-

Sarah

Hi there! Welcome to my shop. Let me know if you have any questions.

Sarah

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

Warehouse Organization: Tool Cabinet Systems for Efficient Inventory Management

2025-11-05 14:00:41

Warehouse operations depend heavily on efficient tool management and inventory control to maintain productivity, reduce downtime, and support various operational requirements. Tool cabinet systems designed specifically for warehouse environments play crucial roles in organizing maintenance tools, supporting repair operations, and facilitating efficient inventory management. This comprehensive guide explores warehouse tool storage solutions and their impact on operational efficiency and inventory control.

Warehouse Tool Management Challenges

Warehouses face unique tool management challenges including multiple maintenance teams, various tool types, and distributed work areas across large facilities. The need to track tool usage, prevent loss, and maintain availability for maintenance tasks requires systematic organization and control. Warehouse tool cabinets must address these challenges while supporting efficient maintenance operations and minimizing equipment downtime.

Tool management challenges extend to supporting various warehouse operations including equipment repair, facility maintenance, and inventory management. Different maintenance tasks may require specialized tools and equipment that must be readily available when needed. Warehouse tool storage systems must accommodate these diverse requirements while maintaining organization and accessibility across large facilities.

Centralized vs. Distributed Tool Storage

Warehouses must decide between centralized tool storage locations or distributed systems placed throughout the facility. Centralized storage offers better control and security but may require more travel time for maintenance teams. Distributed storage provides convenient access but requires more sophisticated tracking and management systems.

Storage strategy considerations include warehouse layout, maintenance team organization, and tool usage patterns. Some warehouses implement hybrid systems with centralized storage for specialized tools and distributed storage for frequently used items. Tool cabinet systems can be configured to support various storage strategies while maintaining consistent organization and tracking standards across the facility.

Inventory Tracking and Management Systems

Modern warehouse operations utilize sophisticated inventory management systems that track tool usage, maintenance schedules, and availability. Tool storage solutions should integrate with these systems through barcode scanning, RFID technology, or digital inventory management. This integration creates comprehensive tool management that supports warehouse efficiency and cost control.

Inventory management benefits extend to supporting various warehouse operations including preventive maintenance, equipment repair, and tool replacement planning. Some warehouse tool cabinets incorporate automated tracking that alerts staff when tools require maintenance or replacement. These integration capabilities enhance warehouse efficiency and support data-driven decision making for tool management.

Supporting Maintenance Operations

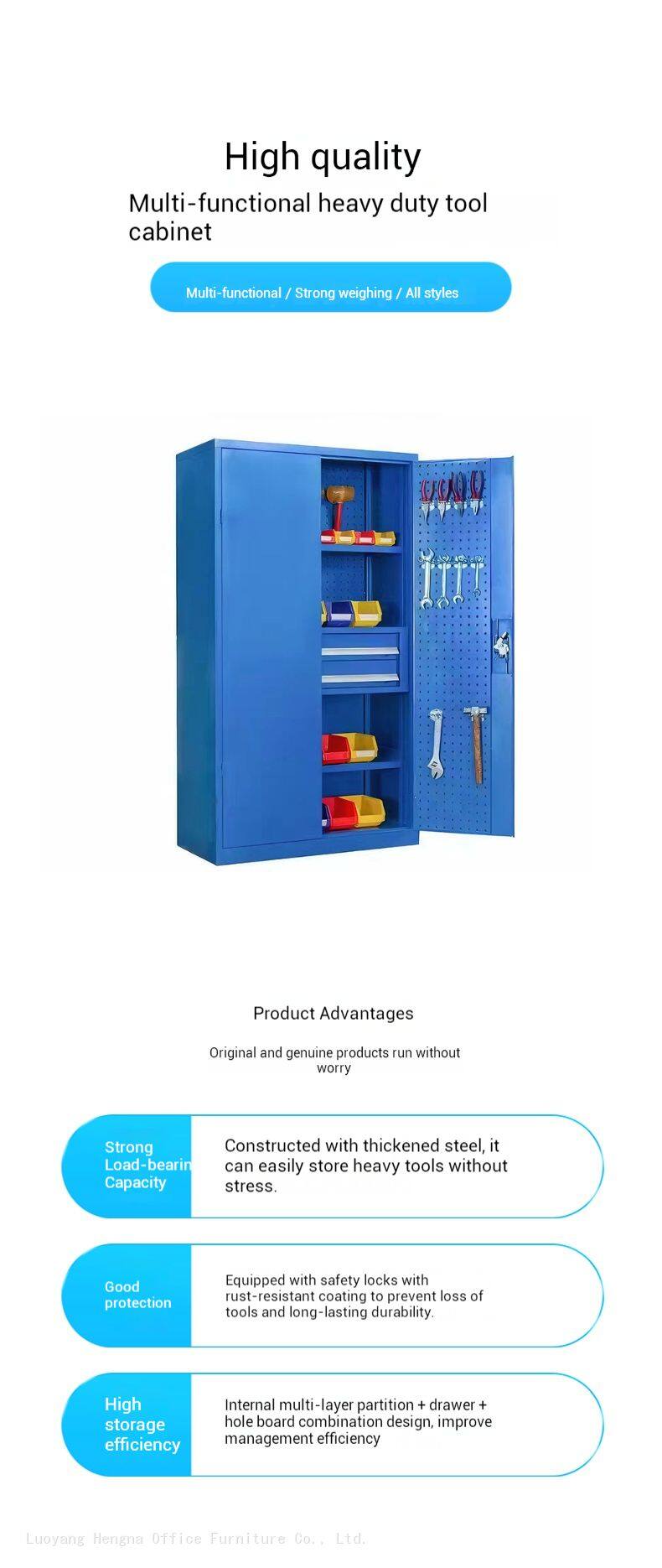

Warehouse maintenance encompasses various activities including equipment repair, facility upkeep, and preventive maintenance programs. Tool storage systems should support these diverse maintenance requirements through organized storage that enables quick access to needed tools and equipment. Some cabinets feature specialized compartments for frequently used maintenance items and quick-access areas for emergency repairs.

Maintenance support benefits extend to supporting various maintenance team structures and work schedules. Organized tool storage enables maintenance teams to work efficiently regardless of team size or experience level. Some warehouse tool cabinets incorporate color-coding or labeling systems that correspond to different maintenance specialties or team assignments. These organization features enhance maintenance efficiency and reduce equipment downtime.

Security and Loss Prevention

Warehouse tools represent significant investments that require protection from theft and unauthorized use. Tool storage systems should incorporate security features including locking mechanisms, access control, and monitoring systems. Some warehouses implement tool accountability programs that track individual tool usage and responsibility.

Security considerations extend to supporting various warehouse security protocols and access control systems. Tool cabinets can be integrated with warehouse security networks to provide comprehensive monitoring and control. Some systems feature audit trails that record tool access and usage patterns, supporting security investigations and loss prevention efforts. These security features protect valuable tool investments and support warehouse security programs.

Space Optimization in Warehouse Environments

Warehouses require efficient space utilization to maximize storage capacity and operational efficiency. Tool storage systems should optimize space usage while maintaining accessibility and supporting maintenance workflows. Vertical storage solutions, mobile cabinets, and specialized configurations enhance space efficiency in warehouse environments.

Space optimization benefits extend to supporting various warehouse layouts and operational requirements. Some warehouses implement tool storage systems that can be reconfigured as operational needs change or warehouse layouts evolve. Mobile tool cabinets provide flexibility to position storage where needed while maintaining organization and security. These space-efficient designs enable warehouses to maximize operational capacity without facility expansion.

Supporting Different Warehouse Types

Various warehouse types including distribution centers, manufacturing facilities, and cold storage warehouses have different tool storage requirements. Distribution centers may need versatile storage for various maintenance tasks. Manufacturing facilities might require specialized storage for production equipment tools. Cold storage warehouses need storage that can operate in low-temperature environments.

Warehouse type considerations extend to supporting various operational requirements and environmental conditions. Tool cabinet systems can be customized with specialized features that address specific warehouse types while maintaining core organizational principles. This adaptability enables warehouses to standardize on storage solutions while meeting diverse operational requirements.

Integration with Warehouse Management Systems

Modern warehouses utilize sophisticated management systems for inventory control, equipment tracking, and operational planning. Tool storage solutions should integrate with these systems to provide comprehensive tool management that supports overall warehouse operations. Integration capabilities include data synchronization, automated reporting, and predictive maintenance scheduling.

System integration benefits extend to supporting various warehouse technologies including automated material handling, robotics, and IoT devices. Some tool cabinets incorporate smart features that communicate with warehouse management systems to provide real-time tool availability and usage data. These integration capabilities enhance warehouse efficiency and support advanced warehouse operations.

Durability and Long-Term Performance

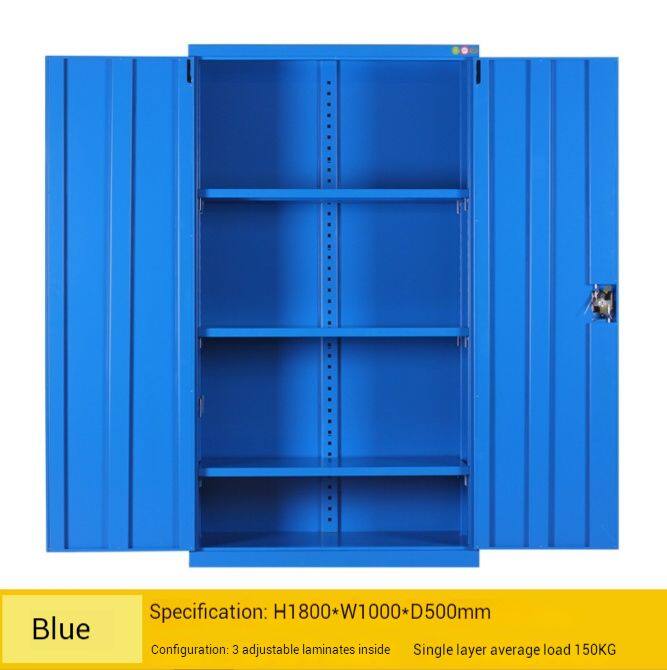

Warehouse environments can be demanding with constant use, heavy loads, and various environmental factors. Tool storage systems must be constructed with durable materials and robust designs that withstand warehouse conditions. Heavy-duty steel construction, reinforced drawers, and industrial-grade hardware ensure longevity under constant use.

Durability considerations extend to supporting various warehouse environmental conditions including temperature fluctuations, humidity, and potential chemical exposure. Some warehouse tool cabinets feature specialized coatings or materials that resist warehouse environmental factors. These durability features ensure long-term performance and protect tool investments in demanding warehouse environments.

Cost-Effectiveness and ROI Analysis

Warehouse tool storage represents significant investment that must deliver measurable returns through improved efficiency, reduced tool loss, and enhanced maintenance operations. The ability to reduce equipment downtime through improved tool access directly impacts warehouse productivity and operational costs. Proper tool organization prevents tool loss and reduces replacement expenses.

ROI considerations extend to supporting various warehouse objectives including operational efficiency, cost control, and service quality. Organized tool storage enables warehouses to improve maintenance response times, reduce equipment failures, and enhance overall operational performance. Some warehouses report tool cost savings of 25-35% after implementing organized storage systems, demonstrating significant financial benefits.

Tags: Warehouse Organization, Tool Cabinet Systems, Efficient Inventory Management