-

Sarah

Hi there! Welcome to my shop. Let me know if you have any questions.

Sarah

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

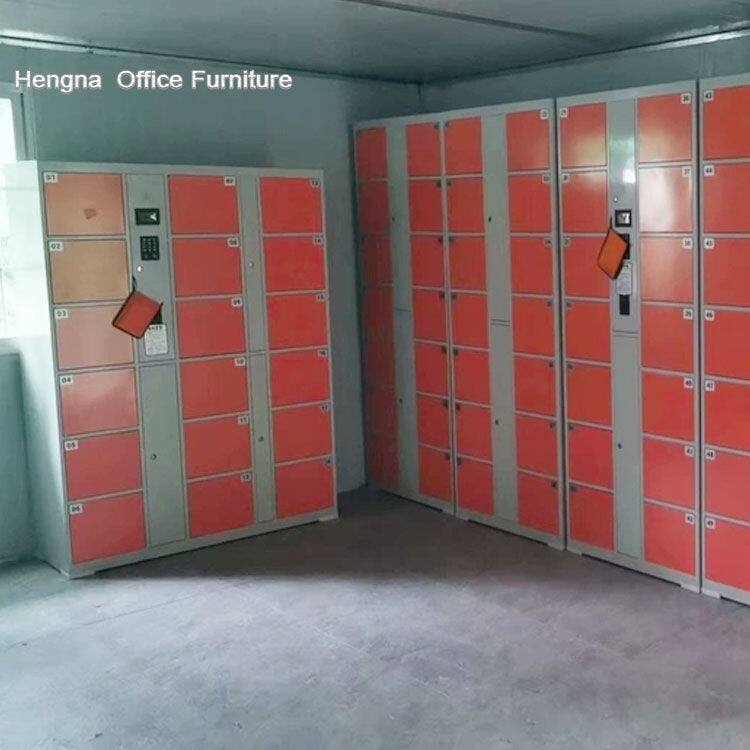

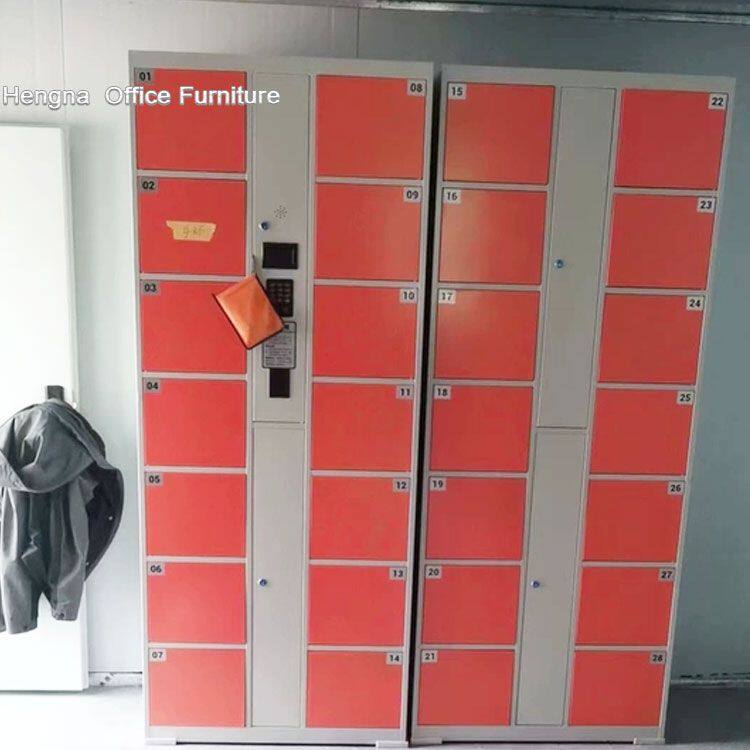

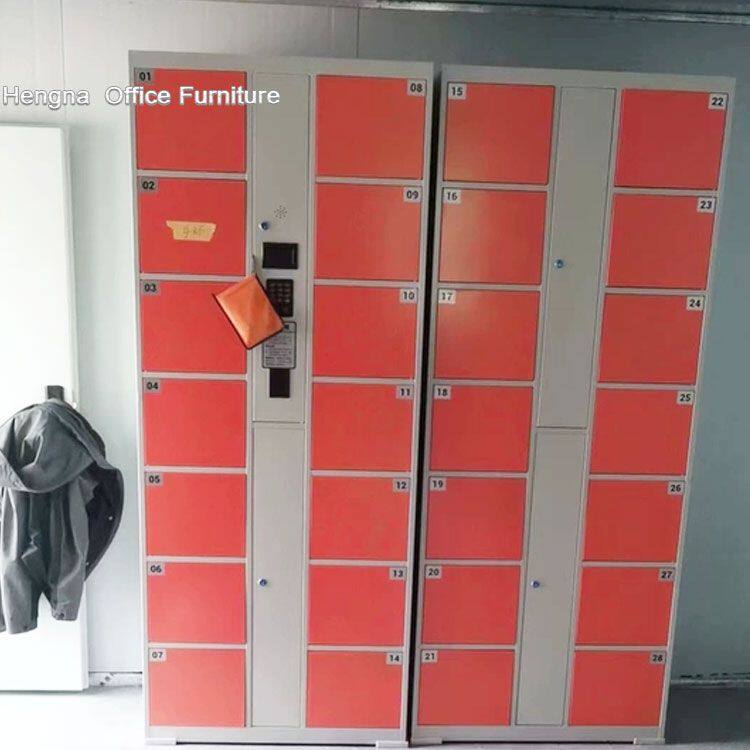

Streamline Warehouse Operations with E-Locker Asset Management Systems

2025-10-30 08:37:14

Modern warehouses and distribution centers face increasing pressure to optimize operations, improve efficiency, and maintain tight security controls over valuable assets. The complex logistics of managing tools, equipment, and sensitive materials in fast-paced warehouse environments requires sophisticated solutions that balance accessibility with security. Electronic locker asset management systems have emerged as powerful tools for streamlining warehouse operations, providing secure storage solutions that enhance productivity, reduce losses, and improve overall operational control. This comprehensive analysis explores how e-locker systems are transforming warehouse management and addressing the unique challenges of industrial environments.

The Asset Management Challenge in Warehouse Operations

Warehouses house thousands of valuable items, ranging from small tools and testing equipment to expensive machinery parts and sensitive materials. Managing these assets effectively is critical for maintaining operational efficiency and controlling costs. Traditional asset management methods often rely on manual tracking processes, sign-out sheets, or basic storage solutions that lack adequate security controls.

These conventional approaches create numerous challenges. Tools and equipment can be easily misplaced or stolen, resulting in costly replacements and operational delays. The lack of accurate tracking makes it difficult to maintain optimal inventory levels of critical supplies. Manual processes are time-consuming and prone to errors, creating inefficiencies that impact overall warehouse performance. Electronic locker systems address these challenges through automated, secure storage solutions that integrate with warehouse management systems.

How Electronic Locker Systems Transform Asset Management

Electronic locker systems revolutionize warehouse asset management through sophisticated automation and integration capabilities. When an employee needs to check out a tool or piece of equipment, they simply authenticate their identity usingtheir credentials through PIN codes, RFID badges, or biometric scanners. The system automatically logs the checkout time, user identification, and specific item retrieved. This automated process eliminates paperwork, reduces errors, and creates real-time visibility into asset utilization.

Enhanced Security and Loss Prevention Security is paramount in warehouse operations, where tools and equipment represent significant investments. Electronic locker systems provide robust protection through individual locking compartments that prevent unauthorized access. The detailed audit trails maintained by these systems create accountability, recording every checkout and return with precise timestamps and user identification. For high-value items or controlled equipment, electronic lockers can be programmed with additional security layers, such as dual authorization requirements or time-based access restrictions. The ability to monitor usage patterns helps identify unusual activity that might indicate theft or misuse. This comprehensive security approach significantly reduces losses and protects valuable warehouse assets. Integration with Warehouse Management Systems Modern electronic locker solutions seamlessly integrate with existing warehouse management systems (WMS), creating a unified asset management ecosystem. This integration enables real-time inventory updates, automated reorder triggers, and comprehensive reporting capabilities. When tools are checked out or returned, the WMS automatically updates inventory levels, ensuring accurate tracking of all warehouse assets. The connectivity also enables features such as predictive maintenance scheduling, where the system tracks tool usage and automatically schedules maintenance based on actual utilization rather than arbitrary time intervals. This data-driven approach optimizes equipment performance and extends asset lifespan while reducing unnecessary maintenance costs. Improving Operational Efficiency Electronic locker systems dramatically improve warehouse operational efficiency by eliminating time-consuming manual processes. Employees can quickly access needed tools without searching for equipment or waiting for supervisor approval. The self-service nature of these systems empowers workers while maintaining proper control and accountability. The reduction in equipment search time translates directly into increased productivity. Studies show that warehouse workers can spend up to 20% of their time searching for tools and equipment. Electronic locker systems can reduce this time by over 80%, resulting in significant productivity gains and improved operational throughput. Data Analytics and Performance Optimization The sophisticated monitoring capabilities of electronic locker systems provide valuable insights into warehouse operations. Usage analytics can reveal peak demand times, popular equipment types, and employee utilization patterns. This information helps warehouse managers optimize equipment allocation, schedule maintenance, and identify training opportunities. The data collected can also support continuous improvement initiatives by identifying bottlenecks, inefficiencies, and opportunities for process optimization. Understanding how assets are used enables data-driven decision-making that enhances overall warehouse performance and reduces operational costs. Employee Accountability and Training Electronic locker systems promote employee accountability by creating clear records of equipment usage and responsibility. When workers know that their tool usage is being tracked, they are more likely to properly care for equipment and follow established procedures. This accountability culture extends to other areas of warehouse operations, contributing to overall operational excellence. The system can also identify training needs by tracking which employees frequently use specific equipment or who may require additional instruction on proper tool handling. This insight enables targeted training programs that improve employee skills and reduce equipment damage from improper use. Scalability and Future-Proofing As warehouse operations grow and evolve, electronic locker systems provide the scalability needed to accommodate changing requirements. Modular designs allow facilities to add additional locker units as inventory expands or new equipment types are introduced. The flexible configuration options ensure compatibility with diverse asset sizes and storage requirements. The technology behind electronic locker systems continues to advance, with regular software updates and feature enhancements that keep systems current with industry best practices. This future-proofing approach protects investments and ensures long-term viability as warehouse operations become increasingly sophisticated and automated. Cost-Effectiveness and Return on Investment While the initial investment in electronic locker systems may seem substantial, the long-term financial benefits are significant. Reduced equipment losses, lower administrative costs, and improved productivity all contribute to strong returns on investment. The ability to optimize equipment utilization also reduces the need for redundant purchases, further enhancing cost-effectiveness. Many facilities report payback periods of 12-18 months for electronic locker implementations, with ongoing annual savings that continue throughout the system’s lifespan. The reduction in equipment downtime and improved operational efficiency also generates indirect financial benefits that extend beyond direct cost savings. Supporting Safety and Compliance Warehouse safety is enhanced through electronic locker systems that ensure proper equipment storage and maintenance tracking. The ability to verify that employees have appropriate training and authorization before accessing certain equipment helps prevent accidents and injuries. The system can also enforce safety protocols by requiring regular equipment inspections or maintenance checks. For regulated industries, electronic locker systems support compliance requirements through detailed record-keeping and audit capabilities. The ability to demonstrate proper equipment control and maintenance practices can be valuable during regulatory inspections and certification processes.

Employee Accountability and Training Electronic locker systems promote employee accountability by creating clear records of equipment usage and responsibility. When workers know that their tool usage is being tracked, they are more likely to properly care for equipment and follow established procedures. This accountability culture extends to other areas of warehouse operations, contributing to overall operational excellence. The system can also identify training needs by tracking which employees frequently use specific equipment or who may require additional instruction on proper tool handling. This insight enables targeted training programs that improve employee skills and reduce equipment damage from improper use. Scalability and Future-Proofing As warehouse operations grow and evolve, electronic locker systems provide the scalability needed to accommodate changing requirements. Modular designs allow facilities to add additional locker units as inventory expands or new equipment types are introduced. The flexible configuration options ensure compatibility with diverse asset sizes and storage requirements. The technology behind electronic locker systems continues to advance, with regular software updates and feature enhancements that keep systems current with industry best practices. This future-proofing approach protects investments and ensures long-term viability as warehouse operations become increasingly sophisticated and automated. Cost-Effectiveness and Return on Investment While the initial investment in electronic locker systems may seem substantial, the long-term financial benefits are significant. Reduced equipment losses, lower administrative costs, and improved productivity all contribute to strong returns on investment. The ability to optimize equipment utilization also reduces the need for redundant purchases, further enhancing cost-effectiveness. Many facilities report payback periods of 12-18 months for electronic locker implementations, with ongoing annual savings that continue throughout the system’s lifespan. The reduction in equipment downtime and improved operational efficiency also generates indirect financial benefits that extend beyond direct cost savings. Supporting Safety and Compliance Warehouse safety is enhanced through electronic locker systems that ensure proper equipment storage and maintenance tracking. The ability to verify that employees have appropriate training and authorization before accessing certain equipment helps prevent accidents and injuries. The system can also enforce safety protocols by requiring regular equipment inspections or maintenance checks. For regulated industries, electronic locker systems support compliance requirements through detailed record-keeping and audit capabilities. The ability to demonstrate proper equipment control and maintenance practices can be valuable during regulatory inspections and certification processes.

Tags: E-Locker, Streamline Warehouse Operations, E-Locker Asset Management Systems