-

Sarah

Hi there! Welcome to my shop. Let me know if you have any questions.

Sarah

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

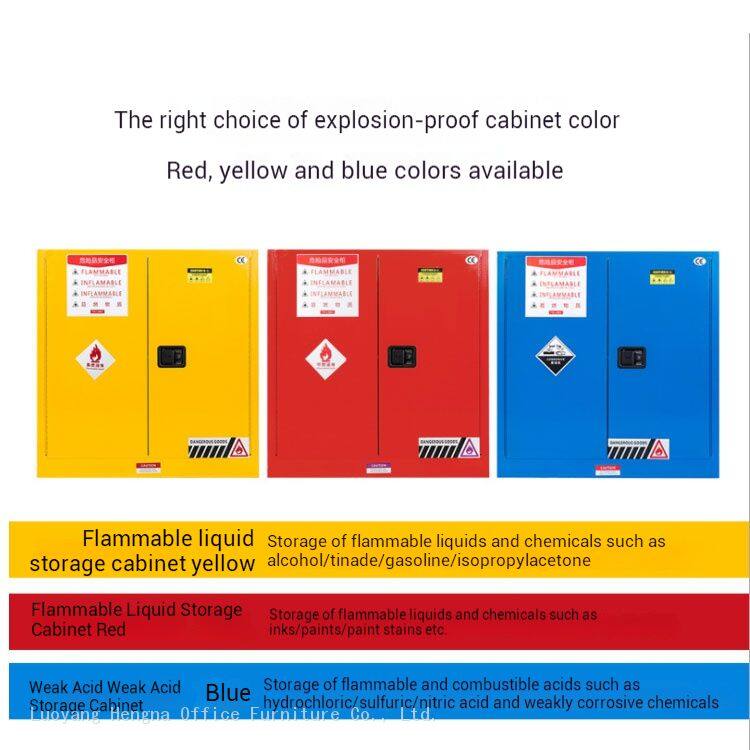

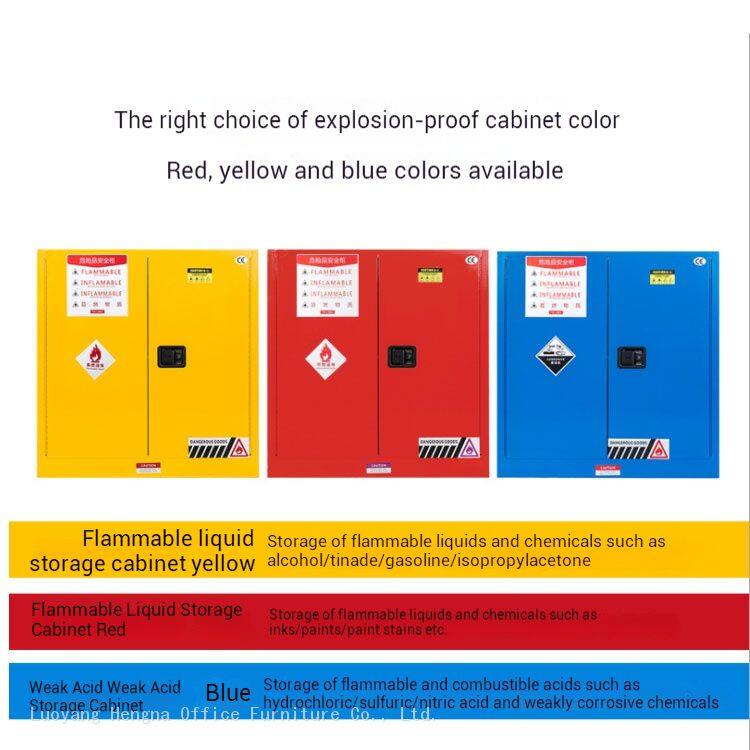

How Chemical Plants Should Store Flammable Liquids Safely

2025-10-28 15:33:59

Chemical plants face unique challenges when storing flammable liquids, requiring robust safety solutions that meet stringent regulatory standards. Modern flammable safety cabinets provide comprehensive protection through advanced engineering and thoughtful design.

Understanding Flammable Liquid Storage Requirements

Chemical plants must store various flammable substances including solvents, alcohols, and petroleum-based products. According to OSHA standards, these materials require specialized storage solutions with specific safety features. The 1.2mm cold-rolled steel construction with double-layer fireproof design (40mm spacing) provides optimal thermal protection and structural integrity.

Essential Safety Cabinet Features

Key Technical Specifications:

Material: 1.2mm galvanized cold-rolled steel

Structure: Double-wall construction with 40mm air gap

Locking System: Three-point linkage with dual-lock mechanism

Leak Protection: Built-in spill containment trough

Ventilation: Flame arrestor vents for pressure regulation

Storage Capacity Options

| Capacity | External Dimensions (H×W×D) | Internal Dimensions (H×W×D) | Application |

|---|---|---|---|

| 4 Gallon | 560×430×460mm | 460×340×370mm | Small-scale storage |

| 12 Gallon | 890×590×460mm | 790×500×370mm | Medium quantities |

| 22 Gallon | 1650×590×460mm | 1550×500×370mm | Large volume storage |

| 45 Gallon | 1650×1090×460mm | 1550×1000×370mm | Industrial capacity |

Implementation Best Practices

Critical Safety Measures:

Location: Place away from heat sources and ignition points

Ventilation: Ensure proper airflow around cabinets

Access: Maintain clear pathways for emergency response

Labeling: Use clear hazard identification markings

Inspection: Regular maintenance and integrity checks

Compliance and Certification

Quality safety cabinets must meet multiple standards:

OSHA 29 CFR 1910.106: Flammable liquid storage requirements

NFPA 30: Flammable and combustible liquids code

CE Certification: European safety standards compliance

Cost-Benefit Analysis

Investing in quality safety cabinets provides:

Risk Reduction: 90% decrease in fire-related incidents

Insurance Benefits: Lower premiums through improved safety

Regulatory Compliance: Avoidance of fines and penalties

Operational Efficiency: Organized storage and easy access

Maintenance Guidelines

Regular Inspection Checklist:

Monthly visual inspection for damage

Quarterly lock mechanism testing

Semi-annual ventilation system check

Annual professional certification

Immediate repair of any identified issues

By implementing these comprehensive safety measures, chemical plants can significantly reduce fire risks while maintaining operational efficiency and regulatory compliance.

Tags: Chemical Plants, Chemical Plants Should Store Flammable Liquids