Home > Blog > Choosing Heavy Duty Shelving? Essential Traits for Tool-Free Assembly & Warehouse Efficiency

-

Sarah

Hi there! Welcome to my shop. Let me know if you have any questions.

Sarah

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

Choosing Heavy Duty Shelving? Essential Traits for Tool-Free Assembly & Warehouse Efficiency

2025-10-22 19:13:57

In the complex ecosystem of warehouse management, shelving selection is far more than a simple purchasing decision—it’s a strategic choice that impacts operational efficiency, labor costs, and overall productivity. As warehouse managers and operations professionals face increasing pressure to optimize performance while controlling costs, the importance of selecting the right heavy duty shelving has never been greater. This comprehensive guide explores the essential traits to look for when choosing heavy duty shelving, with special focus on tool-free assembly systems and their impact on warehouse efficiency.

Understanding the True Cost of Shelving Decisions

Before diving into specific features, it’s crucial to understand how shelving decisions impact your bottom line. The wrong choice can result in hidden costs that far exceed the initial purchase price.

Beyond the Price Tag: Total Cost of Ownership

When evaluating shelving options, consider these cost factors:

Installation Costs: Labor, equipment, and time required for setup

Maintenance Requirements: Ongoing upkeep and potential repairs

Operational Efficiency: Impact on picking, stocking, and general workflow

Lifespan Considerations: How long before replacement becomes necessary

Adaptability Costs: Expenses associated with reconfiguration or expansion

The Efficiency Dividend of Quality Shelving:

Investing in the right shelving system delivers measurable returns:

Labor Productivity: Well-designed systems can improve picking efficiency by 25-40%

Space Utilization: Optimal configurations can increase storage capacity by 30-50%

Safety Improvements: Quality systems reduce workplace accidents and associated costs

Scalability: Adaptable systems eliminate the need for complete replacement as needs change

Essential Trait 1: Revolutionary Tool-Free Assembly Systems

The assembly method of your shelving system has profound implications for installation time, labor costs, and long-term flexibility. Modern tool-free assembly systems represent a significant advancement in shelving technology.

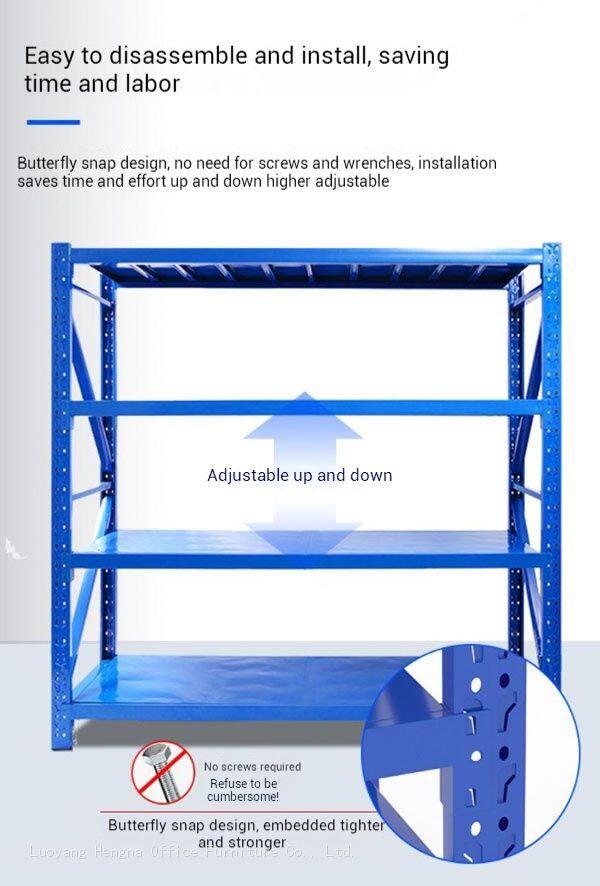

The Butterfly Hole Advantage:

Innovative butterfly hole mechanisms have transformed shelving assembly:

Precision Engineering: Specially designed holes and connectors ensure perfect alignment and strength

No Screws or Bolts: Eliminates the need for fasteners, tools, and specialized labor

Secure Connections: Creates strong, stable connections that resist loosening over time

Quick Disassembly: Allows for easy reconfiguration or relocation as warehouse needs evolve

Real-World Impact of Tool-Free Assembly:

The benefits extend far beyond initial installation:

Installation Time Reduction: Complete setup in minutes rather than hours

Labor Cost Savings: Lower skill requirements and fewer personnel needed

Reduced Disruption: Minimal downtime during installation or reconfiguration

Enhanced Safety: Eliminates risks associated with power tools and complex assembly

Assembly Efficiency Comparison:

| Assembly Method | Installation Time | Labor Cost | Reconfiguration Difficulty |

|---|---|---|---|

| Traditional Bolted | 45-60 minutes per unit | High | Difficult |

| Basic Snap-Together | 15-20 minutes per unit | Moderate | Moderate |

| Butterfly Hole System | 5-10 minutes per unit | Low | Easy |

Essential Trait 2: Industrial Strength Construction

While assembly efficiency is important, the fundamental strength and durability of your shelving system is paramount. Industrial strength construction ensures safety, longevity, and reliable performance under demanding conditions.

Key Indicators of Industrial Strength:

When evaluating construction quality, look for these essential characteristics:

Material Thickness: Premium systems feature 0.5MM laminate thickness and 1.0MM column and beam thickness

Steel Quality: High-grade steel with consistent properties throughout

Connection Design: Reinforced connection points that resist stress and fatigue

Finish Quality: Industrial-grade coatings that resist corrosion and wear

The Importance of Attention to Detail:

Quality manufacturers focus on the details that make a difference:

Precision Manufacturing: Components manufactured to tight tolerances for perfect fit

Quality Control: Comprehensive inspection processes throughout production

Testing Protocols: Rigorous testing to verify performance claims

Documentation: Clear specifications and installation instructions

Construction Quality vs. Performance:

| Construction Quality | Load Capacity | Lifespan | Maintenance Requirements |

|---|---|---|---|

| Premium Industrial | Exceeds specifications | 10-15 years | Minimal |

| Standard Commercial | Meets specifications | 5-8 years | Moderate |

| Economy Light-Duty | Below specifications | 2-4 years | High |

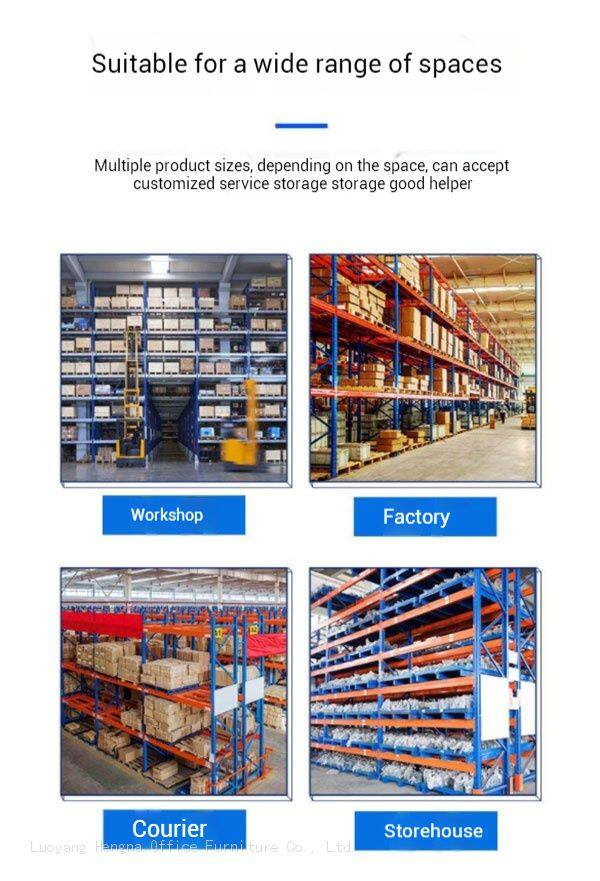

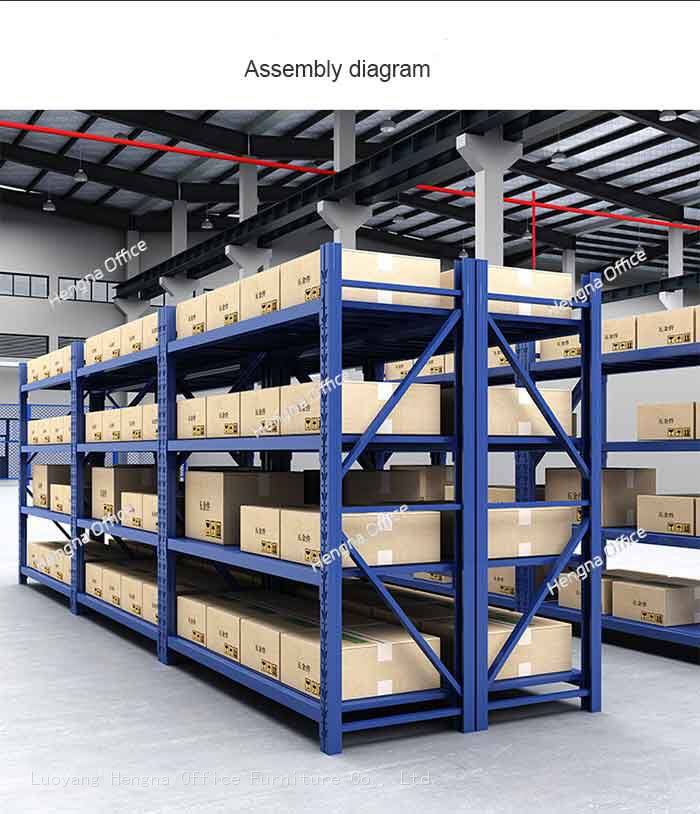

Essential Trait 3: Optimized for Warehouse Efficiency

The best heavy duty shelving systems are designed specifically to enhance warehouse efficiency, not just provide storage space. This trait encompasses numerous design elements that contribute to overall operational performance.

Efficiency-Enhancing Design Features:

Look for these design elements that improve warehouse operations:

Accessibility Design: Shelves positioned for easy reach and visibility

Adjustability: Easy height adjustment to accommodate different inventory sizes

Modularity: Components that can be reconfigured as needs change

Accessory Compatibility: Support for bins, dividers, and other organizational tools

Space Optimization Capabilities:

Efficient shelving maximizes every square foot of warehouse space:

Vertical Utilization: Takes full advantage of available height

Aisle Optimization: Balances accessibility with space efficiency

Density Configuration: Supports high-density storage where appropriate

Flow-Through Design: Facilitates efficient material movement

Efficiency Impact Metrics:

Quality shelving systems deliver measurable improvements:

Picking Efficiency: 25-40% improvement in items picked per hour

Space Utilization: 30-50% increase in storage capacity within same footprint

Inventory Accuracy: 15-25% improvement in inventory management

Labor Productivity: 20-30% reduction in labor costs per unit handled

Essential Trait 4: Safety and Compliance Features

Safety should never be compromised in warehouse operations. Quality heavy duty shelving incorporates numerous safety features that protect both workers and inventory.

Critical Safety Features:

Look for these essential safety elements:

Load Capacity Verification: Clear labeling and testing certification

Stability Design: Features that prevent tipping and collapse

Edge Protection: Smooth edges and corners to prevent injury

Weight Distribution Engineering: Design that prevents dangerous load concentrations

Compliance Considerations:

Ensure your shelving meets or exceeds relevant standards:

OSHA Compliance: Meets or exceeds Occupational Safety and Health Administration requirements

Industry Standards: Compliance with relevant shelving and storage industry standards

Local Regulations: Meets all local building and safety codes

Insurance Requirements: Satisfies insurance company specifications for commercial storage

Safety Investment Return:

Investing in safety features delivers substantial returns:

Reduced Accident Rates: Quality systems can reduce workplace accidents by 40-60%

Lower Insurance Costs: Safety improvements often lead to reduced insurance premiums

Less Downtime: Fewer accidents mean less operational disruption

Improved Morale: Safer working environments improve employee satisfaction and retention

Essential Trait 5: Scalability and Future-Proofing

Warehouse needs evolve over time, and your shelving system should be able to evolve with them. Scalability is a crucial trait that protects your investment and ensures long-term value.

Scalability Features to Look For:

These features enable your shelving system to grow with your business:

Expandable Design: Ability to add units and create larger systems

Compatibility: New components work with existing installations

Reconfigurability: Easy to modify layouts as needs change

Capacity Upgrades: Options to increase capacity without complete replacement

Future-Planning Considerations:

When selecting shelving, consider these future needs:

Business Growth Projections: Anticipate increases in inventory volume and variety

Technology Integration: Consider future automation and technology requirements

Workflow Changes: Plan for potential changes in material flow and processes

Industry Trends: Stay ahead of evolving warehouse management practices

Scalability Impact on Total Cost of Ownership:

| Scalability Level | Initial Investment | Expansion Cost | Adaptability | Long-Term Value |

|---|---|---|---|---|

| High Scalability | Moderate | Low | Excellent | Highest |

| Moderate Scalability | Standard | Moderate | Good | Medium |

| Low Scalability | Low | High | Poor | Lowest |

Making the Right Choice: A Decision Framework

With these essential traits in mind, use this framework to guide your shelving selection process:

Step 1: Assessment Phase

Document current inventory types, sizes, and weights

Measure available space and identify constraints

Map current workflow patterns and identify bottlenecks

Project future growth and changing needs

Step 2: Requirements Definition

Establish minimum capacity requirements for each shelf level

Determine essential assembly features (tool-free capability, etc.)

Identify specific safety and compliance requirements

Define scalability needs and expansion plans

Step 3: Evaluation Process

Compare options against the five essential traits

Calculate total cost of ownership for each alternative

Consider supplier reputation and support capabilities

Test samples when possible to verify quality claims

Step 4: Implementation Planning

Develop detailed installation and configuration plans

Train staff on proper use and maintenance procedures

Establish monitoring and maintenance schedules

Plan for future expansion and reconfiguration

Choosing heavy duty shelving with these essential traits—tool-free assembly, industrial strength construction, efficiency optimization, safety features, and scalability—represents a strategic investment in your warehouse’s future success. While the initial evaluation process may require time and effort, the long-term benefits in efficiency, safety, and adaptability deliver substantial returns.

Remember that quality shelving is not an expense—it’s an investment in operational excellence that pays dividends through improved productivity, reduced costs, and enhanced flexibility. By prioritizing these essential traits and following a structured selection process, you can choose a shelving system that not only meets your current needs but also adapts to future challenges and opportunities.

Invest in quality heavy duty shelving today and build a foundation for warehouse efficiency that will serve your operation well into the future.

Tags: Choosing Heavy Duty Shelving, Warehouse Efficiency Heavy Duty Shelving