-

Sarah

Hi there! Welcome to my shop. Let me know if you have any questions.

Sarah

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

Fire and Explosion Protection Standards in Petrochemical Plants

2025-10-28 15:38:53

Petrochemical plants represent some of the most hazardous industrial environments, requiring stringent fire and explosion protection measures. Understanding and implementing comprehensive safety standards is essential for protecting personnel, facilities, and surrounding communities.

Petrochemical Industry Hazards

Petrochemical facilities face multiple risk factors:

Flammable Gas Clouds: Vapor releases from process equipment

Vapor Cloud Explosions: Large-scale vapor ignitions

Pool Fires: Liquid spill fires

Jet Fires: High-pressure stream releases

Flash Fires: Rapid flame propagation

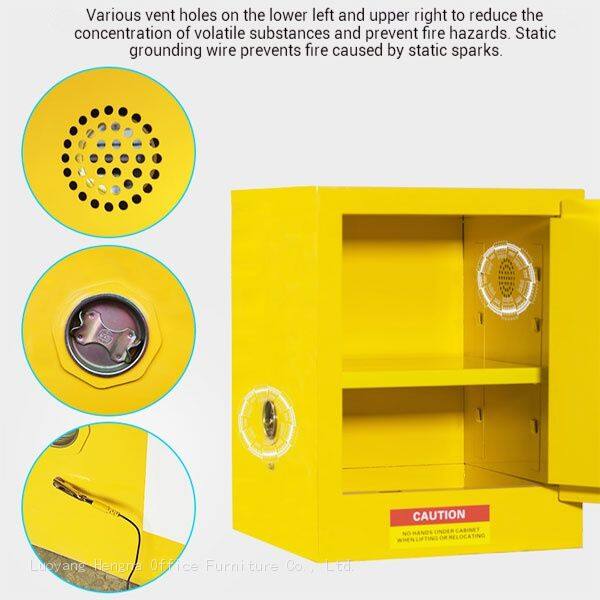

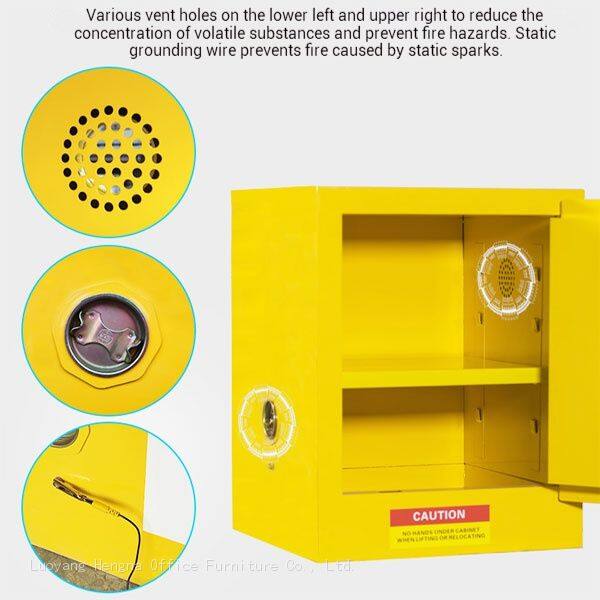

The double-wall construction with 40mm insulation gap in safety cabinets provides critical protection against these hazards, containing potential incidents and preventing escalation.

Regulatory Framework Overview

Safety Cabinet Specifications

Technical Requirements:

Construction: 1.2mm cold-rolled steel with double walls

Fire Rating: Minimum 90-minute protection

Explosion Venting: Pressure relief mechanisms

Temperature Monitoring: Integrated sensor systems

Gas Detection: Compatible with facility monitoring systems

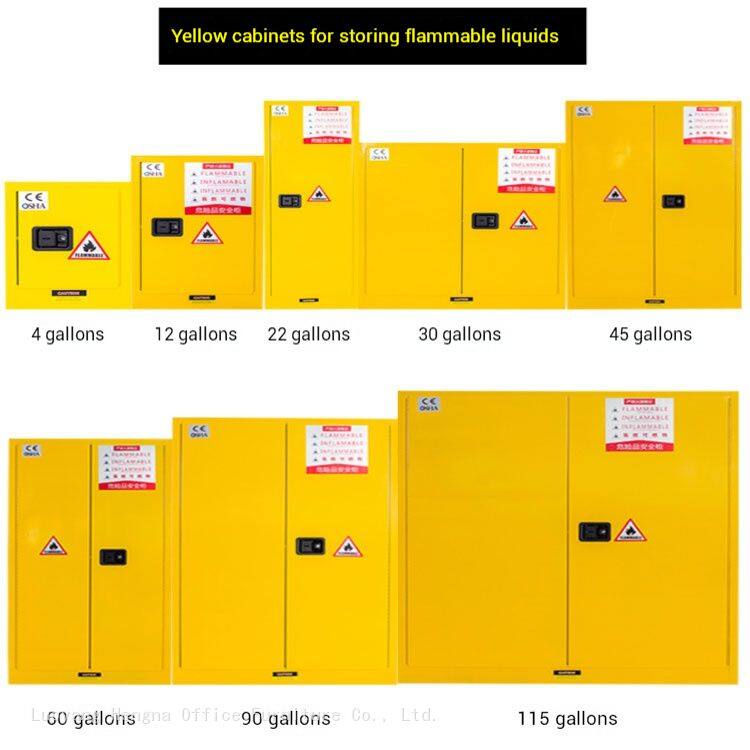

Storage Capacity Planning

| Facility Size | Cabinet Capacity | Storage Requirements |

|---|---|---|

| Small Plant | 45-60 Gallon | Limited chemical inventory |

| Medium Plant | 90-110 Gallon | Moderate storage needs |

| Large Complex | Multiple 110 Gallon | Extensive chemical storage |

Facility Design Integration

Safety System Integration:

Hazardous Area Classification: Proper equipment selection

Safe Distance Requirements: Separation from ignition sources

Fire Protection Systems: Comprehensive coverage

Emergency Response: Clear evacuation routes

Environmental Protection: Spill containment measures

Operational Safety Procedures

Daily Safety Protocols:

Permit-to-Work Systems: Controlled hazardous activities

Lockout/Tagout Procedures: Equipment maintenance safety

Hot Work Permits: Welding and cutting controls

Confined Space Entry: Tank access procedures

Management of Change: Process modification controls

Emergency Response Planning

Comprehensive Emergency Measures:

Fire Brigade Training: Specialized response teams

Emergency Drills: Regular scenario practice

Community Notification: Public alert systems

Medical Response: Injury treatment capabilities

Environmental Protection: Spill containment procedures

Quality Assurance Systems

Continuous Improvement:

Regular Audits: Compliance verification

Performance Metrics: Safety incident tracking

Training Programs: Employee competency development

Documentation: Comprehensive record keeping

Management Review: Leadership oversight

Cost-Benefit Analysis

Investment Returns:

Risk Reduction: 95% decrease in major incidents

Operational Continuity: Minimized production interruptions

Insurance Benefits: Significant premium reductions

Regulatory Compliance: Avoidance of penalties

Reputation Protection: Enhanced stakeholder confidence

By implementing these comprehensive safety standards, petrochemical plants can significantly reduce risks while maintaining operational efficiency and regulatory compliance.

Tags: Fire and Explosion Protection Standards