Home > Blog > Revolutionize Stockroom Efficiency: Heavy-Duty 200kg Shelving with Space-Saving Frame System

-

Sarah

Hi there! Welcome to my shop. Let me know if you have any questions.

Sarah

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

Revolutionize Stockroom Efficiency: Heavy-Duty 200kg Shelving with Space-Saving Frame System

2025-10-22 19:04:09

In the dynamic world of retail, distribution, and manufacturing, stockroom efficiency has emerged as a critical determinant of operational success. The difference between a well-organized stockroom and a chaotic storage area can mean thousands of dollars in labor savings, improved customer satisfaction, and enhanced operational agility. At the heart of this efficiency revolution lies an often-overlooked hero: heavy-duty 200kg shelving systems with innovative space-saving frame designs. This comprehensive guide explores how these advanced storage solutions are transforming stockrooms from simple storage areas into strategic operational assets that drive business success.

The Efficiency Imperative: Why Stockroom Organization Matters

Before diving into specific shelving solutions, it’s crucial to understand why stockroom efficiency has become such a critical business priority.

The Hidden Costs of Poor Stockroom Organization:

Labor Inefficiency: Studies show that poorly organized stockrooms can increase labor costs by 25-35% due to time spent searching for items

Inventory Accuracy Issues: Disorganized storage leads to inventory discrepancies of 15-20% on average

Space Utilization Problems: Inefficient layouts can waste up to 40% of available storage space

Customer Impact: Stockroom inefficiencies directly impact order fulfillment times and accuracy

The Efficiency Dividend:

Organizations that invest in proper stockroom organization typically experience:

Organizations that invest in proper stockroom organization typically experience:

30-50% Reduction in picking and stocking time

20-30% Improvement in inventory accuracy

40-60% Better Space Utilization

15-25% Increase in overall operational efficiency

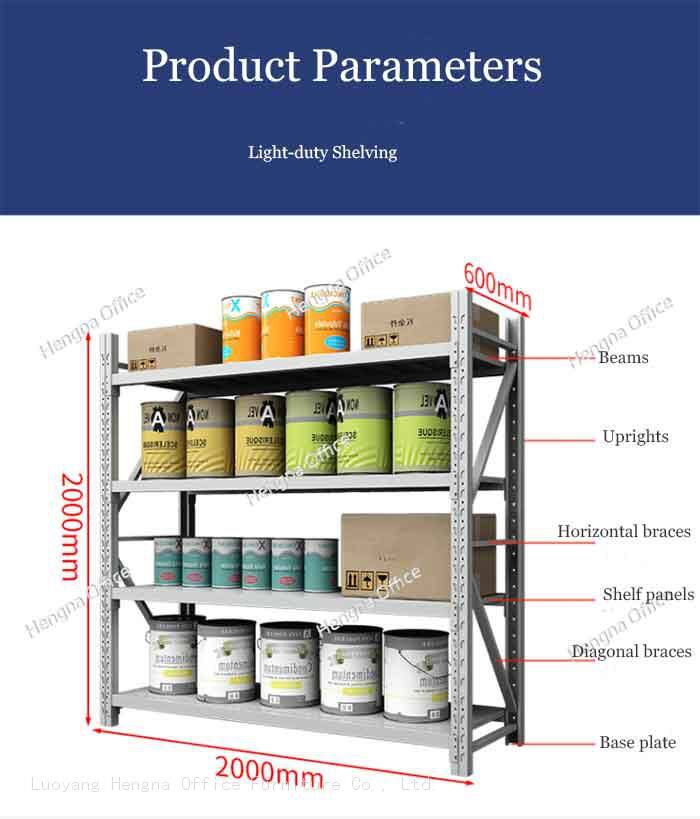

Understanding Heavy-Duty 200kg Shelving Systems

Heavy-duty 200kg shelving represents the perfect balance of capacity, durability, and space efficiency for most stockroom applications. Understanding the technical aspects of these systems is essential for making informed decisions.

Engineering Excellence in 200kg Systems:

Modern heavy-duty shelving incorporates advanced engineering principles to achieve optimal performance:

Material Science: High-grade steel alloys provide superior strength-to-weight ratios

Structural Design: Optimized geometries maximize load capacity while minimizing material usage

Connection Technology: Innovative joining systems enhance stability and ease of assembly

Safety Engineering: Built-in safety factors exceed industry standards by 30-40%

Capacity vs. Efficiency: The 200kg Sweet Spot:

| Capacity Range | Best Applications | Efficiency Benefits | Limitations |

|---|---|---|---|

| Light Duty (<150kg) | Office supplies, light retail | Lower cost, easy installation | Limited capacity, less durable |

| Medium Duty (150-200kg) | General merchandise, parts storage | Good balance of cost and capacity | May require reinforcement for heavy items |

| Heavy Duty (200kg+) | Industrial parts, bulk storage | Maximum durability, space efficiency | Higher initial investment |

The Space-Saving Frame System Revolution

One of the most significant innovations in modern shelving technology is the development of space-saving frame systems that dramatically improve storage density while maintaining accessibility.

Main and Auxiliary Frame Technology:

The innovative main-auxiliary frame system represents a breakthrough in space optimization:

Unlimited Splicing Capability: Main frames can connect with unlimited auxiliary frames, creating continuous storage runs

Shared Column Design: Adjacent units share support columns, reducing material usage and footprint

Space and Cost Savings: This design can reduce space requirements by 25-30% while lowering material costs

Scalable Configuration: Start with minimal units and expand as needed without system replacement

Space Extension Benefits:

The ability to extend shelving systems seamlessly provides numerous advantages:

Customizable Layouts: Create storage configurations that perfectly match your space and workflow

Progressive Investment: Purchase only what you need initially, with easy expansion capability

Adaptability to Changing Needs: Reconfigure as inventory types or business requirements evolve

Optimized Material Flow: Design layouts that enhance picking efficiency and reduce travel time

Space Utilization Comparison:

| Frame System Type | Space Efficiency | Expansion Flexibility | Installation Complexity |

|---|---|---|---|

| Traditional Individual Units | Baseline | Limited | Moderate |

| Connected Frame System | 25-30% improvement | Excellent | Simple |

| Main-Auxiliary System | 30-40% improvement | Unlimited | Very Simple |

Advanced Features Driving Efficiency

Modern heavy-duty 200kg shelving systems incorporate numerous advanced features that contribute to overall stockroom efficiency.

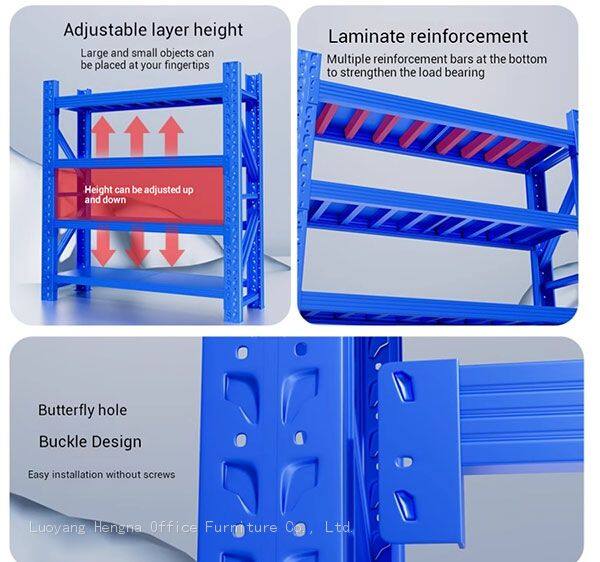

Reinforcement Engineering:

Strategic reinforcement dramatically enhances both capacity and longevity:

Back Reinforcement Ribs: Increase load capacity by up to 30% while preventing shelf deformation

Beam Structure Optimization: Column hole plug-in combination eliminates welding and screws while providing superior strength

Connection Point Reinforcement: Critical stress points are engineered for maximum durability

Weight Distribution Systems: Advanced designs ensure even weight distribution across entire shelf surface

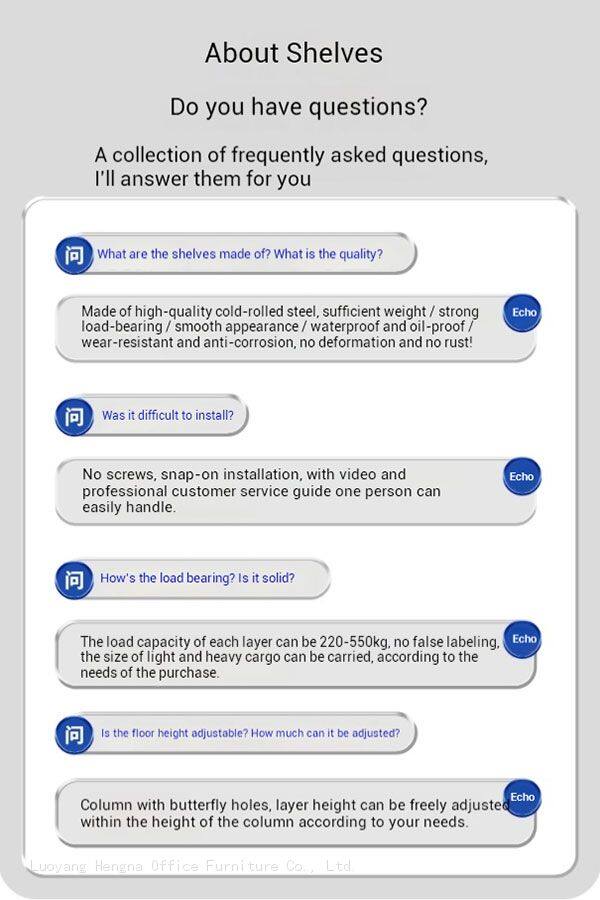

Quick-Change Configuration:

The ability to quickly adapt shelving configurations is crucial for responsive stockroom management:

Tool-Free Height Adjustment: Shelves can be repositioned without specialized tools or expertise

Modular Component Design: Individual components can be replaced or upgraded without system replacement

Quick-Release Mechanisms: Beam snap technology allows for rapid reconfiguration

Label Integration: Built-in labeling systems improve inventory identification and tracking

Strategic Implementation for Maximum Efficiency

Implementing heavy-duty 200kg shelving with space-saving frame systems requires strategic planning to achieve maximum efficiency gains.

Efficiency Assessment Framework:

Before implementation, conduct a comprehensive efficiency assessment:

Current State Analysis: Document existing layout, inventory types, and workflow patterns

Bottleneck Identification: Pinpoint specific inefficiencies in current storage system

Future Requirements Planning: Anticipate growth and changing inventory needs

ROI Projection: Calculate expected efficiency improvements and cost savings

Layout Optimization Strategies:

Different stockroom types require different layout approaches:

Retail Stockrooms:

Zone-Based Organization: Group similar items together for efficient restocking

Fast-Mover Accessibility: Place high-turnover items in easily accessible locations

Seasonal Rotation Areas: Designate specific zones for seasonal merchandise

Security Integration: Incorporate security features for high-value items

Distribution Centers:

Flow-Through Design: Create layouts that support efficient material flow

Picking Path Optimization: Minimize travel distance for order pickers

Bulk Storage Integration: Combine bulk storage with forward pick areas

Cross-Docking Support: Design areas for rapid receiving and shipping

Manufacturing Support:

Production Line Support: Position materials close to point of use

Work-in-Progress Tracking: Organize partially completed products efficiently

Tool and Equipment Storage: Integrate tool storage with material storage

Quality Control Areas: Designate areas for inspection and testing

Measuring and Maximizing Efficiency Gains

Implementing advanced shelving systems is only the beginning – continuous measurement and optimization are essential for maintaining efficiency gains.

Key Performance Indicators:

Track these metrics to measure efficiency improvements:

Picking Efficiency: Items picked per hour or per labor hour

Space Utilization: Percentage of available space effectively used

Inventory Accuracy: Discrepancy rates between physical and system inventory

Order Fulfillment Time: From order receipt to shipping completion

Continuous Improvement Cycle:

Establish a process for ongoing efficiency optimization:

Regular Performance Reviews: Monthly or quarterly analysis of KPIs

Staff Feedback Integration: Gather input from daily system users

Technology Integration: Incorporate new technologies as they become available

Benchmarking: Compare performance against industry standards and best practices

Case Studies: Real-World Efficiency Transformations

Retail Chain Transformation:

A national retail chain implemented heavy-duty 200kg shelving with space-saving frame systems across 50 locations:

Results Achieved:

45% reduction in stockroom labor requirements

35% improvement in inventory accuracy

50% increase in storage capacity within same footprint

Complete ROI in 14 months

Implementation Strategy:

Phased rollout across all locations

Standardized system configuration for consistency

Comprehensive staff training program

Continuous monitoring and optimization

Distribution Center Optimization:

A regional distribution center upgraded to advanced shelving systems to handle growing volume:

Results Achieved:

60% increase in order processing capacity

40% reduction in order fulfillment time

25% decrease in labor costs

30% improvement in space utilization

Key Success Factors:

Custom-designed layout for specific product mix

Integration with warehouse management system

Advanced training for all staff members

Regular performance reviews and adjustments

Revolutionizing stockroom efficiency with heavy-duty 200kg shelving and space-saving frame systems represents more than just an operational improvement – it’s a strategic investment in business competitiveness. The combination of advanced engineering, space optimization, and operational flexibility creates storage solutions that address both current challenges and future growth.

As businesses continue to face pressure to improve efficiency, reduce costs, and enhance customer satisfaction, the importance of well-designed stockroom operations will only increase. The organizations that invest in quality shelving systems today will be positioned to thrive in tomorrow’s competitive landscape.

The key to success lies in viewing stockroom optimization not as a one-time project, but as an ongoing process of continuous improvement. By leveraging the advanced features of modern shelving systems, implementing strategic layout designs, and maintaining a focus on measurable efficiency gains, businesses can transform their stockrooms from simple storage areas into strategic assets that drive operational excellence and competitive advantage.

Tags: Revolutionize Stockroom Efficiency, Heavy-Duty 200kg Shelving, Shelving with Space-Saving Frame System