Home > Blog > The Ultimate Guide to Organizing Workshop Tools with a Heavy Duty Tool Cart for Maximum Efficiency

-

Sarah

Hi there! Welcome to my shop. Let me know if you have any questions.

Sarah

Hi there! Welcome to my shop. Let me know if you have any questions.

Your message has exceeded the limit.

The Ultimate Guide to Organizing Workshop Tools with a Heavy Duty Tool Cart for Maximum Efficiency

2025-10-16 17:38:08

n every workshop, garage, or manufacturing facility, one common challenge plagues workers: tool organization. How many times have you wasted precious minutes searching for the right wrench, screwdriver, or drill bit? The solution to this universal problem is simpler than you might think: a heavy duty tool cart designed for maximum efficiency. This comprehensive guide will show you how organizing your tools with a quality tool cart can transform your workspace and skyrocket your productivity.

The Problem with Poor Tool Organization

Before we dive into the solution, let’s understand why tool organization matters so much:

Lost Time: Studies show that workers spend up to 20% of their time searching for tools

Frustration: Nothing kills momentum like not being able to find what you need

Damaged Tools: Tools left lying around get damaged, lost, or create safety hazards

Reduced Productivity: Every minute spent searching is a minute not spent working

Safety Risks: Cluttered workspaces lead to trips, falls, and accidents

Why a Heavy Duty Tool Cart is the Perfect Solution

A heavy duty tool cart addresses all these issues and more. Unlike fixed toolboxes or simple storage bins, a quality tool cart offers:

1. Mobility and Flexibility

With sturdy wheels, you can move your entire tool collection exactly where you need it. No more walking back and forth to a fixed storage location. This mobility is especially valuable in large workshops or when working on multiple projects simultaneously.

2. Ample Storage Space

Heavy duty tool carts come with multiple drawers, compartments, and often a pegboard system. This variety allows you to organize tools by type, size, or frequency of use.

3. Durability and Security

Built from tough materials like steel, these carts can withstand the harsh conditions of a workshop. Many also feature locking mechanisms to keep your valuable tools secure.

How to Organize Your Tools for Maximum Efficiency

Step 1: Sort and Categorize

Start by gathering all your tools in one place. Then sort them into categories:

Hand Tools: Wrenches, screwdrivers, pliers, hammers

Power Tools: Drills, saws, sanders, grinders

Measuring Tools: Tape measures, levels, calipers, squares

Fasteners: Nails, screws, bolts, nuts

Specialty Tools: Equipment specific to your trade

Step 2: Assign Storage Locations

Once sorted, assign each category to a specific area of your tool cart:

Top Drawer: Most frequently used hand tools

Middle Drawers: Power tools and accessories

Bottom Drawer: Heavy or less frequently used items

Pegboard: Tools you need to grab quickly

Side Compartments: Fasteners and small parts

Step 3: Use Organizers and Dividers

Maximize your drawer space with:

Drawer Dividers: Create custom-sized compartments for different tools

Foam Inserts: Cut foam to fit specific tools, preventing movement and damage

Magnetic Strips: Hold metal tools securely in place

Small Parts Containers: Keep screws, nails, and other small items organized

Essential Features to Look For

When choosing a heavy duty tool cart, consider these key features:

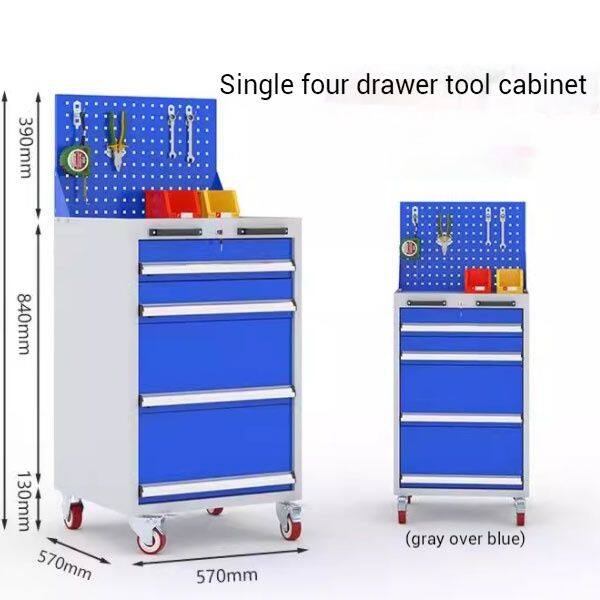

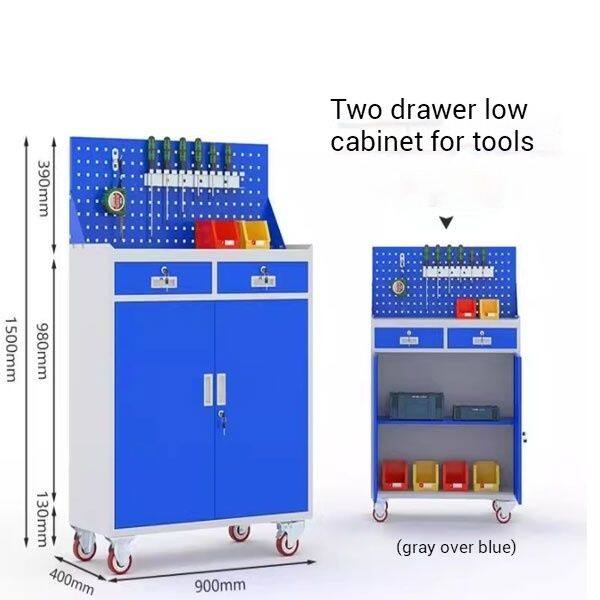

1. Drawer Configuration

Multiple Drawer Sizes: Different depths for various tool types

Smooth-Gliding Drawers: Ball-bearing slides for easy opening, even when full

Weight Capacity: Drawers that can support heavy tools without sagging

2. Mobility System

Heavy-Duty Casters: Wheels designed for workshop floors

Locking Brakes: Keep the cart stationary when in use

360° Swivel: Easy maneuverability in tight spaces

3. Construction Quality

Steel Frame: Durable and resistant to workshop chemicals

Powder Coating: Protects against scratches and rust

Reinforced Corners: Extra strength where it’s needed most

Benefits of Proper Tool Organization

1. Increased Productivity

Faster Access: Find any tool in seconds instead of minutes

Reduced Downtime: Spend more time working, less time searching

Better Workflow: Tools are where you need them, when you need them

2. Extended Tool Life

Protection: Tools stored properly last longer

Prevention: No more lost or damaged tools

Maintenance: Easier to keep tools clean and in good condition

3. Improved Safety

Reduced Clutter: Clear workspaces prevent accidents

Secure Storage: Heavy tools won’t fall or roll away

Ergonomic Access: Tools at comfortable heights reduce strain

Real-World Success Stories

Case Study: Automotive Repair Shop

A busy auto repair shop implemented heavy duty tool carts for each technician. Within three months:

Tool search time decreased by 75%

Productivity increased by 30%

Tool replacement costs dropped by 40%

Case Study: Woodworking Workshop

A custom furniture maker reorganized using a tool cart system:

Project completion time reduced by 25%

Customer satisfaction improved due to faster turnaround

Workshop safety incidents eliminated

Maintenance Tips for Your Tool Cart

Keep your tool cart in top condition with these simple practices:

Regular Cleaning: Wipe down surfaces weekly to remove dust and debris

Lubricate Drawers: Apply silicone spray to drawer slides every six months

Check Wheels: Inspect casters regularly for smooth operation

Tighten Hardware: Check and tighten screws and bolts monthly

Organize Daily: Return tools to their designated spots after each use

Tags: Guide to Organizing Workshop Tools, Workshop Tools with a Heavy Duty Tool Cart, Heavy Duty Tool Cart for Maximum Efficiency