-

Sarah

Hi there! Welcome to my shop. Let me know if you have any questions.

Sarah

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

Optimize Kitchen Storage with NSF-Certified Steel Shelving Solutions

2025-11-02 13:55:14

Commercial kitchens and food service operations require storage solutions that meet stringent safety standards while maintaining efficiency and organization. NSF-certified steel shelving has become the industry standard for food storage, offering the durability, hygiene, and compliance necessary for professional kitchen environments. This comprehensive guide explores how certified steel shelving systems can optimize kitchen storage while ensuring food safety and operational efficiency.

Understanding NSF Certification Requirements

NSF International certification represents the gold standard for food service equipment, ensuring products meet strict public health and safety requirements. For steel shelving systems, NSF certification involves rigorous testing for materials safety, structural integrity, cleanability, and overall design suitability for food storage environments. Certified shelving must use food-grade materials that won’t contaminate stored items or harbor bacteria.

The certification process evaluates shelving design for ease of cleaning, with particular attention to corners, joints, and surfaces where food particles or moisture might accumulate. NSF-certified steel shelving features smooth, non-porous surfaces that resist bacterial growth and can be thoroughly sanitized. This certification provides kitchen managers and health inspectors with confidence that storage systems meet or exceed food safety requirements.

Material Construction and Hygiene Benefits

NSF-certified steel shelving typically features 304 stainless steel construction with specialized finishes that enhance durability and hygiene. The non-porous surface prevents bacterial absorption and allows for thorough cleaning and sanitization between uses. Unlike wood or plastic alternatives that may scratch, warp, or absorb odors, steel maintains its integrity even under rigorous cleaning protocols.

The material construction resists corrosion from acidic foods, cleaning chemicals, and moisture exposure common in kitchen environments. Some manufacturers incorporate antimicrobial coatings that provide additional protection against bacterial growth. These hygiene features make steel shelving ideal for storing food items at various temperature ranges while maintaining safety standards.

Weight Capacity and Food Storage Applications

Commercial kitchens store diverse food items ranging from lightweight dry goods to heavy bulk ingredients and canned products. NSF-certified steel shelving systems offer substantial weight capacities, typically ranging from 300 to 800 pounds per shelf, accommodating various food storage requirements. This capacity allows kitchens to maximize vertical space while maintaining safe storage practices.

Different food types require specialized storage considerations that steel shelving can address through customizable configurations. Dry storage areas benefit from adjustable shelf heights for various container sizes. Refrigerated storage requires shelving that maintains structural integrity in cold temperatures while allowing proper air circulation. Hot food holding areas need heat-resistant materials that won’t degrade under elevated temperatures.

Customization Options for Kitchen Layouts

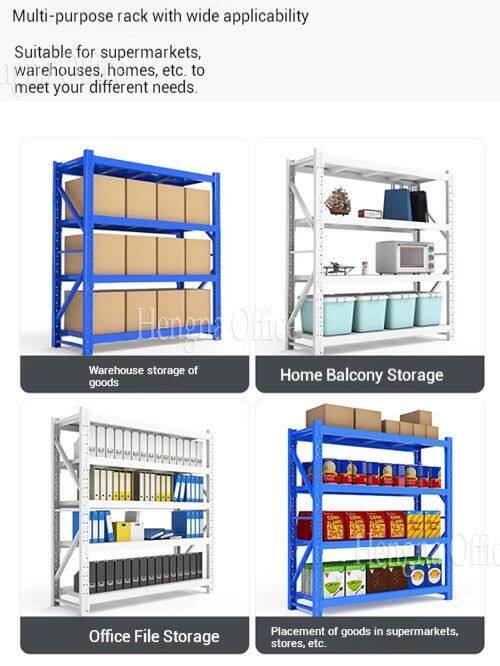

Commercial kitchen layouts vary significantly based on operation type, space constraints, and workflow requirements. NSF-certified steel shelving systems offer extensive customization options to optimize storage within specific kitchen configurations. Wall-mounted units maximize floor space while keeping frequently used items accessible. Freestanding systems provide flexibility for larger storage needs and reconfigurable layouts.

Specialized configurations include corner units that utilize otherwise wasted space, mobile units with casters for flexible positioning, and undershelf baskets for additional storage capacity. Some manufacturers offer custom fabrication services to create shelving solutions that perfectly match unique kitchen dimensions and requirements. This customization capability ensures optimal space utilization regardless of kitchen size or layout.

Temperature Resistance and Refrigeration Applications

Commercial kitchens often require storage solutions that can operate across various temperature ranges, from freezers to hot holding areas. NSF-certified steel shelving maintains structural integrity and hygiene standards across these temperature extremes. Cold storage applications require materials that won’t become brittle or corrode in freezing temperatures, while hot storage needs heat resistance and stability.

Steel shelving systems designed for refrigeration often feature specialized coatings that resist moisture and prevent ice buildup. Proper air circulation is crucial for refrigerated storage, and steel shelving designs typically incorporate vented shelves or spacing that allows cold air to flow freely around stored items. This temperature versatility makes steel shelving suitable for walk-in coolers, freezers, and hot food holding areas.

Cleaning and Maintenance Protocols

Maintaining hygiene in commercial kitchens requires rigorous cleaning protocols that storage systems must withstand without degradation. NSF-certified steel shelving facilitates effective cleaning through smooth surfaces, rounded corners, and minimal crevices where food particles might accumulate. The material resistance to harsh cleaning chemicals allows for thorough sanitization without damage.

Regular maintenance procedures include daily cleaning with food-safe sanitizers, weekly deep cleaning, and periodic inspection for damage or wear. Steel shelving systems typically require minimal maintenance beyond routine cleaning, with no need for painting, sealing, or special treatments. This durability reduces maintenance costs and minimizes downtime during cleaning procedures.

Compliance with Health Department Regulations

Health department inspections represent critical considerations for food service operations, and storage systems play significant roles in compliance outcomes. NSF-certified steel shelving meets or exceeds most health department requirements for food storage, including material safety, cleanability, and structural integrity. The certification provides documented evidence of compliance during inspections.

Beyond basic certification, steel shelving systems support compliance through features such as off-floor mounting that facilitates cleaning underneath, smooth surfaces that prevent pest harborage, and corrosion resistance that maintains hygiene over time. These features help kitchens achieve and maintain high health inspection scores while protecting public health.

Installation and Space Planning

Proper installation of steel shelving systems is crucial for maximizing kitchen efficiency and maintaining safety standards. Professional installation ensures proper anchoring, level assembly, and compliance with local building codes. Space planning considerations include workflow optimization, accessibility requirements, and clearance for cleaning and maintenance.

Kitchen layout planning should incorporate storage zones based on food types and usage patterns. Steel shelving systems can be configured to create designated areas for dry storage, refrigerated items, and cleaning supplies. Proper spacing between units allows for easy cleaning and prevents cross-contamination risks. Professional kitchen designers often collaborate with shelving manufacturers to create optimal storage solutions.

Cost Analysis and Operational Benefits

Investing in NSF-certified steel shelving delivers substantial returns through improved food safety, operational efficiency, and compliance assurance. While initial costs may exceed those of non-certified alternatives, the long-term benefits include reduced health code violations, decreased food waste from improved storage conditions, and enhanced staff productivity.

The durability of steel construction provides excellent long-term value, with many systems lasting 20+ years even in demanding kitchen environments. Reduced replacement frequency and minimal maintenance requirements lower total cost of ownership. Improved organization and accessibility can reduce labor costs associated with inventory management and food preparation. These factors combine to deliver compelling financial returns for food service operations.

Future Trends in Commercial Kitchen Storage

The commercial kitchen industry continues to evolve, and steel shelving systems are adapting to incorporate new technologies and features. Smart shelving solutions with integrated temperature monitoring, inventory tracking, and automated ordering systems enhance kitchen efficiency. Modular designs that can be easily reconfigured support changing menu items and operational needs.

Sustainability considerations are increasingly influencing kitchen equipment decisions, with manufacturers incorporating recycled materials and energy-efficient production processes. Ergonomic designs that reduce physical strain on kitchen staff improve working conditions and productivity. These innovations ensure that steel shelving will continue to meet evolving commercial kitchen needs while adapting to new technologies and operational requirements.

NSF-certified steel shelving systems represent essential investments for commercial kitchens seeking to optimize storage while maintaining food safety standards. The combination of hygiene features, durability, and customization options makes steel shelving the ideal choice for diverse food service applications. By understanding certification requirements, installation considerations, and maintenance protocols, kitchen operators can create storage solutions that enhance efficiency, ensure compliance, and protect public health. As commercial kitchens continue to evolve, steel shelving systems will remain fundamental to effective food storage and operational success.

Tags: Steel Shelving Solutions, Optimize Kitchen Storage