-

Sarah

Hi there! Welcome to my shop. Let me know if you have any questions.

Sarah

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

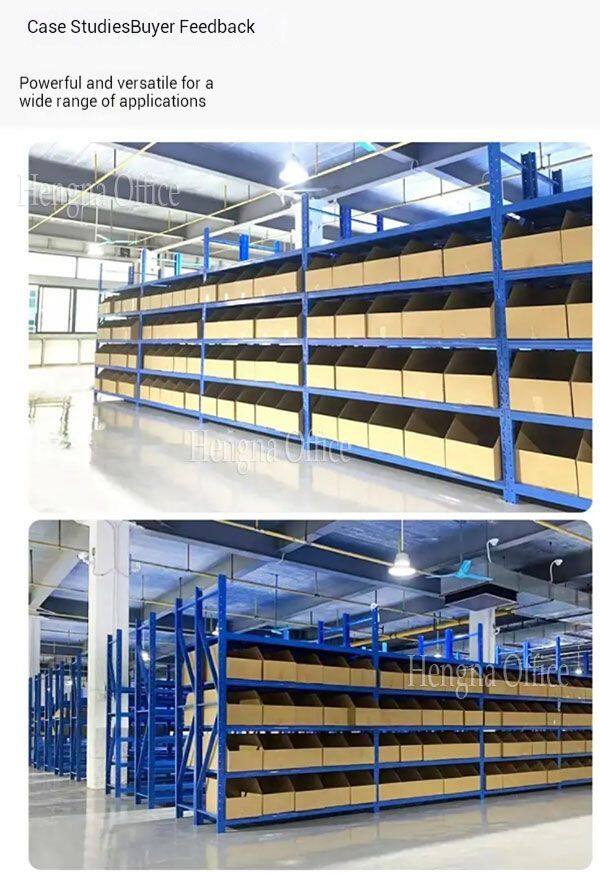

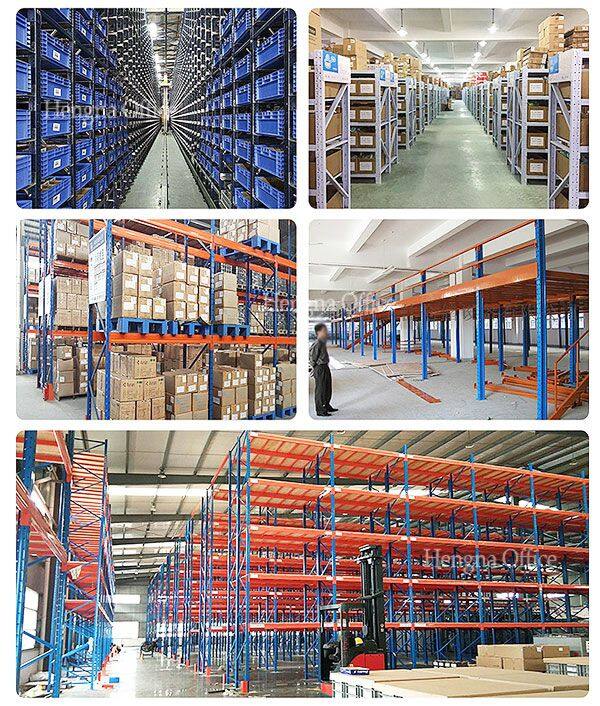

Maximize Warehouse Space with Heavy-Duty Steel Racking Systems

2025-11-02 13:45:04

Heavy-duty steel racking systems have emerged as the cornerstone solution for businesses seeking to optimize their storage capacity while maintaining safety and accessibility. This comprehensive guide explores how industrial steel racking can transform warehouse operations, maximize storage density, and deliver substantial returns on investment through intelligent space management.

Understanding Heavy-Duty Steel Racking Systems

Heavy-duty steel racking systems represent engineered storage solutions designed to support substantial weight loads while providing optimal organization and accessibility. These systems typically feature high-grade steel construction with load capacities ranging from 2,000 to over 30,000 pounds per upright, making them ideal for industrial applications where durability and reliability are paramount. The modular nature of modern racking systems allows for customization to meet specific warehouse requirements, from selective pallet racking to drive-in systems and cantilever configurations.

The engineering behind heavy-duty steel racking incorporates advanced design principles that distribute weight evenly across structural components, preventing stress concentration and ensuring long-term stability. High-quality steel racking systems undergo rigorous testing to meet industry standards, including R-Mark certification and compliance with OSHA regulations, providing warehouse managers with confidence in their storage infrastructure investments.

Space Optimization Strategies with Steel Racking

Effective warehouse space utilization begins with strategic racking system design. Vertical space represents one of the most underutilized assets in many facilities, with traditional storage methods often leaving significant unused overhead capacity. Heavy-duty steel racking systems can extend up to 40 feet or more, effectively multiplying available storage area without expanding the facility footprint.

Selective pallet racking configurations offer the most versatile solution for warehouses handling diverse product types. This system design allows direct access to every pallet, making it ideal for operations with high SKU variety and frequent inventory rotation. The implementation of double-deep racking can increase storage density by up to 40% compared to selective systems, though it requires specialized handling equipment and reduces immediate accessibility.

Load Capacity and Safety Considerations

When implementing heavy-duty steel racking systems, understanding load capacity specifications is crucial for maintaining safety and operational efficiency. Each racking system features precise weight limits for individual beams, upright frames, and overall bay configurations. Proper load distribution prevents overloading, which can lead to structural failure and serious safety hazards.

Modern steel racking systems incorporate safety features designed to protect both inventory and personnel. Column protectors, row spacers, and end-of-aisle guards provide impact protection against forklift collisions and accidental damage. Load beams often include safety clips or locking mechanisms that prevent accidental dislodgement during pallet placement or removal. Regular safety inspections and maintenance protocols ensure continued compliance with safety standards and prevent potential accidents.

Customization Options for Specific Applications

Heavy-duty steel racking systems offer extensive customization options to address unique warehouse requirements. Specialized coatings and finishes protect against environmental factors such as humidity, temperature variations, and chemical exposure. Food-grade finishes meet NSF standards for facilities handling consumable products, while corrosion-resistant coatings suit cold storage applications and refrigerated environments.

Cantilever racking systems provide ideal solutions for storing long, bulky items such as lumber, piping, or carpet rolls. These systems feature arms extending from central columns without vertical obstructions, allowing easy loading and unloading of oversized materials. Push-back racking systems offer high-density storage solutions with last-in, first-out (LIFO) inventory rotation, ideal for operations with multiple pallets of the same SKU.

Installation and Implementation Best Practices

Proper installation of heavy-duty steel racking systems requires careful planning and execution to ensure optimal performance and safety. Site preparation begins with floor condition assessment, as concrete floor quality directly impacts racking stability and load capacity. Professional installation teams utilize laser alignment tools and precision measuring equipment to ensure upright plumbness and beam levelness within specified tolerances.

Proper installation of heavy-duty steel racking systems requires careful planning and execution to ensure optimal performance and safety. Site preparation begins with floor condition assessment, as concrete floor quality directly impacts racking stability and load capacity. Professional installation teams utilize laser alignment tools and precision measuring equipment to ensure upright plumbness and beam levelness within specified tolerances.

The implementation process should include comprehensive employee training programs covering proper loading techniques, weight distribution principles, and safety protocols. Clear labeling systems and inventory management procedures help maintain organized storage patterns and prevent overloading situations. Regular maintenance schedules, including bolt tightening, damage inspection, and load capacity verification, ensure continued system performance and safety compliance.

ROI Analysis and Cost Benefits

Investing in heavy-duty steel racking systems delivers substantial returns through multiple cost-saving mechanisms. Increased storage density reduces the need for facility expansion or additional warehouse space, potentially saving millions in real estate costs. Improved organization and accessibility reduce labor costs associated with inventory handling and order fulfillment processes.

The durability and longevity of steel racking systems provide excellent long-term value, with many installations lasting 20+ years with proper maintenance. Reduced product damage from improved storage conditions and handling procedures further contributes to cost savings. When evaluating ROI, businesses should consider both direct financial benefits and indirect advantages such as improved operational efficiency and enhanced safety records.

Future Trends in Steel Racking Technology

The evolution of steel racking technology continues to advance, incorporating smart features and automation capabilities. IoT-enabled racking systems can monitor load conditions, detect potential overloads, and provide real-time inventory data through integrated sensors. Automated storage and retrieval systems (AS/RS) combine steel racking structures with robotic handling equipment to maximize space utilization while minimizing labor requirements.

Sustainability considerations are increasingly influencing racking system design, with manufacturers incorporating recycled materials and energy-efficient production processes. Modular racking systems that can be easily reconfigured or expanded provide flexibility for growing operations while minimizing waste. These technological advances ensure that steel racking systems will continue to play a vital role in warehouse optimization for years to come.

Heavy-duty steel racking systems represent essential investments for warehouses seeking to maximize space utilization while maintaining safety and operational efficiency. By understanding the various system options, customization capabilities, and implementation best practices, businesses can create storage solutions that drive productivity and deliver substantial returns on investment. As warehouse operations continue to evolve, steel racking systems will remain fundamental to effective space management and operational success.

Tags: Maximize Warehouse Space, Heavy-Duty Steel Racking Systems, Steel Racking