organic compounds (VOCs), ABS lockers are manufactured without these potentially harmful substances.

Chemical-Free Maintenance: The absence of rust treatment requirements eliminates the need for chemical rust inhibitors that can pose environmental concerns.

Implementation Considerations for Industrial Facilities

Assessment and Planning

When transitioning from metal to ABS lockers, industrial facilities should consider:

Current Locker Condition: Evaluate the state of existing metal lockers to determine the urgency of replacement.

Budget Planning: Consider both initial investment and long-term savings when budgeting for locker replacement.

Phased Implementation: For large facilities, consider a phased approach to replacement to minimize disruption.

Customization Options

ABS lockers offer extensive customization possibilities for industrial applications:

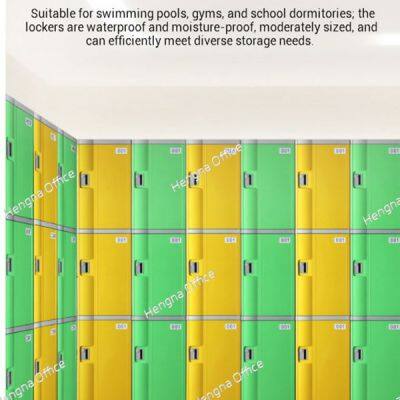

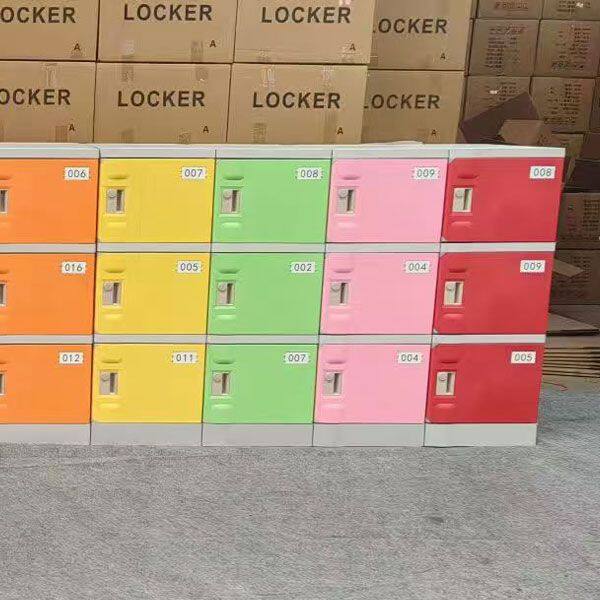

Size Configurations: Options to accommodate various space constraints and storage needs.

Color Coding: Different colors can designate departments, shifts, or security levels.

Locking Mechanisms: Choices ranging from simple key locks to advanced electronic access systems.

Ventilation Options: Enhanced ventilation for facilities storing work clothes or personal items that may generate odors.

The Clear Choice for Modern Industrial Facilities

The preference for ABS staff lockers over metal alternatives in US and European industrial facilities is not merely a trend but a well-founded decision based on comprehensive analysis of durability, cost savings, safety, and environmental factors. ABS lockers demonstrate superior performance in harsh industrial environments, offering exceptional resistance to impact, corrosion, and chemical exposure while requiring minimal maintenance.

The financial benefits extend far beyond the initial purchase price, with substantial savings in maintenance costs, reduced replacement frequency, and improved operational efficiency. When combined with the safety advantages and positive environmental impact, ABS plastic lockers represent the optimal choice for forward-thinking industrial facilities committed to providing durable, cost-effective storage solutions for their workforce.

As industrial facilities continue to evolve and face increasing pressure to optimize operations while ensuring workplace safety and sustainability, the adoption of ABS staff lockers stands as a clear example of how material innovation can deliver comprehensive benefits across multiple dimensions of facility management.

Recently Posted

-

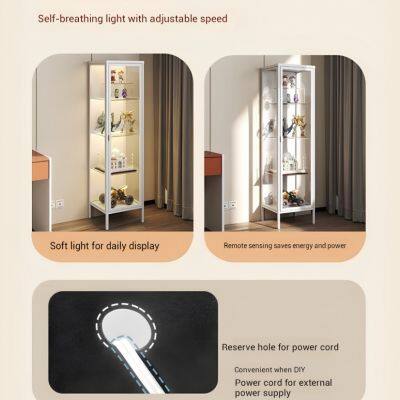

First Sight at the Entryway: How Sensor-Lit Display Cabinets Define Your Home’s Style

January 8, 2026They say you never get a second chance to make a first impression. In the world of interior design, the entryway (foyer) is the &q Read More

Read More -

Farewell to "Spider Webs": How Hidden Cable Management Holes Elevate Your Display Cabinet's Premium

January 8, 2026In the world of high-end collecting and retail display, there is a silent enemy that ruins even the most expensive setups: The Spi Read More

Read More -

Safety Beyond the Lock: Why 3C Tempered Glass, Rounded Corners, and Anti-Tip Kits Are Non-Negotiable

January 8, 2026When we think about "securing" a display cabinet, our minds immediately go to the lock. We think about protecting the co Read More

Read More -

How to Design a Safe and Sanitary Nursing Room in Public Spaces?

January 8, 2026The Business Case for Family-Friendly SpacesIn the modern commercial landscape, the quality of a facility is often judged by its m Read More

Read More