-

Sarah

Hi there! Welcome to my shop. Let me know if you have any questions.

Sarah

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

How to choose a PP Acid and Alkali Storage Cabinet for Safe Chemical Containment

2025-11-06 15:35:05

Why PP Storage Cabinets Matter for Chemical Safety

When it comes to laboratory and industrial chemical management, selecting the right PP acid and alkali storage cabinet is crucial for maintaining safety and compliance. Polypropylene (PP) storage cabinets have become the industry standard for corrosive chemical containment due to their exceptional chemical resistance and durability. Unlike traditional metal cabinets that can corrode or degrade when exposed to aggressive substances, PP cabinets provide long-lasting protection for both your chemicals and your facility. This comprehensive guide will walk you through the essential factors to consider when choosing the perfect storage solution for your specific needs.

Understanding Polypropylene Material Properties

What Makes PP Ideal for Chemical Storage?

Polypropylene is a thermoplastic polymer renowned for its outstanding chemical resistance properties. According to material science research, PP demonstrates excellent resistance to most acids, alkalis, and organic solvents12. This makes it particularly suitable for storing:

Strong acids (sulfuric acid, hydrochloric acid, nitric acid)

Alkalis and bases (sodium hydroxide, potassium hydroxide)

Salt solutions and oxidizing agents

Most organic solvents

The molecular structure of PP provides a non-polar surface that prevents chemical penetration and degradation, ensuring the cabinet maintains its structural integrity even with prolonged exposure to corrosive substances3.

Temperature Resistance and Environmental Factors

PP storage cabinets typically operate effectively within a temperature range of -30°C to +100°C, with some models capable of withstanding short-term exposure up to +140°C7. This thermal stability makes them suitable for various laboratory environments and storage conditions.

Key Selection Criteria for PP Acid and Alkali Storage Cabinets

1. Construction Quality and Design Features

When evaluating PP storage cabinets, consider these essential construction elements:

Material Thickness: Look for cabinets constructed from high-quality PP with adequate wall thickness (typically 5-10mm) to ensure structural integrity and chemical resistance.

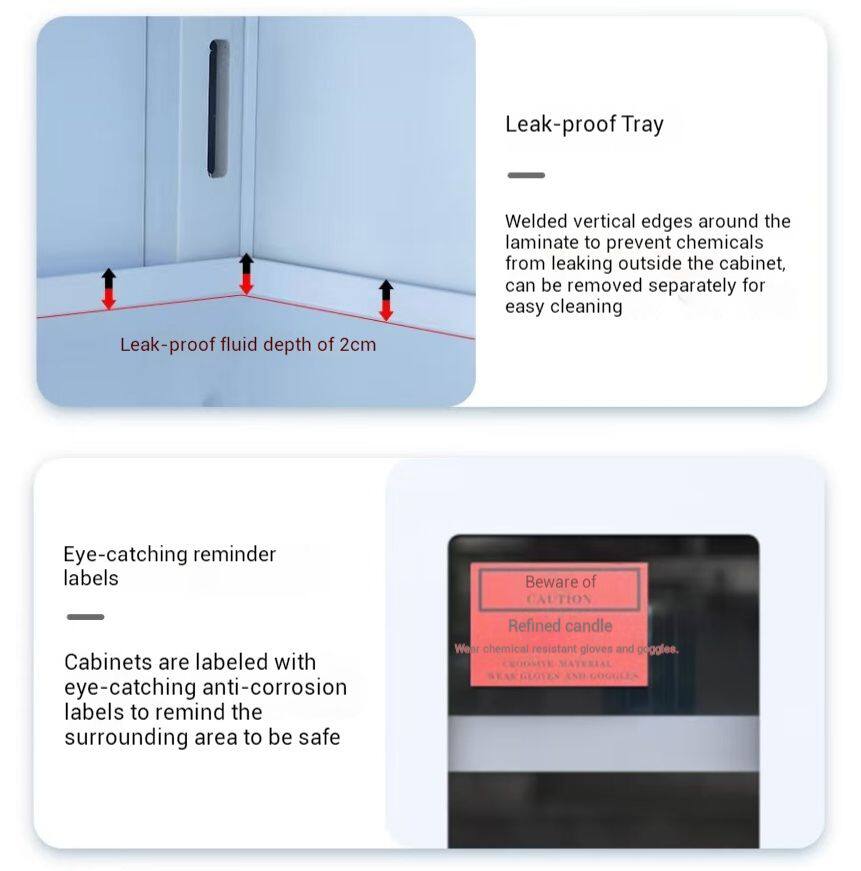

Seamless Design: Opt for cabinets with seamless or fully welded construction to prevent chemical leakage at joints and seams. This design feature eliminates potential weak points where chemicals could accumulate or cause degradation9.

Ventilation System: Proper ventilation is critical for safe chemical storage. Quality PP cabinets should include:

Built-in ventilation ports with flame arresters

Optional ducting capabilities for external ventilation

Adjustable air flow controls for different chemical types

2. Storage Capacity and Configuration

Size Requirements: Evaluate your storage needs based on:

Current chemical inventory

Future expansion plans

Container sizes and types

Available laboratory space

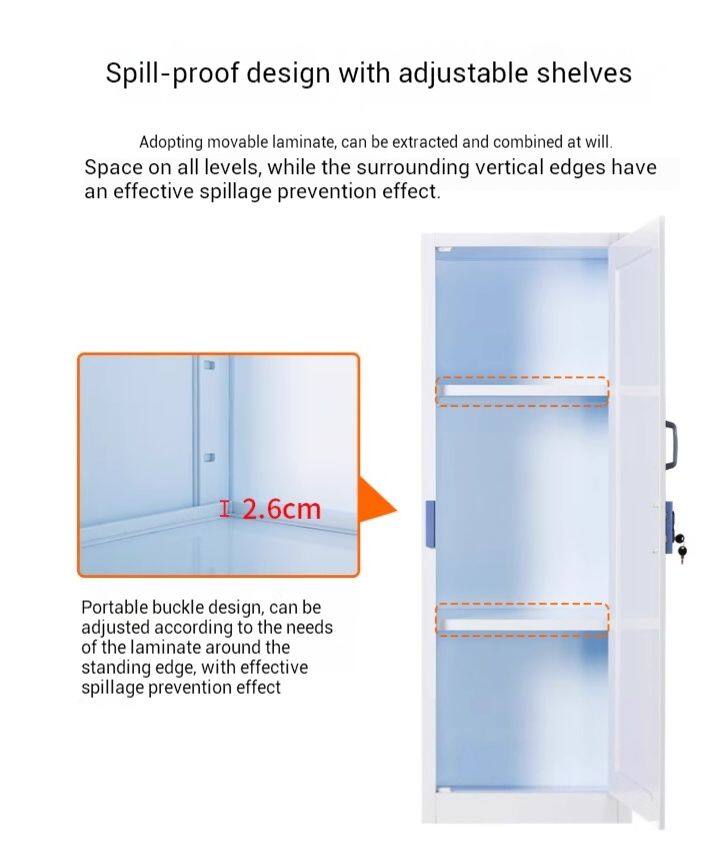

Compartment Design: Consider cabinets with:

Separate compartments for acids and alkalis

Adjustable shelving systems

Spill containment trays with minimum 2-inch depth

Load-bearing capacity of at least 150 pounds per shelf28

3. Safety and Compliance Features

Regulatory Compliance: Ensure your chosen cabinet meets these standards:

OSHA 29 CFR 1910.106 for flammable and combustible liquids

EPA regulations for chemical storage

Local fire and safety codes

ISO 9001 quality management certification9

Safety Features: Look for:

Three-point locking mechanisms with manual override

Self-closing doors with magnetic latches

Grounding provisions for static dissipation

Leak-proof secondary containment systems

Chemical Compatibility and Storage Guidelines

Proper Chemical Segregation

One of the most critical aspects of chemical storage is proper segregation. Never store incompatible chemicals together, even in a high-quality PP cabinet. Follow these guidelines:

| Chemical Type | Storage Requirements | Incompatible Substances |

|---|---|---|

| Strong Acids | Separate compartment, secondary containment | Bases, oxidizers, flammables |

| Strong Bases | Separate compartment, ventilation | Acids, oxidizers, metals |

| Oxidizers | Cool, dry location, separate from organics | Flammables, reducing agents |

| Flammables | Flame-resistant cabinet, grounding | Oxidizers, acids |

Container and Labeling Requirements

Use only compatible containers (PP, HDPE, or glass)

Ensure all containers are properly labeled with chemical name, concentration, and hazard warnings

Implement a first-in, first-out (FIFO) inventory system

Regularly inspect containers for damage or deterioration14

Installation and Maintenance Considerations

Proper Installation Guidelines

Location Selection: Choose a location that:

Is away from direct sunlight and heat sources

Provides adequate ventilation

Allows for easy access and emergency response

Meets local building and fire codes

Cabinet Placement: Ensure:

Level placement on a stable surface

Adequate clearance for door operation (minimum 180° opening)

Proper anchoring if required by local regulations

Access to emergency equipment (eyewash stations, safety showers)

Regular Maintenance Procedures

Implement a maintenance schedule that includes:

Daily Checks:

Visual inspection for leaks or damage

Verification of proper door closure

Monitoring of ventilation systems

Monthly Inspections:

Detailed examination of seals and gaskets

Testing of locking mechanisms

Cleaning of interior surfaces with compatible cleaners

Annual Professional Service:

Comprehensive structural inspection

Ventilation system performance testing

Recertification of safety features

Cost Considerations and ROI Analysis

Initial Investment vs. Long-term Value

While PP storage cabinets may represent a higher initial investment compared to traditional metal cabinets, they offer significant long-term benefits:

Durability: PP cabinets typically last 15-20 years with proper maintenance, compared to 5-10 years for metal cabinets in corrosive environments9.

Reduced Replacement Costs: The corrosion-resistant nature of PP eliminates the need for frequent replacement due to chemical damage.

Safety Benefits: Proper chemical storage reduces the risk of accidents, spills, and regulatory violations, potentially saving thousands in potential fines and cleanup costs.

Total Cost of Ownership Analysis

| Cost Factor | PP Cabinet | Metal Cabinet |

|---|---|---|

| Initial Purchase | $2,000-$5,000 | $1,500-$3,500 |

| Expected Lifespan | 15-20 years | 5-10 years |

| Maintenance Costs | Low | Moderate to High |

| Replacement Frequency | Low | High |

| Compliance Risk | Low | Moderate |

Making the Final Decision: A Step-by-Step Selection Process

Step 1: Assess Your Specific Needs

Inventory all chemicals requiring storage

Categorize by hazard type and compatibility

Determine storage volume requirements

Identify space constraints and installation requirements

Step 2: Research and Compare Options

Evaluate multiple manufacturers and models

Request product specifications and compliance documentation

Compare features and warranties

Seek references and customer reviews

Step 3: Verify Compliance and Certification

Confirm regulatory compliance for your jurisdiction

Review safety certifications and testing reports

Validate warranty and service agreements

Ensure availability of replacement parts

Step 4: Plan for Installation and Training

Schedule professional installation if required

Train staff on proper usage and maintenance procedures

Establish emergency response protocols

Implement regular inspection schedules

Choosing the right PP acid and alkali storage cabinet is a critical decision that impacts laboratory safety, regulatory compliance, and operational efficiency. By considering the factors outlined in this guide—material properties, construction quality, safety features, and maintenance requirements—you can select a storage solution that provides reliable protection for your chemicals and personnel.

Remember that the cheapest option is not always the most cost-effective in the long run. Investing in a high-quality PP storage cabinet from a reputable manufacturer ensures peace of mind and protects your facility from the potentially devastating consequences of improper chemical storage.

For specific recommendations based on your unique requirements, consult with chemical storage specialists who can provide tailored solutions for your laboratory or industrial facility. The right investment today in proper chemical storage equipment will pay dividends in safety, compliance, and operational efficiency for years to come.

About the Author: This comprehensive guide was developed to help laboratory managers, safety officers, and facility managers make informed decisions about chemical storage solutions. For more information on PP acid and alkali storage cabinets or to request a consultation, contact our chemical storage specialists today.

Tags: Chemical storage cabinet, PP Acid and Alkali Storage Cabinet, Storage Cabinet for Safe Chemical Containment