Home > Blog > Maximize Warehouse Space: Choosing Industrial Shelving (200-400kg) with Flexible Layer Configuration

-

Sarah

Hi there! Welcome to my shop. Let me know if you have any questions.

Sarah

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

Maximize Warehouse Space: Choosing Industrial Shelving (200-400kg) with Flexible Layer Configuration

2025-10-22 18:41:04

In today’s competitive business landscape, warehouse space represents one of the most significant operational costs for many businesses. With real estate prices continuing to rise and e-commerce driving increased inventory demands, maximizing every square foot of warehouse space has become more critical than ever. Industrial shelving systems with 200-400kg capacity and flexible layer configuration offer the perfect solution for businesses looking to optimize their storage density without compromising accessibility or safety. This comprehensive guide will explore how to select and implement the ideal shelving system to transform your warehouse space utilization.

The Strategic Importance of Proper Weight Capacity (200-400kg)

Understanding why the 200-400kg capacity range is ideal for most warehouse applications will help you make an informed decision that balances capability with cost-effectiveness.

The 200-400kg Advantage:

Optimal Load Range: Perfectly suited for most inventory items, from automotive parts to medium-sized equipment

Structural Efficiency: Provides excellent strength-to-weight ratio, minimizing material costs

Accessibility: Maintains easy access to stored items without specialized equipment

Safety Factor: Reduces risk of overloading compared to lighter-duty systems

Assessing Your Warehouse’s Capacity Needs:

To determine the right capacity within this range, conduct a thorough inventory analysis:

| Inventory Category | Typical Weight Range | Recommended Shelf Capacity |

|---|---|---|

| Small Parts & Components | 5-50kg | 200kg per shelf |

| Medium Tools & Equipment | 50-150kg | 300kg per shelf |

| Heavy Items & Machinery | 150-350kg | 400kg per shelf |

| Mixed Inventory | Varies | 300-400kg per shelf |

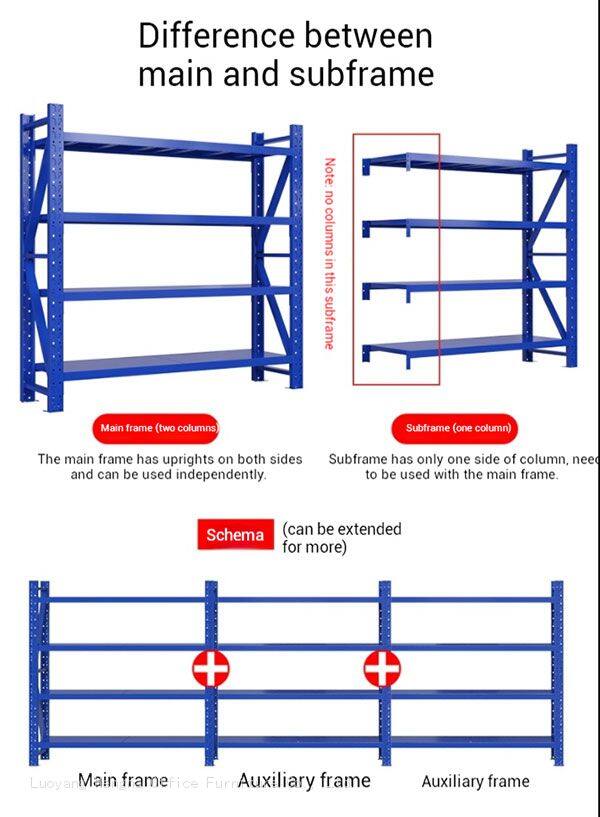

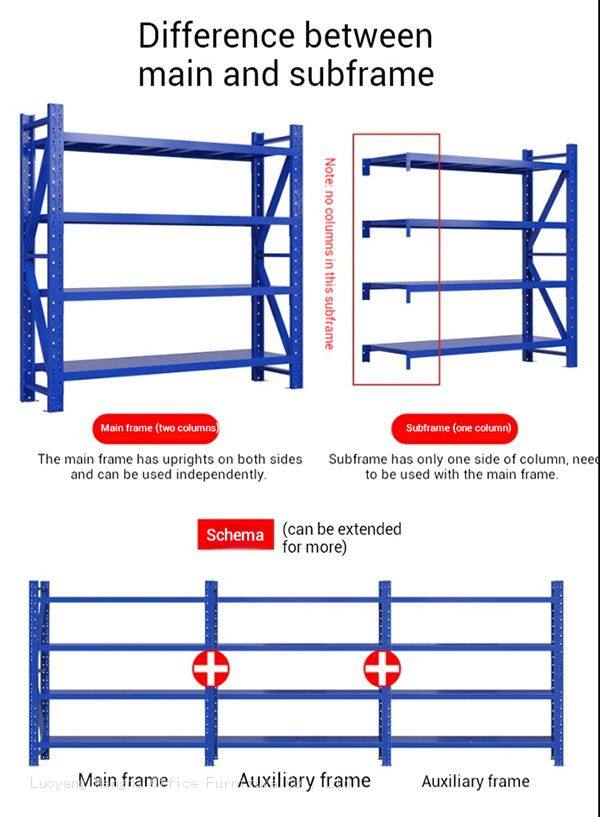

Space-Saving Design Features That Make a Difference

Modern industrial shelving systems incorporate numerous design innovations specifically aimed at maximizing space utilization. Understanding these features will help you select the most efficient system for your warehouse.

Vertical Space Optimization:

High-Capacity Vertical Storage: Systems that safely utilize ceiling height for additional storage

Multi-Layer Configuration: Multiple levels of storage within a single footprint

Adjustable Shelf Heights: Customize spacing to match your inventory dimensions

Narrow Aisle Designs: Reduce aisle width while maintaining accessibility

Floor Space Efficiency:

Small Footprint Design: Minimize the floor space occupied by the shelving structure itself

Freely Adjustable Efficiency: Reconfigure storage layout without purchasing new equipment

Multi-Layer Storage with Small Footprint: Maximize storage density while minimizing floor space usage

Flexible Layer Configuration: Adapt to different product sizes and seasonal inventory changes

The Game-Changing Benefits of Flexible Layer Configuration

One of the most significant advancements in industrial shelving is the development of flexible layer configuration systems. This feature alone can dramatically improve your warehouse space utilization.

What is Flexible Layer Configuration?

Flexible layer configuration refers to shelving systems that allow you to:

Adjust Shelf Heights: Move shelves up or down to accommodate different item sizes

Add or Remove Layers: Increase or decrease the number of storage levels as needed

Customize Spacing: Create custom spacing between shelves for optimal inventory organization

Reconfigure Quickly: Make changes without specialized tools or professional assistance

Real-World Benefits:

Adaptability to Seasonal Changes: Easily adjust for holiday inventory or seasonal products

Accommodate New Product Lines: Add new items without purchasing additional shelving

Optimize for Product Dimensions: Create perfect-fit storage for each product category

Improve Pick Efficiency: Organize items for faster order fulfillment

Layout Planning Tips for Maximum Space Utilization

Even the best shelving system won’t deliver optimal results without proper layout planning. Here are essential tips for designing your warehouse layout:

Layout Planning Process:

Conduct a Space Audit: Measure your available space and identify obstacles

Map Inventory Flow: Understand how products move through your warehouse

Plan for Growth: Leave room for expansion and changing needs

Consider Accessibility: Ensure all areas remain easily accessible

Optimal Layout Patterns:

U-Shaped Layout: Maximizes corner space and creates efficient workflow

Straight-Line Configuration: Ideal for linear product flow and easy navigation

Clustered Arrangement: Groups similar products together for efficient picking

High-Density Configuration: Minimizes aisle space while maintaining accessibility

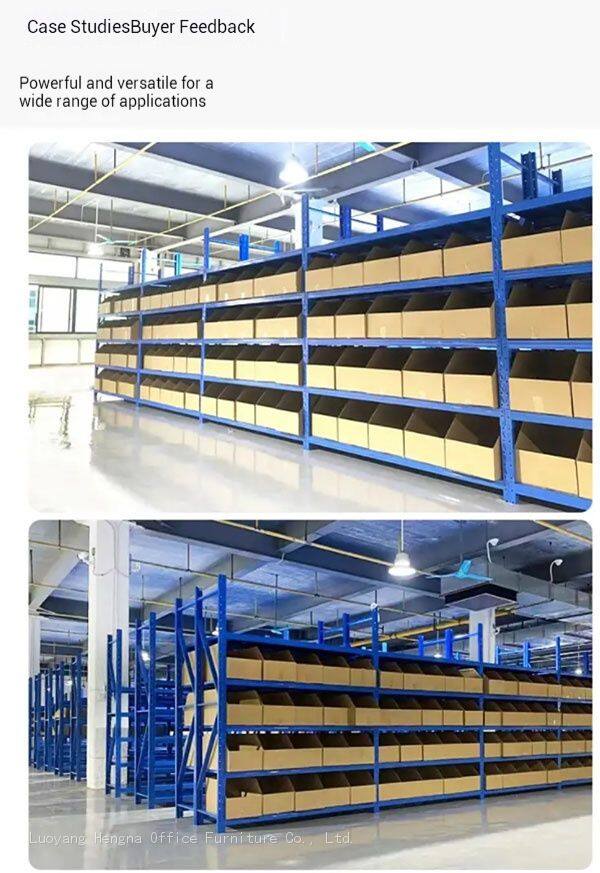

Real-World Applications and Success Stories

Seeing how other businesses have successfully implemented flexible industrial shelving can provide valuable insights for your own warehouse optimization project.

Case Study: Automotive Parts Distributor

A mid-sized automotive parts distributor was struggling with inefficient space utilization and slow order fulfillment times. By implementing 300kg capacity industrial shelving with flexible layer configuration, they achieved:

40% Increase in Storage Capacity: Same footprint, significantly more inventory

25% Faster Order Picking: Better organization and accessibility

30% Reduction in Errors: Clear organization and proper inventory placement

Complete ROI in 14 Months: Quick payback period due to efficiency gains

Case Study: E-commerce Fulfillment Center

An e-commerce business needed to accommodate rapid growth without expanding their facility. Their solution involved installing 400kg capacity shelving with multi-layer configuration:

60% More Storage in Same Space: Vertical optimization and dense packing

Scalable System: Easy to add units as business grew

Improved Employee Safety: Better organization reduced workplace accidents

Seasonal Flexibility: Easily adjusted for holiday inventory fluctuations

Implementation Checklist: Getting Started with Your New Shelving System

To ensure a successful implementation of your new industrial shelving system, follow this comprehensive checklist:

Pre-Implementation Planning:

[ ] Complete inventory analysis and weight assessment

[ ] Measure available space and create detailed layout plans

[ ] Determine specific capacity requirements for each area

[ ] Research and select appropriate shelving systems

[ ] Obtain necessary permits or approvals

Installation Process:

[ ] Prepare installation area (clean, level surface)

[ ] Schedule installation during low-activity periods

[ ] Train staff on proper use and maintenance

[ ] Implement inventory organization system

[ ] Test system with actual inventory loads

Post-Implementation:

[ ] Conduct safety inspection and certification

[ ] Establish regular maintenance schedule

[ ] Monitor efficiency improvements and ROI

[ ] Plan for future expansion or reconfiguration

Maximizing warehouse space with industrial shelving (200-400kg) featuring flexible layer configuration represents one of the most effective investments you can make in your operational efficiency. By carefully selecting the right system and implementing it thoughtfully, you can dramatically increase your storage capacity, improve workflow efficiency, and create a safer, more productive work environment.

The combination of optimal weight capacity, space-saving design, and flexible configuration options makes these shelving systems ideal for businesses looking to optimize their warehouse operations without the expense of facility expansion. Start your transformation today by assessing your current space utilization and exploring how modern industrial shelving solutions can help you achieve your warehouse optimization goals.

Tags: Maximize Warehouse Space, Choosing Industrial Shelving, Industrial Shelving (200-400kg) with Flexible Layer